Hex washer head screws come in various materials, each suited for specific applications. Stainless steel screws, for instance, offer excellent corrosion resistance and are commonly used in outdoor or marine environments Stainless steel screws, for instance, offer excellent corrosion resistance and are commonly used in outdoor or marine environments

Ease of Use and Ergonomics

For sewists working with woven fabrics, the coverstitch can create an excellent alternative to serging for seam finishes, providing a clean edge that resists fraying while allowing for some stretch. It is particularly advantageous in garment construction that involves bias-cut panels where flexibility is essential.

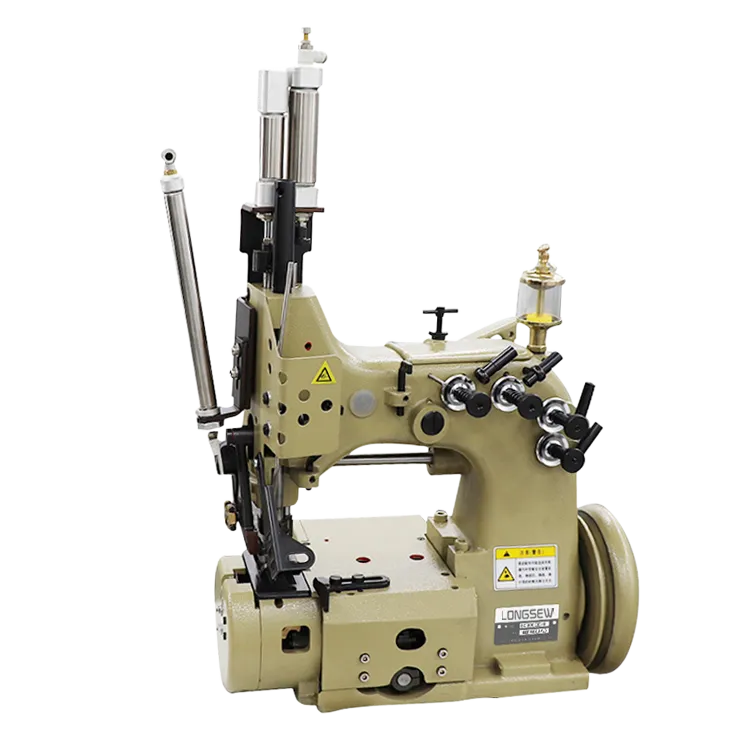

The Functionality of Gunny Bag Sewing Machines

B. Leatherwork and Accessories:

Readers will discover ideas for crafting leather bags, wallets, belts, and other accessories using thecapabilities of a heavy duty sewing machine.

The versatility of the modern chain stitch machine is evident in its applications across various sectors. In the garment industry, it is widely used for sewing stretch fabrics and intricate designs, allowing for more intricate patterns without sacrificing quality. Moreover, the machine can be customized with different needle sizes and thread types, further expanding its range of capabilities. This adaptability not only meets the demands of contemporary fashion but also supports innovative design techniques, pushing the boundaries of creative expression in textile production.

The introduction of high-speed overlock sewing machines has revolutionized production methods in the textile industry. One of the most significant benefits is productivity. With the ability to sew faster and with more precision, manufacturers can fulfill higher volume orders without compromising quality. This efficiency is particularly beneficial in today’s market, where consumer demand for trendy and affordable clothing is ever-increasing.

high speed overlock sewing machine

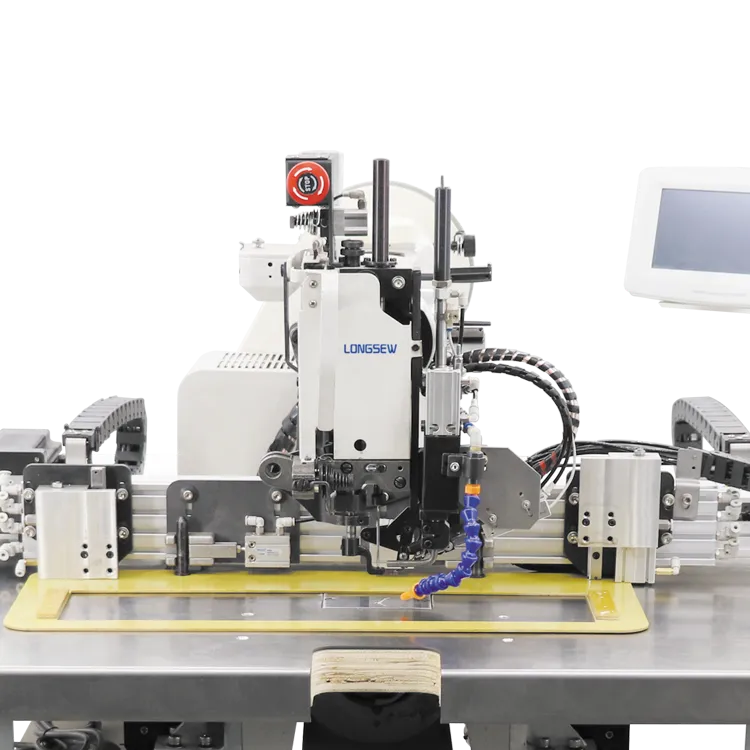

However, while automatic template sewing machines offer numerous advantages, they are not without their challenges. Initial investment costs can be high, making them less accessible for small businesses or individual crafters. Additionally, there is a learning curve associated with mastering these machines, which may deter some users. Nevertheless, as more people become accustomed to technology in their daily lives, these barriers are gradually being overcome.

Understanding Compound Feed Sewing Machines

Handheld sewing machines are known for their portability and user-friendly design. They are perfect for quick fixes, on-the-go sewing needs, and small sewing tasks. Whether you need to hem pants, repair a torn seam, or work on craft projects, a handheld sewing machine can be your trusted companion.

Enhancing Efficiency and Productivity

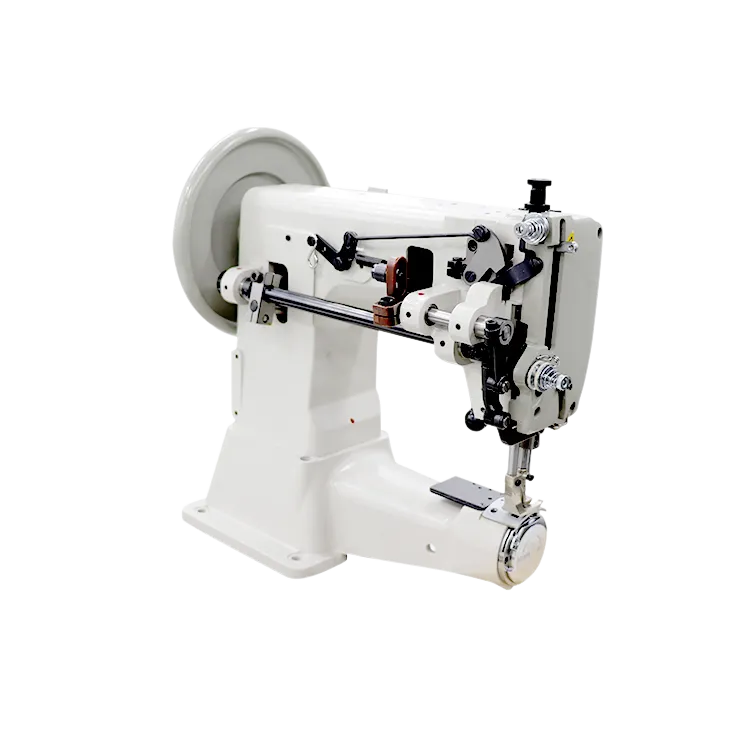

long arm sail sewing machine with puller

A PP bag silai machine is specifically designed for sewing and stitching polypropylene bags, which are commonly used for packaging agricultural products, industrial materials, and consumer goods. These machines are engineered to handle various bag designs and sizes, making them an essential tool in factories that manufacture PP bags.

Not all hand crank sewing machines are created equal; choosing the right model is crucial for successful leatherwork. Artisans should look for machines specifically designed for heavy materials, with features such as adjustable presser foot pressure and robust needle systems.

Speed

3. Sustainability As the world gravitates towards eco-friendly solutions, PP woven bags made with stitching machines offer a sustainable alternative to single-use plastic bags. These bags can be reused multiple times, thus reducing overall plastic waste.

Moreover, walking foot machines can accommodate various types of stitches and sewing techniques. For instance, industries that require decorative stitching or intricate designs benefit from the machine’s adaptability, allowing for a range of applications without the need for multiple machines. This versatility reduces equipment costs and saves valuable space on the production floor, as fewer machines are required to achieve a wider variety of sewing tasks.

industrial walking foot machine

Benefits of Using a Heavy-Duty Quilting Sewing Machine

heavy duty quilting sewing machine

Choosing a sewing machine for thick materials requires careful consideration of several factors, including motor power, presser foot options, and overall build quality. By ensuring your machine has the right features, you pave the way for successful sewing projects that involve heavy fabrics. Investing in a quality machine will not only enhance your sewing experience but also elevate the quality of your finished products. Happy sewing!

3. Depreciation Overlock machines represent a significant investment for manufacturers. Understanding the depreciation of these machines over time can help in calculating accurate production costs.

Using a double needle requires some adjustments to your sewing machine and technique. First, you need to ensure that your machine is compatible with a double needle, as not all models can accommodate this tool. Once you’ve installed the needle, you will need to use two spools of thread, one for each needle. This setup creates a beautiful twin needle stitch, giving your projects a professional finish.

In the fast-paced world of manufacturing, especially in the textile and packaging industries, efficiency and precision are key. One essential tool that has gained attention for its role in these sectors is the bag closing sewing machine head. These machines are specifically designed to seal bags securely, ensuring that products remain protected and intact during transportation and storage. Understanding the intricacies of bag closing sewing machine heads can help manufacturers optimize their operations and improve product quality.

Sewing is a creative outlet that can lead to beautiful handmade items. Whether you choose to make a tote bag, pillow cover, skirt, fabric coasters, a zippered pouch, or an apron, these easy sewing projects are not only beginner-friendly but also enjoyable. As you complete each project, you’ll gain confidence in your sewing skills and may even spark a lifelong passion for this art. So, gather your materials, set up your sewing machine, and dive into the wonderful world of sewing!

In conclusion, the hi-speed lockstitch sewing machine is a cornerstone of modern textile manufacturing. Its efficiency, consistency, and technological advancements not only boost productivity but also help address sustainability concerns. As the fashion and textile industries continue to evolve, the hi-speed lockstitch machine will undoubtedly play a critical role in shaping the future of garment production, offering opportunities for both innovation and improved operational effectiveness. Embracing this technology is essential for manufacturers aiming to thrive in an increasingly competitive marketplace.

The Double Needle Walking Foot Sewing Machine An Essential Tool for Creatives

The inclusion of features such as automatic thread cutting and tension control not only enhances precision but also reduces manual intervention, contributing to a more streamlined workflow. Furthermore, the integration of digital technology enables real-time monitoring and maintenance, allowing operators to identify and rectify issues before they lead to significant downtime. Environmental considerations have also influenced the design and functionality of these machines, with newer models emphasizing energy efficiency and the use of sustainable materials for components. As industries continue to evolve, the demand for bag closing sewing machines is set to rise, driven by the need for efficient and reliable packaging solutions.

When shopping for a sewing machine during these specials, it’s essential to know what features to look for. First, consider your sewing needs. Are you primarily interested in quilting, garment construction, or perhaps crafting home decor? Different machines cater to different sewing techniques, so it’s crucial to match the machine’s capabilities with your project requirements. For example, quilting machines are designed with larger throat spaces to accommodate bulky layers, while embroidery machines come with features enabling intricate designs and patterns.

Tips for Using a Walking Foot

1. Practice on Scrap Fabric

What is a Lockstitch Sewing Machine?

Cutting the fabric along the marked lines requires great precision. This is where the skill of the sewer comes into play. Using sharp scissors or rotary cutters, the fabric is cut carefully, making sure to follow the cutting lines exactly to avoid any discrepancies. Even a slight deviation can alter the fit and aesthetic, so attention to detail is paramount. After cutting, it is common practice to use notches and markings to indicate seam allowances, darts, and other important sewing details, further enhancing the accuracy of the garment assembly.

cutting line sewing

The zigzag stitch is another defining feature of this sewing machine. This stitch offers incredible flexibility, enabling seamstresses to create a variety of finishes and designs. It can be used to secure seams, finish raw edges, create decorative patterns, and even appliqué. The ability to adjust the width and length of the zigzag also means that sewing enthusiasts can customize stitches to suit their projects—whether that’s heavy upholstery, delicate garments, or quilting.

Heavy duty sewing machines are designed to handle thick fabrics and multiple layers, making them indispensable in industries that require robust stitching capabilities, such as upholstery, leatherworking, and manufacturing of workwear. These machines are built with superior materials and components, ensuring they can withstand the rigors of daily use. However, what truly sets them apart is the motor powering them.

3. Ease of Use Many models come with user-friendly features such as automatic stitch settings, built-in thread cutters, and adjustable walking feet, making sewing simpler and more efficient even for beginners.

Stainless steel screws, for instance, offer excellent corrosion resistance and are commonly used in outdoor or marine environments Stainless steel screws, for instance, offer excellent corrosion resistance and are commonly used in outdoor or marine environments

Stainless steel screws, for instance, offer excellent corrosion resistance and are commonly used in outdoor or marine environments Stainless steel screws, for instance, offer excellent corrosion resistance and are commonly used in outdoor or marine environments