Moreover, the plastic material absorbs vibrations, reducing the risk of loosening over time. This makes them suitable for installations that require stability, such as shelves, cabinets, and heavy-duty fixtures This makes them suitable for installations that require stability, such as shelves, cabinets, and heavy-duty fixtures

The evolution of industrial overlock sewing machines has brought about significant technological advancements. Modern machines now come equipped with features such as automatic threading, adjustable stitch lengths, and digital interfaces that simplify operation. Some models even include multifunctional capabilities, allowing users to switch between different types of stitches with ease.

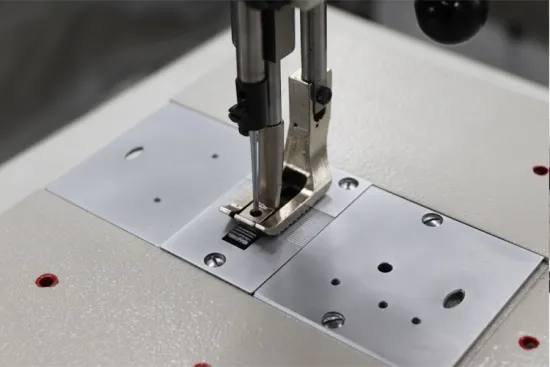

5. Durability and Build Quality Heavy-duty machines are typically constructed from metal, making them more durable than plastic-framed counterparts. Investing in a sturdy machine ensures longevity, even under heavy use.

- Shuttle Hook Case A Comprehensive Guide

Eco-Friendly Practices

Conclusion

Versatility in Applications

The Rise of Leather Sewing Machine Companies Crafting Quality and Precision

In the realm of textile manufacturing, efficiency and precision are paramount. Among the plethora of sewing machines available, industrial overlock sewing machines have carved a niche for themselves, becoming indispensable tools in the garment industry. These machines, often referred to as sergers or overlockers, perform a unique function that significantly enhances the quality of fabric seams and the overall durability of garments.

1. Singer Heavy Duty 4423 This machine features a strong motor, a stainless steel bedplate for smooth fabric feeding, and an array of stitch options. It’s a popular choice for beginners and experienced sewists alike.

In the realm of modern manufacturing, especially within the packaging industry, the significance of jumbo bags cannot be understated. These large, woven polypropylene bags, often referred to as FIBCs (Flexible Intermediate Bulk Containers), are essential for storing and transporting bulk materials across various sectors, including agriculture, chemicals, and pharmaceuticals. As the demand for these bags surges, so does the need for efficient and robust jumbo bag sewing machinery, which plays a crucial role in the production process.

Overlockers are incredibly versatile, offering various stitch types to accommodate different fabric types and garment needs. The most common stitches include the 3-thread overlock, which is ideal for lightweight fabrics, and the 4-thread overlock, perfect for medium-weight materials. Additionally, overlockers can perform rolled hems, gathering stitches, and even flatlock stitches, making them invaluable for both home sewers and professional tailors.

- When shopping for a long arm upholstery sewing machine, there are a few key factors to consider. First and foremost, it is important to choose a machine with a powerful motor that can handle heavy fabrics and multiple layers of material. Additionally, look for a machine with a wide range of stitch options and adjustable settings to accommodate different types of projects.

- One of the key advantages of using a 2% needle lockstitch machine is its ability to sew at high speeds without compromising on stitch quality. This makes it a valuable tool for businesses that require fast and efficient stitching, such as clothing factories and upholstery workshops.

Considerations When Choosing an Industrial Sewing Machine

The robustness of cylindrical bed sewing machines caters to high-volume production environments

. Designed to withstand the rigors of continuous use, these machines are built with durable components that minimize wear over time, ensuring longevity and reducing maintenance costs. This reliability allows manufacturers to focus on output without the constant worry of machine breakdowns.- If you are a beginner or hobbyist sewer, you may not need to invest in a top-of-the-line overlock sewing machine. There are plenty of affordable options available that still provide excellent results. Many entry-level machines come with basic features such as adjustable stitch length and width, differential feed, and multiple thread capabilities. These machines are great for beginners who are just starting out and want to experiment with different sewing techniques.

Changing needles regularly is important to avoid damage to the fabric and to maintain consistent stitch quality. It’s also advisable to use the correct type of needle for the fabric being sewn, as this will enhance both performance and stitch appearance.

4. Stitch Types and Lengths

sewing machine to sew thick material

In addition to its strength and durability, a HD sewing machine often comes equipped with a range of useful features to enhance your sewing experience. Many models offer a variety of stitches, adjustable speed settings, and automatic needle threaders, making sewing faster and more efficient. Some machines even come with special accessories like walking feet or quilting guides to help you tackle specific projects with ease.

4. Sewing Technique When executing top stitching, guide the fabric slowly and steadily while keeping the edges aligned. Maintaining even pressure on the fabric helps achieve the desired look. For those seeking a more decorative effect, consider varying the stitch length or using colored thread to create visual interest.

Moreover, machine stitching allows for techniques such as edge finishing, reinforcing seams, and applying decorative stitches, thus broadening the scope of what can be achieved in leatherwork. This blend of machine efficiency and artisan creativity results in high-quality products that appeal to a wide range of consumers.

Generally, the price of double needle sewing machines can range from as low as $200 for basic models to upwards of $3,000 or more for top-of-the-line, industrial-grade machines. A mid-range machine typically falls between $500 and $1,500, making it accessible for hobbyists and small businesses looking for quality without breaking the bank.

Understanding Heavy Duty Hand Stitching Machines

Overall, the 2% needle industrial sewing machine is a valuable tool for businesses in the textile industry. Its speed, precision, and versatility make it a reliable choice for a wide range of sewing tasks. Whether you are sewing garments, upholstery, or accessories, this machine can help you achieve professional results in a fraction of the time it would take with a traditional sewing machine.

5. Adding Decorative Elements

Factors Influencing Price

When looking for a chain stitch sewing machine for sale, it is essential to consider the following options

Contrast this with Jane, a professional upholsterer who initially invested in a heavy-duty machine costing $700. Over six years, she spent an average of $50 annually on maintenance—her total over six years: $1000.

the cub leather sewing machine.

One of the primary advantages of using the double needle stretch stitch is its durability. Traditional straight stitches may break when sewing on stretchy materials because they do not have the ability to stretch. The double needle stretch stitch, on the other hand, provides the necessary give, allowing for comfortable movement in garments. This is particularly important in activewear, dance costumes, and other garments designed for dynamic activities.

Optimizing Overlock Machine Costs

2. Stitch Width

D. Outdoor Gear and Bags:

Readers will find inspiration for sewing outdoor gear like backpacks, tents, and camping accessories that require the durability and strength provided by heavy duty machines.

Furthermore, the durability of jute bags coupled with the efficient sealing provided by these machines ensures that products are well-protected during transit. Jute bags are strong and capable of carrying heavy loads, making them ideal for agricultural products such as grains, coffee, and spices. By utilizing jute bag closer machines, manufacturers can ensure that their products remain secure and intact, which can enhance customer satisfaction and foster brand loyalty.

heavy duty leather sewing machine. These machines are typically equipped with a range of stitch options, including straight stitches, zigzag stitches, and decorative stitches, allowing you to create a variety of finished looks on your leather projects. Some machines even offer programmable stitch settings, giving you even more control over the final outcome of your sewing.

Another significant aspect is the variety of stitch types available. Many heavy-duty machines offer straight, zigzag, and decorative stitches, enabling users to customize their projects. Additionally, adjustable settings for stitch length and width provide further versatility, ensuring that specific requirements for different materials or designs can be easily achieved.

This makes them suitable for installations that require stability, such as shelves, cabinets, and heavy-duty fixtures This makes them suitable for installations that require stability, such as shelves, cabinets, and heavy-duty fixtures

This makes them suitable for installations that require stability, such as shelves, cabinets, and heavy-duty fixtures This makes them suitable for installations that require stability, such as shelves, cabinets, and heavy-duty fixtures