What is Vulcanizing Tape?

The design of a control box is a thoughtful process, taking into consideration various factors that affect its performance:

The design and manufacturing of fire-resistant electrical tape are subject to rigorous testing to meet specific safety standards. When choosing electrical tape for a project, it is crucial to ensure that it is certified by relevant regulatory bodies, such as Underwriters Laboratories (UL) or the International Electrotechnical Commission (IEC). These certifications indicate that the tape has been tested for its fire-resistant properties, assuring users that they are making a safe choice.

- Conclusion

Useful applications

- Gymnasium floor tape, a seemingly insignificant element in the grand scheme of athletic facilities, plays an essential role in ensuring safety and optimizing performance within these dynamic spaces. This humble strip of tape, often overlooked, is a vital tool for outlining areas, marking boundaries, and promoting a structured environment that fosters both physical activity and sportsmanship.

(1) The thermal stability is 180 ℃. At this temperature, the product can be used safely for more than 10 years, saving many after-sales troubles;

- In terms of maintenance, PVC insulation tape is relatively low-maintenance. Its durable nature means it withstands weathering and aging effectively, ensuring a long service life. However, like any other material, it requires proper handling and storage to maintain its optimal performance.

- 4. Thermal management The tape can be used to dissipate heat from electronic components, preventing overheating and potential failure.

These boxes aren’t one-size-fits-all. They come tailor-made to suit specific environments and applications, ensuring that they’re up to the task, whether on a factory floor or in an outdoor setting.

- Another significant advantage of clear waterproof flex tape is its resistance to UV rays. Unlike many other tapes that tend to degrade when exposed to sunlight, this tape maintains its integrity and remains effective for years to come. This makes it an excellent choice for outdoor applications, such as sealing the edges of decks, patios, and boats.

- Another advantage of aisle marking tape is its versatility and durability. Most tapes are made from high-quality materials that can withstand heavy traffic, harsh chemicals, and extreme temperatures. This ensures that the tape will remain intact and visible for an extended period, providing long-lasting benefits for businesses.

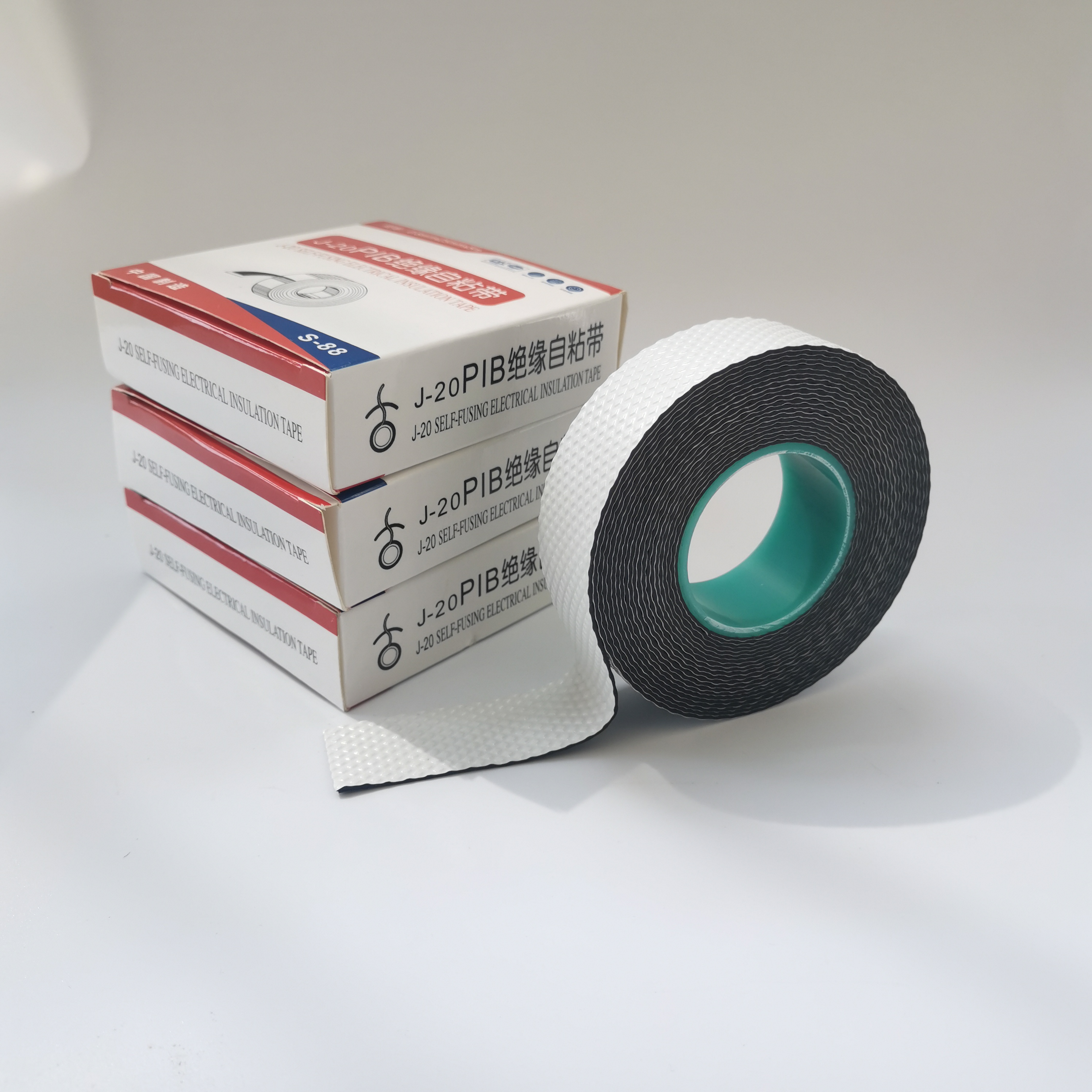

What is Self-Fusing Silicone Electrical Tape?

3. Ease of Application Repairing leaks does not have to be a labor-intensive task. The application of butyl rubber tape is straightforward; it can be cut to size, requires no special tools, and often only needs to be pressed into place. This simplicity means that homeowners can quickly address minor leaks themselves, saving both time and money on professional repairs.

The primary purpose of a wiring loom wrap is to bundle and secure the many wires that run throughout a vehicle in a neat and organized manner. This not only makes it easier for technicians to access and repair the wiring, but also helps to prevent the wires from rubbing against each other or other components, which can cause wear and damage over time.

how to use self amalgamating tape. The tape's resistance to heat, oil, and other automotive fluids makes it a reliable option for repairing minor issues in a car or truck.

Key Advantages of Butyl Rubber Roofing Sheets

3m amalgamating tape. This not only enhances the overall integrity of the filling but also helps to reduce the risk of post-operative sensitivity.

3m amalgamating tape. This not only enhances the overall integrity of the filling but also helps to reduce the risk of post-operative sensitivity.In summary, high voltage self-fusing rubber tape is a vital product that provides exceptional insulation and protection in a variety of applications. Its self-fusing capabilities, durability, and moisture resistance make it an ideal choice for electricians, engineers, and DIY enthusiasts alike. As technology continues to advance, the demand for reliable and efficient insulation solutions like self-fusing rubber tape will undoubtedly grow, reinforcing its status as an indispensable tool in electrical work. Whether you're fixing a simple wire or undertaking a complex electrical project, having high voltage self-fusing rubber tape in your toolkit can ensure safety and reliability in your work.

Applications for Butyl Rubber Sealant Tape

Butyl Rubber Tape

Characteristics of High Voltage Insulation Tape

3M rubber tapes have operating temperatures ranging from 176°F (80°C) to 221°F (105°C). Some, Linerless Rubber Splicing Tape 130C and Rubber Splicing Tape 23, have overloads temperatures up to 266°F (130°C). Because of this high heat attribute; there are many industrial settings where it is common to use rubber tape in lower voltage applications to moisture seal, pad and insulate: