self drilling screws galvanized

Understanding Self-Drilling Screws Galvanized A Comprehensive Guide

Self-drilling screws, commonly known as self-tappers, are an essential component in the world of construction and metalwork. Their unique design allows them to create their own hole as they are driven into materials, eliminating the need for pre-drilling. When these screws are galvanized, they gain additional benefits that enhance their performance and longevity, making them a preferred choice in various applications.

What are Galvanized Self-Drilling Screws?

Galvanization is a process that involves coating steel or iron with a layer of zinc to protect it from corrosion and rust. Self-drilling screws made from galvanized steel are particularly beneficial in environments where moisture is prevalent. The zinc coating acts as a sacrificial barrier, preventing rust while ensuring the structural integrity of the screw.

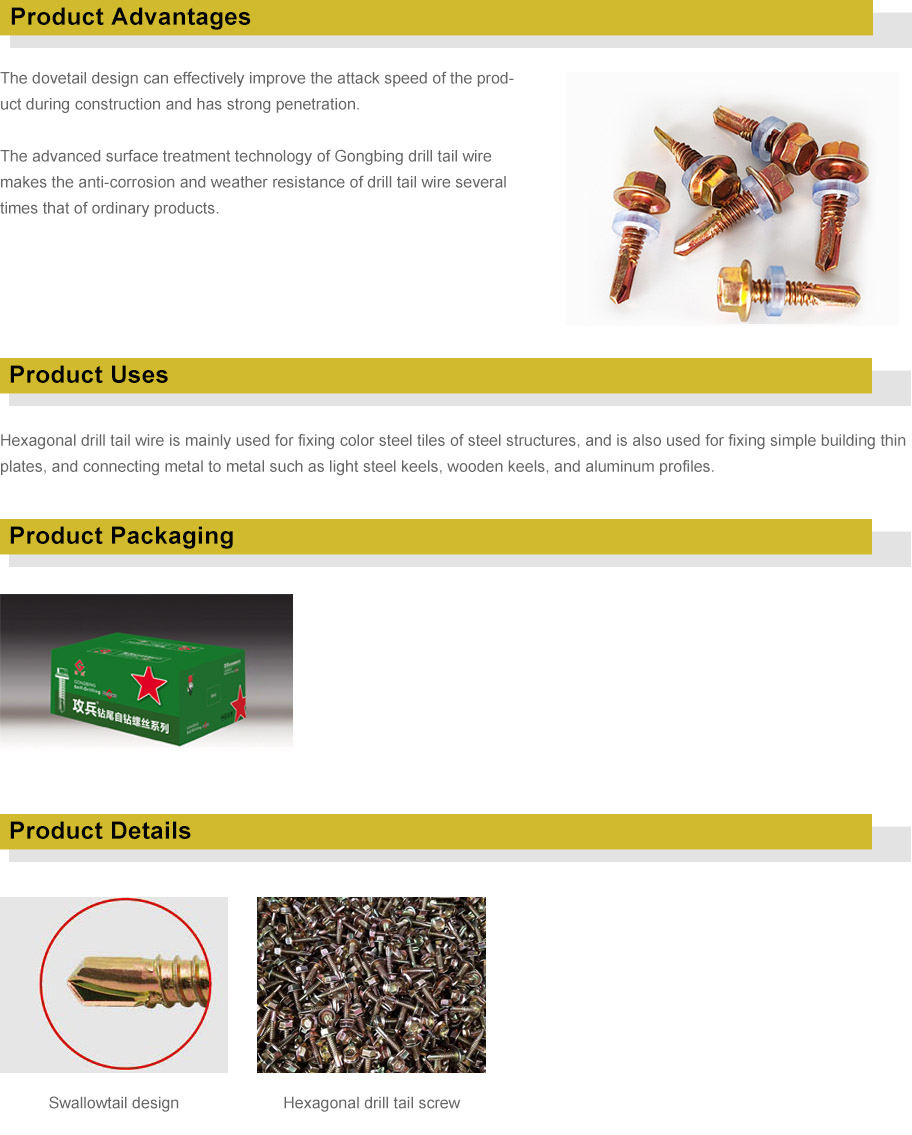

These screws feature a sharp drill point that cuts through materials like wood and metal, which makes them ideal for construction projects that require fast and reliable fastening solutions. They come in various sizes and types, catering to a wide array of applications.

Advantages of Galvanized Self-Drilling Screws

1. Corrosion Resistance One of the most significant advantages of using galvanized self-drilling screws is their resistance to corrosion. In outdoor environments or in settings where exposure to water is common, these screws can withstand the elements much better than their non-galvanized counterparts.

2. Time Efficiency The self-drilling capability of these screws eliminates the need for pilot holes. This feature not only saves time but also increases productivity in construction projects, allowing workers to fasten materials together quickly and efficiently.

3. Versatility Galvanized self-drilling screws can be used on a variety of substrates including wood, metal, and plastic. This versatility makes them suitable for numerous applications, from roofing and siding to electrical boxes and metal fabrication.

4. Strength and Durability These screws are designed to provide strong holding power, making them highly durable in demanding applications. The combination of the hardened steel construction and galvanization ensures that they maintain their integrity over time, even under stress.

Applications of Galvanized Self-Drilling Screws

self drilling screws galvanized

Galvanized self-drilling screws are widely used across various industries. They are commonly employed in

- Construction and Roofing They are often used to fasten metal roofing sheets and other external structures due to their resistance to weather-related wear. - Automotive Industry In automotive manufacturing, these screws are utilized to assemble various metal components, where strength and reliability are paramount. - HVAC Systems When installing ductwork or other HVAC components, galvanized self-drilling screws provide a secure connection that can resist rust in humid environments.

- Electronics and Appliances These screws help assemble casings and frames for electronic appliances, providing a strong hold and reducing the risk of corrosion that could affect the functionality of devices.

Selection Tips

When choosing galvanized self-drilling screws, consider the following

1. Material Type Ensure that the screw is compatible with the materials you are fastening. Different substrates may require screws with specific thread designs.

2. Coating Thickness Pay attention to the thickness of the galvanization, as thicker coatings provide better corrosion resistance.

3. Length and Diameter Choose the correct length and diameter based on your specific application needs to ensure optimal performance.

4. Head Type Various head types (such as hex, pan, or flat) are available; select one that complements your assembly requirements.

Conclusion

Self-drilling screws galvanized are a practical solution for both professional and DIY projects. Their ability to withstand rust and corrosion, combined with their ease of use and versatility, makes them a valuable addition to any toolbox. Whether you’re working on a construction site, in metal fabrication, or tackling a home improvement project, understanding the benefits and applications of these screws will help ensure the success of your endeavors.

-

Weatherproof Plastic Expansion Anchors for OutdoorHabariJun.06,2025

-

Sustainability in the Supply Chain: Eco-Friendly TEK Screws ProductionHabariJun.06,2025

-

Load-Bearing Capacity of External Insulation FixingsHabariJun.06,2025

-

Double Head Bolts: Enhancing Efficiency in Industrial MachineryHabariJun.06,2025

-

Corrosion Resistance in Chipboard Screws: Coatings for Wholesale DurabilityHabariJun.06,2025

-

Butterfly Toggle Bolts : Enhancing Structural ResilienceHabariJun.06,2025