Titanium dioxide, a versatile and widely used material, finds its application in various industries including the rubber industry

. This white pigment is known for its excellent UV resistance, durability, and opacity, making it an ideal choice for enhancing the properties of rubber products.

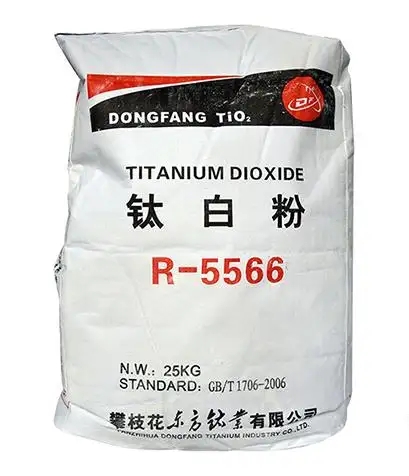

factory price tio2 titanium dioxide suppliers. This ensures that manufacturers receive a consistent supply of Tio2 that meets their production requirements.

Drivers

It is generally more expensive than lithopone and may not be as environmentally friendly It is generally more expensive than lithopone and may not be as environmentally friendly

It is generally more expensive than lithopone and may not be as environmentally friendly It is generally more expensive than lithopone and may not be as environmentally friendly lithopone and titanium dioxide. The production process for TiO2 involves the use of hazardous chemicals, and its disposal can be problematic. Additionally, TiO2 has a tendency to agglomerate, which can affect its performance in certain applications.

lithopone and titanium dioxide. The production process for TiO2 involves the use of hazardous chemicals, and its disposal can be problematic. Additionally, TiO2 has a tendency to agglomerate, which can affect its performance in certain applications.What is titanium dioxide?

Recent analyses of food-grade TiO2 samples have found that a significant portion of particles may be within the nanoscale. These particles (also known as nanoparticles) range in size from 1 to 100 nm, where 1 nm equals 1 billionth of a metre (the width of a typical human hair is 80,000 to 100,000 nm).

We offer specialized TIO2 products that comply with strict regulatory standards, ensuring safety and efficacy in these sensitive applications We offer specialized TIO2 products that comply with strict regulatory standards, ensuring safety and efficacy in these sensitive applications

We offer specialized TIO2 products that comply with strict regulatory standards, ensuring safety and efficacy in these sensitive applications We offer specialized TIO2 products that comply with strict regulatory standards, ensuring safety and efficacy in these sensitive applications tio2 products supplier.

tio2 products supplier.The conventional surface treatment methods of titanium alloy include glow discharge plasma deposition, oxygen ion implantation, hydrogen peroxide treatment, thermal oxidation, sol-gel method, anodic oxidation, microarc oxidation, laser alloying, and pulsed laser deposition. These methods have different characteristics and are applied in different fields. Glow discharge plasma deposition can get a clean surface, and the thickness of the oxide film obtained is 2 nm to 150 nm [2–8]. The oxide film obtained from oxygen ion implantation is thicker, about several microns [9–14]. Hydrogen peroxide treatment of titanium alloy surface is a process of chemical dissolution and oxidation [15, 16]. The dense part of the oxide film is less than 5 nm [17–21]. The oxide film generated from the thermal oxidation method has a porous structure, and its thickness is commonly about 10-20 μm [22–25]. The oxide film from the sol-gel method is rich in Ti-OH, a composition that could induce apatite nucleation and improve the combining of implants and bone. It has a thickness of less than 10 μm [26–28]. Applied with the anodic oxidation method, the surface can generate a porous oxide film of 10 μm to 20 μm thickness [29–31]. Similarly, the oxide film generated from the microarc oxidation method is also porous and has a thickness of 10 μm to 20 μm [32, 33].

Par ailleurs, dès lors que l'on recherche une certain transparence dans les travaux artistiques, son pouvoir opacifiant et son pouvoir dégradant des couleurs pas trop élevés le désignent pour remplacer le dioxyde de titane trop opaque et trop dégradant (§ Des Liants et des couleurs aux éditions EREC)

sachtleben tio2 manufacturer. By collaborating with industry experts and investing in scientific research, they have developed specialized TiO2 grades tailored for specific customer needs. These include high-gloss TiO2 for automotive paints, ultra-fine grades for printing inks, and even TiO2 variants designed for use in food and pharmaceuticals, adhering to stringent safety regulations.

sachtleben tio2 manufacturer. By collaborating with industry experts and investing in scientific research, they have developed specialized TiO2 grades tailored for specific customer needs. These include high-gloss TiO2 for automotive paints, ultra-fine grades for printing inks, and even TiO2 variants designed for use in food and pharmaceuticals, adhering to stringent safety regulations.