25mm self drilling screws

Understanding 25mm Self-Drilling Screws A Comprehensive Guide

In the world of construction, manufacturing, and DIY projects, fasteners play a crucial role in ensuring the integrity and stability of structures. Among these fasteners, self-drilling screws have gained popularity for their efficiency and versatility. Specifically, 25mm self-drilling screws are a staple in various applications. This article will delve into the characteristics, benefits, and common uses of 25mm self-drilling screws.

What are Self-Drilling Screws?

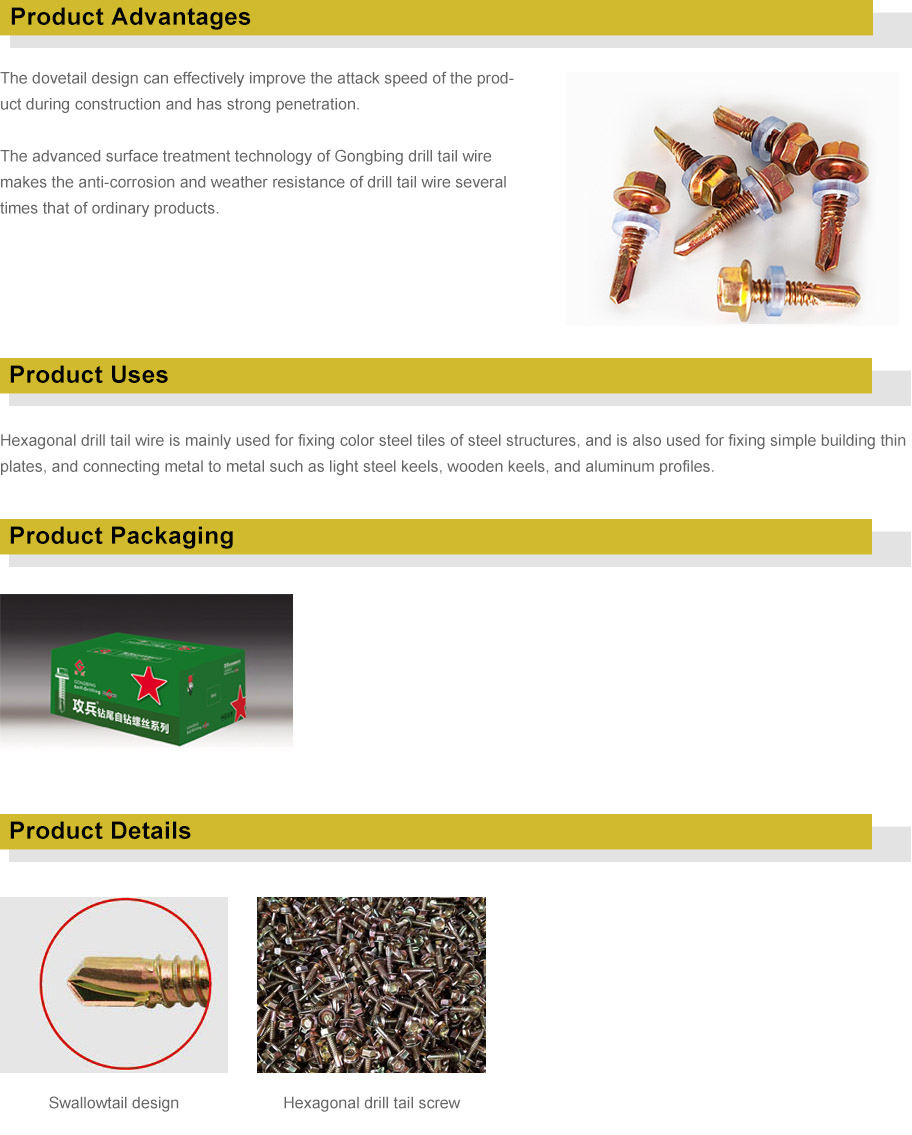

Self-drilling screws, also known as Tek screws, are specialized fasteners that can drill their own hole as they are driven into the material. They feature a unique design that incorporates a drill bit-like tip, allowing them to penetrate more easily into metals and other hard materials without the need for pre-drilling. This quality not only saves time but also reduces labor costs, making them a preferred choice for both professionals and DIY enthusiasts.

Key Features of 25mm Self-Drilling Screws

The specifications of a 25mm self-drilling screw can vary, but generally, they are characterized by certain features

1. Length As the name suggests, a 25mm self-drilling screw is 25 millimeters long, which is roughly equivalent to 1 inch. This length allows for sufficient engagement in various materials.

2. Material These screws are typically made from high-strength steel, often with a zinc coating for corrosion resistance. This enhances their durability, making them suitable for both indoor and outdoor applications.

3. Thread Design The threading on self-drilling screws is specifically designed to provide maximum grip on the materials being joined. The threads often extend all the way up to the head, allowing for secure fastening in a variety of substrates.

4. Head Type Self-drilling screws come with different head types, such as hexagon, Phillips, or Torx, depending on the requirements of the project. The choice of head can significantly affect the ease of installation and the type of tool needed.

Benefits of Using 25mm Self-Drilling Screws

1. Time Efficiency One of the primary advantages of using self-drilling screws is the time savings they offer. Installation is straightforward and quick, as there is no need for pre-drilling holes.

25mm self drilling screws

2. Cost-Effectiveness By reducing the labor involved in fastening materials, self-drilling screws can help decrease overall project costs. This is particularly beneficial for large-scale operations where time and labor are critical factors.

3. Versatility 25mm self-drilling screws can be used in a range of applications, including metal sheeting, wood framing, masonry, and more. Their adaptability makes them suitable for various construction and repair tasks.

4. Strong Hold The self-tapping design of these screws ensures a tight fit, reducing the risk of loosening over time. This is particularly important in structural applications where safety and stability are paramount.

Common Applications

25mm self-drilling screws are widely used in various industries and applications, such as

- Construction These screws are commonly employed in the assembly of steel structures, metal roofing, and siding due to their capacity to securely fasten metal to metal.

- HVAC Installations In heating, ventilation, and air conditioning (HVAC) systems, self-drilling screws provide a reliable method for securing ductwork and other components.

- Automotive Industry They are also frequently found in automotive assembly processes where metal parts need to be joined quickly and securely.

- Home Improvement Projects DIY enthusiasts appreciate the simplicity and efficiency of these screws when tackling various home improvement tasks, from building furniture to installing shelves.

Conclusion

In conclusion, 25mm self-drilling screws are a vital tool in modern construction and manufacturing. Their unique design combines efficiency, strength, and versatility, making them ideal for a wide range of applications. Whether you are a professional contractor or a DIY lover, incorporating self-drilling screws into your toolkit can undoubtedly enhance your productivity and streamline your projects. When selecting the right screw for your tasks, consider factors such as material compatibility, load requirements, and environmental conditions to ensure the best performance.

-

Weatherproof Plastic Expansion Anchors for OutdoorNewsJun.06,2025

-

Sustainability in the Supply Chain: Eco-Friendly TEK Screws ProductionNewsJun.06,2025

-

Load-Bearing Capacity of External Insulation FixingsNewsJun.06,2025

-

Double Head Bolts: Enhancing Efficiency in Industrial MachineryNewsJun.06,2025

-

Corrosion Resistance in Chipboard Screws: Coatings for Wholesale DurabilityNewsJun.06,2025

-

Butterfly Toggle Bolts : Enhancing Structural ResilienceNewsJun.06,2025