3. Regulatory Compliance Many industries are subject to safety regulations that require proper signage and markings. Utilizing red and white floor marking tape can help businesses comply with these regulations, thereby avoiding potential fines or legal issues.

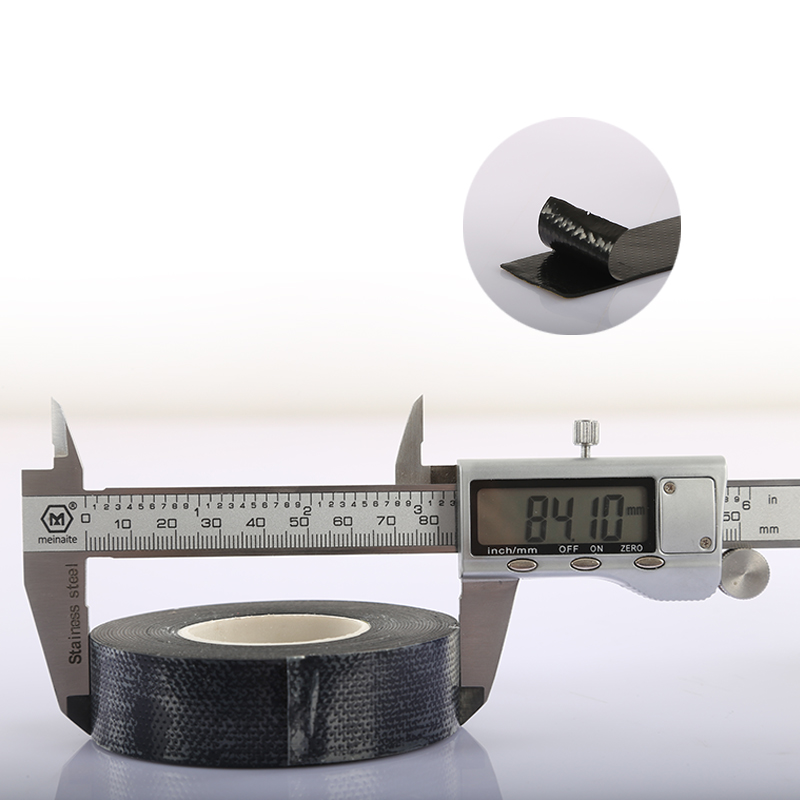

- One of the key advantages of fabric electrical tape is its durability. Unlike traditional plastic electrical tape, fabric electrical tape is made from a woven fabric material that is designed to withstand high temperatures and harsh environments. This makes it ideal for use in a variety of applications, from basic household repairs to industrial wiring projects.

Overall, amalgamating rubber tape is a valuable tool that offers a wide range of applications and benefits. Its ease of use, flexibility, and durability make it a staple in many industries and a must-have for anyone looking to achieve reliable and long-lasting seals and repairs. Whether you are a professional tradesperson or a DIY enthusiast, this versatile tape is sure to come in handy for all your bonding and sealing needs.

Key Components of a Control Box

The Complete Guide to Tape Adhesives

Edge sealant in Solar PV

cloth duct tape. From mending furniture to securing wires, fixing a leaky faucet to creating a makeshift bookmark, cloth duct tape is a reliable problem solver. It's also a favorite among campers and hikers for its lightweight yet sturdy nature, perfect for emergency repairs on gear.

cloth duct tape. From mending furniture to securing wires, fixing a leaky faucet to creating a makeshift bookmark, cloth duct tape is a reliable problem solver. It's also a favorite among campers and hikers for its lightweight yet sturdy nature, perfect for emergency repairs on gear.Control Type

Polyethylene Rubber Tape has several important characteristics:

2. Water and Chemical Resistance The silicone material is inherently resistant to moisture and various chemicals, ensuring that electrical connections remain protected even in harsh environments. This is particularly advantageous in industrial settings or during outdoor applications.

How do you apply silicone tape?

Butyl Rubber Sealant Tape: Everything a Contractor Should Know

floor marking tape black. This means that the tape can be repositioned or replaced without leaving behind any residue or damage to the floor surface. This flexibility allows for quick and efficient changes to be made to the layout of a workspace, without the need for extensive downtime.

floor marking tape black. This means that the tape can be repositioned or replaced without leaving behind any residue or damage to the floor surface. This flexibility allows for quick and efficient changes to be made to the layout of a workspace, without the need for extensive downtime.Market Trends and Availability

Its ability to form a tight seal against water ingress makes it particularly valuable in marine and offshore applications Its ability to form a tight seal against water ingress makes it particularly valuable in marine and offshore applications

Its ability to form a tight seal against water ingress makes it particularly valuable in marine and offshore applications Its ability to form a tight seal against water ingress makes it particularly valuable in marine and offshore applications 3m self amalgamating tape. Moreover, it can be used to bundle wires together, keeping them organized and safe from environmental hazards.

3m self amalgamating tape. Moreover, it can be used to bundle wires together, keeping them organized and safe from environmental hazards. Its flexibility allows it to conform to complex shapes and irregular surfaces, making it a versatile solution for a wide range of applications Its flexibility allows it to conform to complex shapes and irregular surfaces, making it a versatile solution for a wide range of applications

Its flexibility allows it to conform to complex shapes and irregular surfaces, making it a versatile solution for a wide range of applications Its flexibility allows it to conform to complex shapes and irregular surfaces, making it a versatile solution for a wide range of applications high temperature insulation tape. Moreover, it offers additional benefits like chemical resistance and flame retardancy, further enhancing its utility.

high temperature insulation tape. Moreover, it offers additional benefits like chemical resistance and flame retardancy, further enhancing its utility.In addition to being built differently than other tapes, most electrical tapes used by professionals are UL Listed, which means that they have been vigorously tested for performance when exposed to environmental elements, such as cold temperature, moisture, and sunlight. UL Listed electrical tapes are also tested for physical properties, including backing strength, elongation, and adhesive strength and must meet a high standard in order to qualify for the listing. UL Listings exist for many other types of tape – such as foil and film HVAC tapes – but each listing revolves around the specific type of tape in question. So, while your foil tape may meet UL Listing requirements for sealing rigid ducts in HVAC applications, it would not meet the code if used in an electrical application.