- Outdoor Installations Due to their corrosion-resistant properties, these anchors are well-suited for outdoor applications, including securing fencing, signage, and other outdoor fixtures.

...

2025-08-14 03:25

1938

The sharp point enables easy penetration into the material without pre-drilling, saving time and effort The sharp point enables easy penetration into the material without pre-drilling, saving time and effort

The sharp point enables easy penetration into the material without pre-drilling, saving time and effort The sharp point enables easy penetration into the material without pre-drilling, saving time and effort

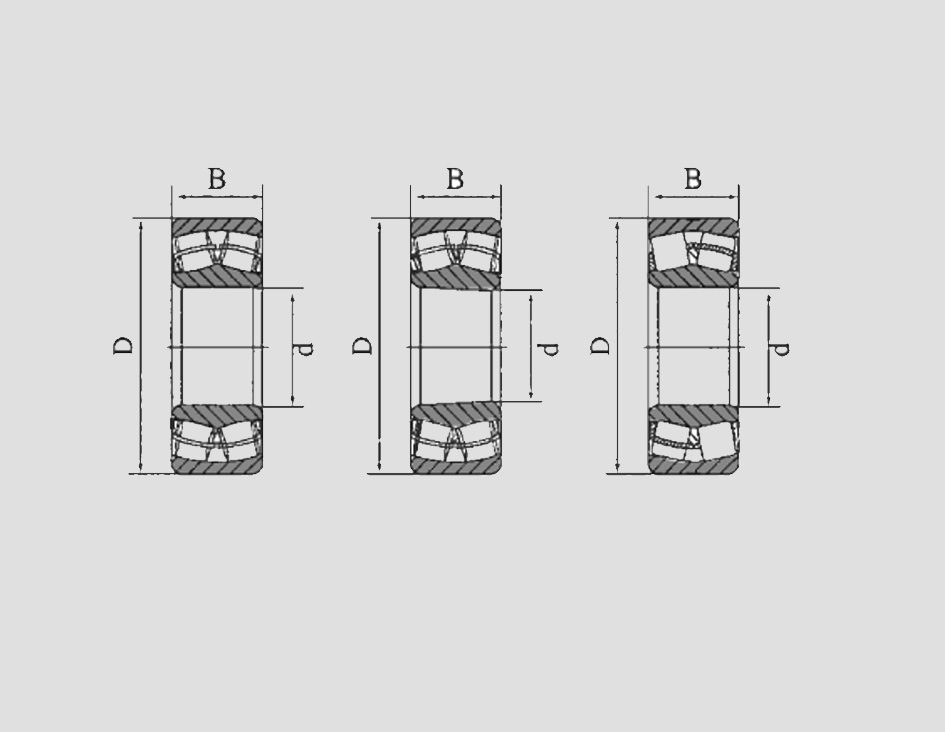

The double shields provide effective protection against contaminants, while the cage maintains the proper spacing between the balls, ensuring efficient rotation The double shields provide effective protection against contaminants, while the cage maintains the proper spacing between the balls, ensuring efficient rotation

The double shields provide effective protection against contaminants, while the cage maintains the proper spacing between the balls, ensuring efficient rotation The double shields provide effective protection against contaminants, while the cage maintains the proper spacing between the balls, ensuring efficient rotation With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating

With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating However, specialized or custom-made cylindrical roller bearings, designed to meet specific application requirements, may come at a premium due to the additional engineering and customization involved However, specialized or custom-made cylindrical roller bearings, designed to meet specific application requirements, may come at a premium due to the additional engineering and customization involved

However, specialized or custom-made cylindrical roller bearings, designed to meet specific application requirements, may come at a premium due to the additional engineering and customization involved However, specialized or custom-made cylindrical roller bearings, designed to meet specific application requirements, may come at a premium due to the additional engineering and customization involved This results in a longer service life and lower maintenance costs, making it a cost-effective choice for businesses looking to optimize their operations This results in a longer service life and lower maintenance costs, making it a cost-effective choice for businesses looking to optimize their operations

This results in a longer service life and lower maintenance costs, making it a cost-effective choice for businesses looking to optimize their operations This results in a longer service life and lower maintenance costs, making it a cost-effective choice for businesses looking to optimize their operations