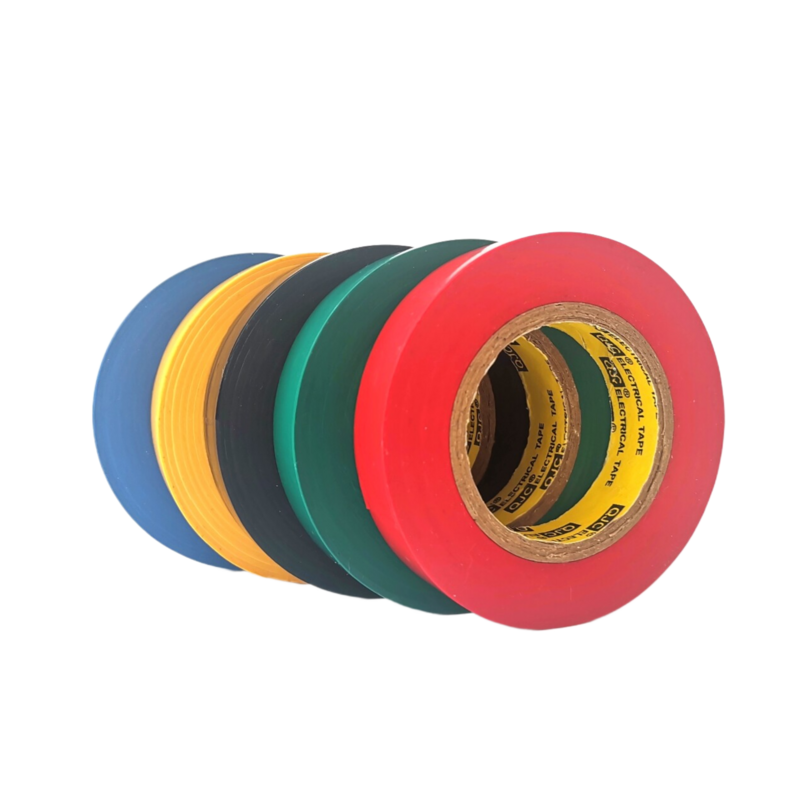

- Electrical tape is also commonly used in construction projects. Electrical tape is a type of insulating tape that is essential for securing electrical wires and connections. Electrical tape comes in various colors, with each color representing a specific purpose. Construction workers use electrical tape to insulate and protect electrical connections, secure wires, and mark circuits for easy identification. It is a crucial tool that helps ensure safety and efficiency in electrical work.

Synthetic rubber

Beyond the electrical industry, PVC insulation tape finds its use in automotive, construction, and manufacturing industries. In automotive applications, it secures wiring and protects against abrasion. In construction, it aids in sealing joints and protecting against moisture, contributing to the longevity of installations. Furthermore, it is frequently utilized in DIY projects, where it offers an easy and effective solution for various insulation and repair tasks.

In electrical applications, white PVC insulation tape is often used for insulating wires and cables. It helps to prevent electrical shorts and protects against moisture, which can lead to corrosion and system failure. Whether encasing a repair or bundling multiple wires together, this tape ensures that connections remain safe and operational.

white pvc insulation tape

Rubber tapes repel moisture and are a great solution for outdoor applications or in manholes where water may occasionally seep in.

Features of self-amalgamating tape

Construction:In the construction industry, butyl sealant tape is widely used to seal joints, seams, and gaps in various building materials, such as roofing membranes, window frames, and metal panels.

It signifies that the area is not safe for entry unless the individual is wearing appropriate personal protective equipment (PPE) and has the necessary electrical knowledge It signifies that the area is not safe for entry unless the individual is wearing appropriate personal protective equipment (PPE) and has the necessary electrical knowledge

It signifies that the area is not safe for entry unless the individual is wearing appropriate personal protective equipment (PPE) and has the necessary electrical knowledge It signifies that the area is not safe for entry unless the individual is wearing appropriate personal protective equipment (PPE) and has the necessary electrical knowledge yellow tape electrical. Similarly, in industrial plants and factories, yellow tape outlines 'live' electrical panels or identifies high-voltage areas, reinforcing the importance of electrical safety protocols.

yellow tape electrical. Similarly, in industrial plants and factories, yellow tape outlines 'live' electrical panels or identifies high-voltage areas, reinforcing the importance of electrical safety protocols.Labelling

Furthermore, butyl rubber strip exhibits excellent chemical resistance, making it suitable for use in environments where exposure to oils, acids, and solvents is common. Its ability to withstand a wide range of chemicals without degradation or loss of performance makes butyl rubber strip a valuable material for sealing and gasket applications in industrial settings.

Operating temperature range from -20°C ~ 250°C

At the heart of the problem is that even in highly bike-friendly cities like Portland, stop lights aren’t timed for the speed or cadence of the average person riding a bike. That can create unpleasant situations in traffic and even danger for cyclists—so the creators of Bike Connect set out to do something about it.

Although they may seem like simple devices, control boxes pack numerous components in that centralized box. These components include;

What advantages does rubber adhesive offer to Polyethylene Rubber Tape?