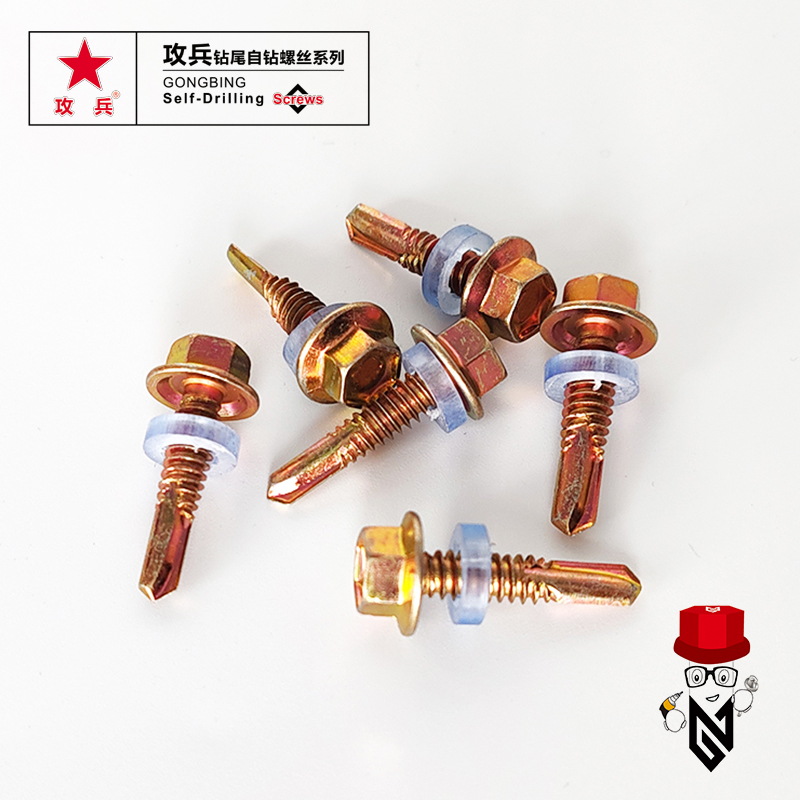

When it comes to installation, heavy-duty tek screws are relatively easy to use

4. Tighten the Screw Screw a screw or bolt into the anchor until it is tight Tighten the Screw Screw a screw or bolt into the anchor until it is tight

- 2. Natural rubberCompared with most synthetic rubber, natural rubber has good comprehensive mechanical properties, cold

- Labor costs are another important factor in the cost of spark plugs and wires. The manufacturing process involves a variety of tasks, such as casting, machining, and assembly, which require skilled workers. The cost of labor depends on factors such as the wage rate, working hours, and benefits provided by the employer.

- When choosing a high-pressure oil seal, several factors must be taken into consideration. The first is the type of fluid being sealed. Different fluids have different properties, such as viscosity and chemical reactivity, which can affect the performance of the seal. It is essential to select a seal that is compatible with the specific fluid being used.

Table 3: Features of each seal type- Furthermore, these spark plugs contribute to reduced emissions. With a more efficient burn, fewer harmful pollutants are released into the atmosphere, aligning with the growing global focus on environmental sustainability.

What are Oil Seals?

Standard 3760/3761

Oil seals are called rotary shaft seal or radial lip also.

Nitrile is the most widely used rubber (elastomer) and it’s recommended as the best for almost all standard applications. This is solely due to the fact that nitrile has some intrinsic properties, such as low cost and compatibility with most environments. Some of the general applications of nitrile are non-latex gloves, automotive transmission belts, footwear, gaskets, synthetic leather, hoses, o-rings, and oil seals.

- The elasticity and flexibility of silicone gaskets enable them to conform to irregular surfaces, creating a tight seal that prevents leaks and protects sensitive components

Operational temperature range (°C) - 4. Periodic Inspection Regularly inspect the gasket for signs of wear or damage. Replace the gasket if necessary to maintain its performance.

Material: There are several material options. Nitrile (Blank), Viton (V), Silicone (S), EPDM (E), Carboxylated Nitrile (X), HNBR (H), Polyacrylate (P), and Teflon (T).

Areas of application of this rubber are suggested by its outstanding temperature resistance (-55 °C to +200 °C), although this must not be applied to hot water or steam. Although silicone rubber almost matches NBR in oil resistance, it does not match the latter's physical and mechanical properties.

Tighten the Screw Screw a screw or bolt into the anchor until it is tight Tighten the Screw Screw a screw or bolt into the anchor until it is tight

Tighten the Screw Screw a screw or bolt into the anchor until it is tight Tighten the Screw Screw a screw or bolt into the anchor until it is tight Moreover, if contaminants enter the system, they can damage bearings, gears, and other essential components, leading to costly repairs or even complete machine failure Moreover, if contaminants enter the system, they can damage bearings, gears, and other essential components, leading to costly repairs or even complete machine failure

Moreover, if contaminants enter the system, they can damage bearings, gears, and other essential components, leading to costly repairs or even complete machine failure Moreover, if contaminants enter the system, they can damage bearings, gears, and other essential components, leading to costly repairs or even complete machine failure