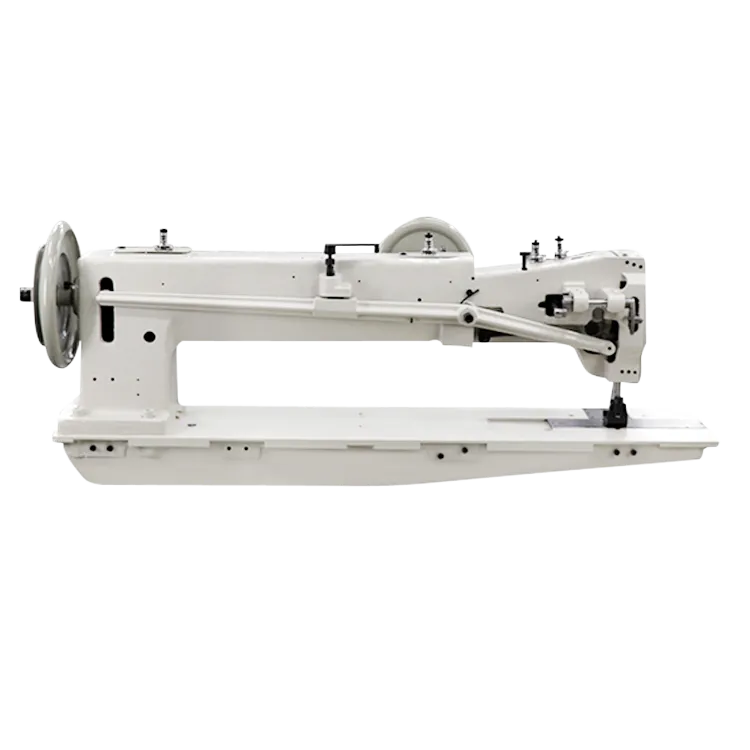

Overall, heavy duty sewing machines are built for longevity, with all-metal construction and premium internal components. They can sew for years without issues and only need periodic oiling. By contrast, plastic gears and components in standard machines wear out more quickly. Professional heavy usage requires the durable construction of true heavy duty machines.

The Art and Craft of Quilting Machine Embroidery Designs

1. Practice on Scrap Fabric Start with practice pieces before working on the final project. This approach allows one to get comfortable with the needle and thread, honing the technique without the pressure of a completed piece.

Furthermore, it features an automatic needle threader, which simplifies preparation and minimizes frustration. The included walking foot also aids in evenly feeding layers of leather, allowing for consistent stitch alignment. This focus on ease of use ensures that leatherworkers can concentrate on their creativity rather than getting bogged down by technical difficulties.

the cub leather sewing machine

1. Sturdy Build One of the most significant advantages of heavy-duty machines is their solid construction. Often made of metal rather than plastic, these machines can withstand the rigors of intensive sewing projects.

What is a Twin Needle?