Abstract

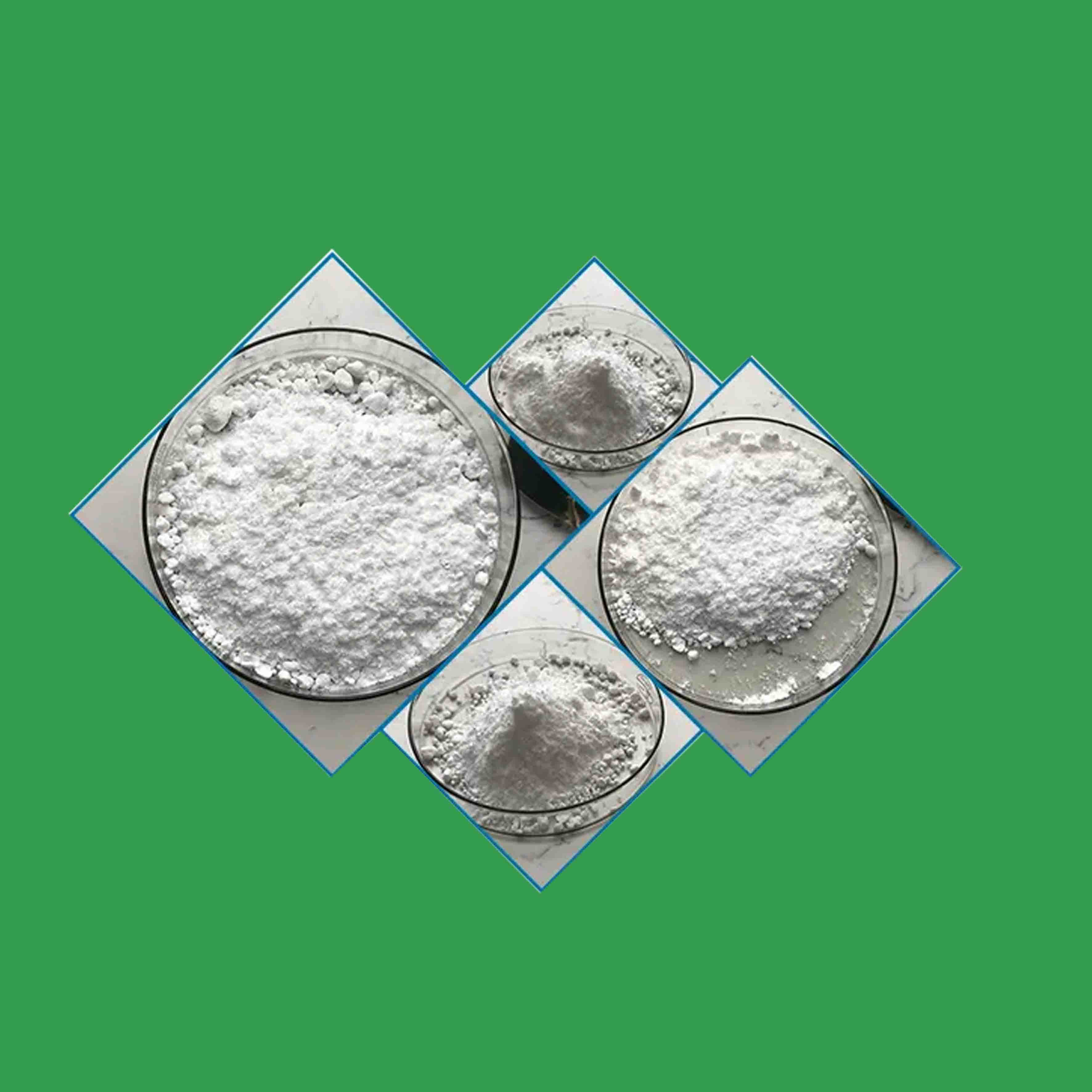

Titanium Dioxide/TiO2/Titanium Oxide Free Sample

Additionally, environmental regulations and compliance costs, which are increasingly stringent in China, can add to the overall production expenses, impacting the final price Additionally, environmental regulations and compliance costs, which are increasingly stringent in China, can add to the overall production expenses, impacting the final price

Additionally, environmental regulations and compliance costs, which are increasingly stringent in China, can add to the overall production expenses, impacting the final price Additionally, environmental regulations and compliance costs, which are increasingly stringent in China, can add to the overall production expenses, impacting the final price china lithopone pigment pricelist.

china lithopone pigment pricelist.Wholesale suppliers of lithopone typically offer quotes for bulk orders to businesses and industrial customers. These quotes are based on factors such as quantity, purity, and particle size. When requesting wholesale lithopone MSDS quotes, it is important to consider the following key points

factory price tio2 titanium dioxide manufacturer. With our commitment to quality and excellence, customers can have peace of mind knowing that they are getting genuine and reliable products.

cl 77891 titanium dioxide supplier. Our commitment to excellence extends beyond simply providing the raw material; we also offer technical support and guidance to help our customers achieve optimal results in their applications.

cl 77891 titanium dioxide supplier. Our commitment to excellence extends beyond simply providing the raw material; we also offer technical support and guidance to help our customers achieve optimal results in their applications.TiO2 powder is also widely used in the cosmetics industry, where it is used as a whitening agent in skincare products, sunscreen, and makeup. TiO2 powder suppliers work closely with cosmetic manufacturers to ensure that they have a reliable and high-quality supply of TiO2 powder to meet the demands of their consumers.

tio2 types suppliers. With a strong focus on research and development, Tronox is able to provide cutting-edge TiO2 solutions that meet the highest quality standards.

In addition to China, there are also many titanium dioxide powder factories in other countries such as the United States, Japan, and Germany In addition to China, there are also many titanium dioxide powder factories in other countries such as the United States, Japan, and Germany

In addition to China, there are also many titanium dioxide powder factories in other countries such as the United States, Japan, and Germany In addition to China, there are also many titanium dioxide powder factories in other countries such as the United States, Japan, and Germany titanium dioxide powder factories. These factories compete with each other in terms of product quality, price, and service to meet the needs of different customers.

titanium dioxide powder factories. These factories compete with each other in terms of product quality, price, and service to meet the needs of different customers.Various titanium-rich minerals, including ilmenite and rutile, can serve as starting materials for the production of highly purified Titanium Dioxide. The predominant method employed in Titanium Dioxide production is the chloride process. In this process, the mineral, along with coke and chlorine, undergoes a reaction within a fluidized bed, resulting in the formation of primarily titanium tetrachloride and carbon dioxide. Subsequently, the titanium tetrachloride undergoes purification and conversion to Titanium Dioxide. Another method involves treating ilmenite with sulfuric acid to manufacture the chemical.

High-quality barium sulfate is essential for many applications, so it is worth investing in a reputable manufacturer that offers a reliable product High-quality barium sulfate is essential for many applications, so it is worth investing in a reputable manufacturer that offers a reliable product

High-quality barium sulfate is essential for many applications, so it is worth investing in a reputable manufacturer that offers a reliable product High-quality barium sulfate is essential for many applications, so it is worth investing in a reputable manufacturer that offers a reliable product