In the manufacturing sector, long tek screws find application in assembling heavy machinery and equipment

- Lastly, regional market conditions and local taxes can influence the price. In urban centers where demand is high, prices might be slightly inflated. Additionally, import duties and taxes can raise the cost of purchasing a foreign-manufactured jack hammer.

- One of the primary advantages of using fiberglass in food grade equipment is its hygienic properties. The smooth, non-porous surface of fiberglass prevents bacteria growth and is easy to clean. This feature is crucial in maintaining high standards of hygiene in the food industry, where contamination can have severe health implications.

- When it comes to performance, hex shank drill bits offer increased torque transmission, allowing for more efficient drilling with less user fatigue. Their robust design withstands heavy usage, reducing the need for frequent replacements and enhancing overall productivity.

These two sets of FRP launder systems adopted resin D411 and E fiberglass to resist the service medium and strength requirement.

They come in various designs, including step ladders, extension ladders, and platform ladders, catering to different height requirements and tasks They come in various designs, including step ladders, extension ladders, and platform ladders, catering to different height requirements and tasks

They come in various designs, including step ladders, extension ladders, and platform ladders, catering to different height requirements and tasks They come in various designs, including step ladders, extension ladders, and platform ladders, catering to different height requirements and tasks fiberglass ladder. Additionally, many models feature slip-resistant rungs, wide steps, and integrated tool trays, enhancing user comfort and convenience.

fiberglass ladder. Additionally, many models feature slip-resistant rungs, wide steps, and integrated tool trays, enhancing user comfort and convenience.

Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas

Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas drilling through rock. Moreover, the use of real-time data analysis allows operators to make adjustments on the fly, optimizing the drilling process for maximum effectiveness.

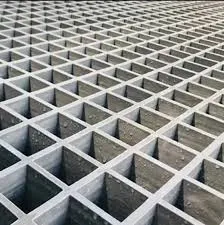

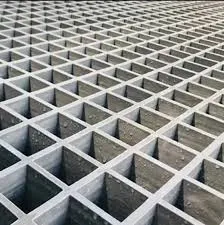

drilling through rock. Moreover, the use of real-time data analysis allows operators to make adjustments on the fly, optimizing the drilling process for maximum effectiveness.FRP Grating, baik yang terbentuk melalui proses pencetakan maupun pultrusion, menawarkan sejumlah manfaat yang signifikan dalam berbagai aplikasi industri dan komersial. Kekuatan fiberglass yang tinggi dan ketahanan terhadap korosi membuatnya ideal untuk lingkungan yang keras seperti pembangkit Listrik, area tambang dan penyulingan minyak. Kemudian, bobotnya yang ringan memudahkan dalam mobilisasi dan instalasi serta pemeliharaan, sementara permukaan yang anti-slip menjaga keamanan pengguna. Keunggulan lainnya adalah kemampuan untuk diproduksi dalam berbagai ukuran dan desain sesuai kebutuhan, meningkatkan fleksibilitas penggunaan. Dengan kombinasi kekuatan, ketahanan, dan fleksibilitas, FRP Grating menjadi pilihan yang andal dan efisien untuk berbagai keperluan struktural di industri dan sektor komersial.

This not only reduces maintenance costs but also increases the lifespan of structures, making it a cost-effective solution in the long run This not only reduces maintenance costs but also increases the lifespan of structures, making it a cost-effective solution in the long run

This not only reduces maintenance costs but also increases the lifespan of structures, making it a cost-effective solution in the long run This not only reduces maintenance costs but also increases the lifespan of structures, making it a cost-effective solution in the long run corrosion resistant fiberglass.

corrosion resistant fiberglass.