In industrial applications, 3 8 full threaded rods are commonly used in various scenarios

Additionally, the 10% 16% self-drilling screw is designed to provide excellent holding power

Beyond its functional advantages, the Tek screw head also offers aesthetic benefits. Its flush finish when embedded in the material provides a clean, streamlined look, which is highly sought after in modern architectural designs and electronics Its flush finish when embedded in the material provides a clean, streamlined look, which is highly sought after in modern architectural designs and electronics

If you’re a sewing enthusiast or a professional tailor, you know the importance of having the right tools at your disposal. One such tool that has gained popularity in recent years is the twin needle sewing machine. As its name suggests, this machine utilizes twin needles, allowing you to create beautiful and intricate designs with ease. In this article, we will explore the benefits of twin needle sewing machines for sale and why they may be a valuable addition to your sewing arsenal.

Single needle quilting machines are essential tools for creating intricate and detailed quilting designs. These machines are great for both professional quilters and hobbyists who want to add a touch of elegance to their quilting projects. However, the price of a single needle quilting machine can vary depending on the brand, features, and overall quality.

Applications of Lock Sewing

4. Precision The advanced engineering of industrial machines allows for greater accuracy in stitching, ensuring professional quality in every seam. This precision is vital for high-end garment production and intricate sewing projects.

2. Training Skilled Labor Providing training for operators can significantly increase efficiency. Skilled workers can produce higher quality seams quicker, leading to a decrease in the overall machine rate.

Choosing the Right Pattern

Handheld Sewing Machine vs. Heavy Duty Sewing Machine: Choosing the Best Sewing Machine for Beginners

One of the most significant advantages of the speed shuttle hook is the enhancement of hand-eye coordination. Athletes can focus solely on their swing, timing, and footwork without distraction. This concentrated practice is crucial in sports where precision is paramount. For instance, in badminton, the speed at which players must react is astonishing; hence, refining their striking technique using the speed shuttle hook can lead to improved performance during matches.

Looking ahead, the future of bulk bag sewing machines looks promising. As industries continue to grow and evolve, the demand for efficient and reliable packaging solutions will only increase. Companies investing in the latest technologies, such as IoT (Internet of Things) for predictive maintenance and smart manufacturing, will likely lead the way in optimizing production processes and enhancing overall efficiency.

4. High-speed Embroidery The speed at which these machines operate is another major benefit. With the capability to produce high-quality embroidery at rapid speeds, they enable businesses to meet tight deadlines and increase overall production capacity.

two needle embroidery machine

Mastering the art of needle positioning when hand sewing leather can dramatically improve the quality of your work. By understanding your materials, selecting the right needle, maintaining correct angles, managing thread tension, and experimenting with various stitching techniques, you'll be well on your way to creating stunning leather goods. Take your time to practice and refine your skills, and remember that, like any craft, mastery comes with experience. Happy sewing!

2. SINGER Heavy Duty 4423 This machine is perfect for sewing leather thanks to its powerful motor and adjustable presser foot. It offers an array of stitch options, allowing new crafters to experiment with different designs.

An overlocker, also known as a serger, is an indispensable tool for both professional and amateur seamsters. Unlike a standard sewing machine, which primarily stitches fabric together, an overlocker is designed to finish edges and seams, giving garments a polished look while preventing fraying. With its ability to trim excess fabric as it works, an overlocker streamlines the sewing process and introduces creative possibilities. So, what can you do with an overlocker? Let’s explore various techniques and projects that highlight this versatile machine’s capabilities.

These innovations not only enhance the user experience but also improve the adaptability of the machines to various sewing tasks. With the integration of technology, manufacturers can produce more complex designs and styles that cater to changing fashion trends.

In conclusion, bag closing sewing machine heads play a vital role in modern manufacturing processes, particularly within industries focused on bagged products. Their ability to improve efficiency, ensure precision, and offer versatility makes them a valuable investment for businesses looking to enhance their operational capabilities. As technology continues to evolve, the features and performance of these machines are likely to advance, further revolutionizing the way products are packaged and sealed. Understanding the importance of these machines can help manufacturers stay competitive in an ever-changing market, ultimately leading to greater success and growth.

In today’s fast-paced industrial environment, efficiency and accuracy are paramount. One of the unsung heroes of modern packaging is the automatic bag closer machine. These machines streamline the process of sealing various types of bags, thereby enhancing productivity and minimizing labor costs. The significance of automatic bag closer machines transcends mere convenience; they are a crucial component in ensuring the quality and integrity of packaged products across diverse industries.

stitch lock.

A lockstitch sewing machine creates a stitch by interlocking a top thread and a bobbin thread. The top thread, which is fed from a spool, is threaded through a needle, while the bobbin thread is wound into a small spool that sits underneath the needle plate. As the needle penetrates the fabric, it carries the top thread down, creating a loop which the bobbin thread catches. As the needle ascends, the two threads interlock, forming a secure stitch. This simple yet effective mechanism is what makes lockstitch machines popular and indispensable in numerous sewing applications.

The importance of choosing the right upholstery machine needles cannot be overstated when it comes to achieving high-quality results in your upholstery projects. These small but essential tools play a crucial role in determining the final look and durability of your upholstery work.

4. Speed Many lockstitch machines are designed for high-speed sewing, enabling manufacturers to boost productivity. Faster sewing speeds translate to increased output, which is vital in a competitive market.

Training staff to operate CNC programmable sewing machines is relatively straightforward, which can help businesses offset some of the labor shortages currently affecting the textile industry. While skilled operators are still essential for overseeing the machines and ensuring that they are functioning properly, the requirement for advanced sewing skills is diminished as workers can be trained to manage the software and machinery within a shorter timeframe.

As the name suggests, a single stitch leather sewing machine is designed to create a single stitch per cycle, using a locking stitch mechanism that produces durable seams. Unlike multi-stitch machines, which might generate various stitch styles and patterns, the single stitch model focuses on creating a robust, reliable seam that stands up to the stresses of daily use. This is particularly important in leatherwork, where the materials often endure significant wear and tear.

- Brand Reputation Research different brands and read reviews to find reliable machines known for their durability and customer support.

The versatility of the floating foot sewing machine makes it an invaluable tool for a wide range of sewing projects. From crafting clothing to creating home décor items like cushions and curtains, this machine handles it all with ease. It's invaluable for quilters who need to sew together multiple layers without compromising the integrity of their work. Additionally, the floating foot is also effective for free-motion embroidery, allowing seamstresses to express their artistic flair.

3. Versatility Many industrial sewing machines come equipped with various attachments and features that allow for a wide range of sewing techniques. From straight stitching to zig-zag and overlock stitching, these machines can handle diverse sewing projects, making them ideal for quilters, garment makers, and craft enthusiasts.

4. Metal Construction for Durability Hi-speed lockstitch machines are typically designed with sturdy metal bodies, ensuring longevity even under constant use in busy production environments.

Cutting the fabric along the marked lines requires great precision. This is where the skill of the sewer comes into play. Using sharp scissors or rotary cutters, the fabric is cut carefully, making sure to follow the cutting lines exactly to avoid any discrepancies. Even a slight deviation can alter the fit and aesthetic, so attention to detail is paramount. After cutting, it is common practice to use notches and markings to indicate seam allowances, darts, and other important sewing details, further enhancing the accuracy of the garment assembly.

cutting line sewing

There are numerous outlets where you can find industrial leather sewing machines for sale. Online marketplaces, specialty sewing machine retailers, and industrial equipment suppliers are all excellent places to search. Additionally, consider attending trade shows or leather crafting expos where you can see machines in action and talk to knowledgeable representatives.

Additionally, FIBC sewing machines often incorporate multi-directional stitching capabilities, which enhance the bag's structural integrity. The ability to sew both straight and curved lines is particularly beneficial when creating FIBC designs that require reinforced corners or custom shapes. This versatility not only increases production efficiency but also allows manufacturers to cater to specific client requirements.

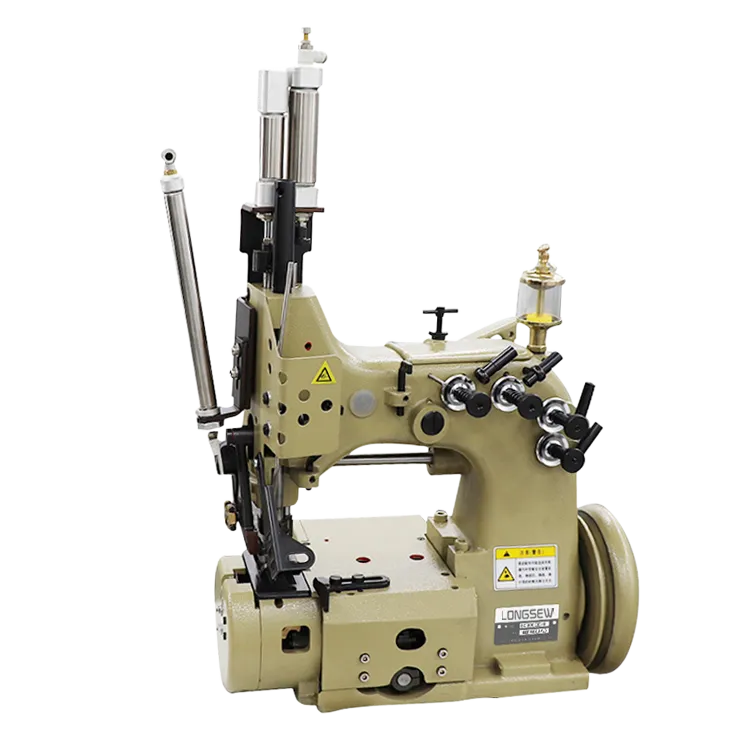

fibc sewing machine head

What Is the Best Computerized Sewing Machine to Buy?

Its flush finish when embedded in the material provides a clean, streamlined look, which is highly sought after in modern architectural designs and electronics Its flush finish when embedded in the material provides a clean, streamlined look, which is highly sought after in modern architectural designs and electronics

Its flush finish when embedded in the material provides a clean, streamlined look, which is highly sought after in modern architectural designs and electronics Its flush finish when embedded in the material provides a clean, streamlined look, which is highly sought after in modern architectural designs and electronics