Heavy Duty Tek Screws for Robust Construction and Reliable Fastening Solutions

Understanding Heavy Section Tek Screws Features and Applications

When it comes to construction and manufacturing, the choice of fasteners plays a critical role in ensuring the stability and longevity of structures. Among various types of fasteners, heavy section Tek screws have gained immense popularity due to their robust design and versatility. This article delves into the characteristics, applications, and advantages of heavy section Tek screws, helping professionals make informed decisions in their respective fields.

What are Heavy Section Tek Screws?

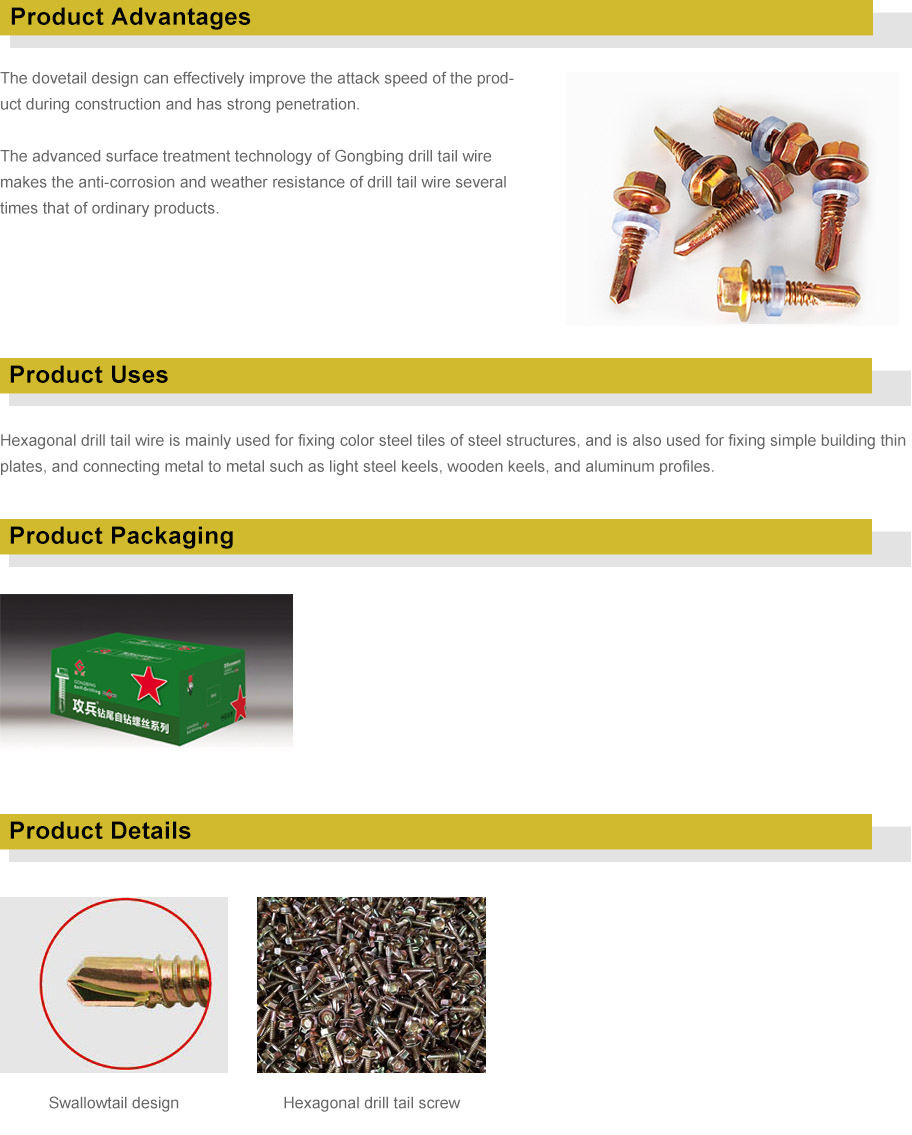

Heavy section Tek screws are self-tapping screws designed for use in thicker metal sections. They are specifically engineered to penetrate heavy gage materials, such as steel or aluminum, without the need for pre-drilling. These screws feature a spiral thread that assists in creating a strong bond and minimizes stripping, making them ideal for high-stress applications. Typically made from durable materials such as steel, these screws often come with a corrosion-resistant coating to ensure longevity, even in harsh environments.

Key Features of Heavy Section Tek Screws

1. Self-Tapping Design One of the most significant advantages of heavy section Tek screws is their self-tapping capability. The specialized tip of the screw allows it to create its own pilot hole as it is driven into the material, saving time and labor costs during installation.

2. High Pull-Out Strength Due to their robust construction and precise threading, heavy section Tek screws provide superior pull-out strength. This feature is crucial when securing heavy components or machinery to avoid potential failures.

3. Variety of Head Styles These screws come in various head styles, including hex, pan, and flat heads, allowing engineers and builders to choose the right type based on aesthetic preferences, available tools, and specific application requirements.

4. Corrosion Resistance Many heavy section Tek screws are treated with finishes such as zinc plating or hot-dip galvanizing to enhance their resistance to rust and corrosion, making them suitable for outdoor and harsh environments.

heavy section tek screws

5. Versatility Heavy section Tek screws can be used in an array of applications, including metal roofing, structural steel assembly, and automotive manufacturing. Their adaptability makes them a preferred choice across multiple industries.

Applications of Heavy Section Tek Screws

Due to their unique features, heavy section Tek screws are extensively used in various sectors

1. Construction In construction, these screws are instrumental in fastening metal panels to steel framing. Their capacity to penetrate heavy gauge materials makes them appropriate for both residential and commercial buildings.

2. Automotive Industry The automotive sector relies on heavy section Tek screws to assemble various components of vehicles, ensuring that parts remain securely in place while also offering resistance to vibrations and shocks.

3. Manufacturing In manufacturing settings, these screws are used to assemble machinery and equipment where durability and reliability are paramount.

4. Roofing Metal roofing installations often employ heavy section Tek screws to ensure that roofing panels are securely attached to the underlying structure. The self-tapping nature of these screws speeds up the installation process and enhances the overall strength of the roof.

Conclusion

In summary, heavy section Tek screws are a vital component in the toolkit of construction and manufacturing professionals. Their self-tapping design, high pull-out strength, variety of head styles, and corrosion resistance make them ideal for a range of applications, from buildings and vehicles to industrial equipment. By choosing the right type of heavy section Tek screw, builders and manufacturers can significantly enhance the integrity and longevity of their projects. Understanding the features and benefits of these fasteners not only promotes effective use but also fosters confidence in the overall quality of the construction and manufacturing processes. As technology continues to advance, the evolution of heavy section Tek screws promises even greater reliability and efficiency for future applications.

-

Weatherproof Plastic Expansion Anchors for OutdoorNewsJun.06,2025

-

Sustainability in the Supply Chain: Eco-Friendly TEK Screws ProductionNewsJun.06,2025

-

Load-Bearing Capacity of External Insulation FixingsNewsJun.06,2025

-

Double Head Bolts: Enhancing Efficiency in Industrial MachineryNewsJun.06,2025

-

Corrosion Resistance in Chipboard Screws: Coatings for Wholesale DurabilityNewsJun.06,2025

-

Butterfly Toggle Bolts : Enhancing Structural ResilienceNewsJun.06,2025