In the manufacturing sector, 20-inch Tek screws find usage in heavy machinery, automotive assembly, and even aerospace engineering. They can be instrumental in fastening together large metal components, such as in the assembly of industrial equipment or vehicle chassis. Their robust design and resistance to shear forces make them a reliable choice for high-stress applications Their robust design and resistance to shear forces make them a reliable choice for high-stress applications

- One of the standout features of the Flex Tape Gray is its durability. Made with high-quality materials, this tape can withstand a significant amount of wear and tear, making it an ideal choice for projects that require long-lasting solutions. Whether you're patching a hole in your wall or securing a loose piece of furniture, the Flex Tape Gray will provide reliable support and stability.

- Brown insulation tape, a staple in the world of electrical maintenance and repair, is an essential tool for countless professionals and DIY enthusiasts alike. This humble yet robust material plays a pivotal role in ensuring safety, efficiency, and durability in various electrical applications.

Color: Black Red White Green Blue Yellow Grey

- Industrial floor marking tape also offers customization options. It comes in different colors, patterns, and thicknesses to suit specific requirements. Some tapes even have reflective properties for enhanced visibility in low-light conditions. Additionally, anti-skid variants provide extra grip, further enhancing floor safety.

- Furthermore, strong rubber waterproof tape is easy to use. Simply cut the desired length of tape, peel off the backing, and apply it to the surface you want to secure. The adhesive backing will ensure a strong and secure hold, keeping your items in place and preventing further damage.

Resistant to chemicals and solvents

Composition and Features

Remember to always do your due diligence in advance.

Not all tapes are created equal – some are better suited for high heat applications, while others are not.

Conclusion

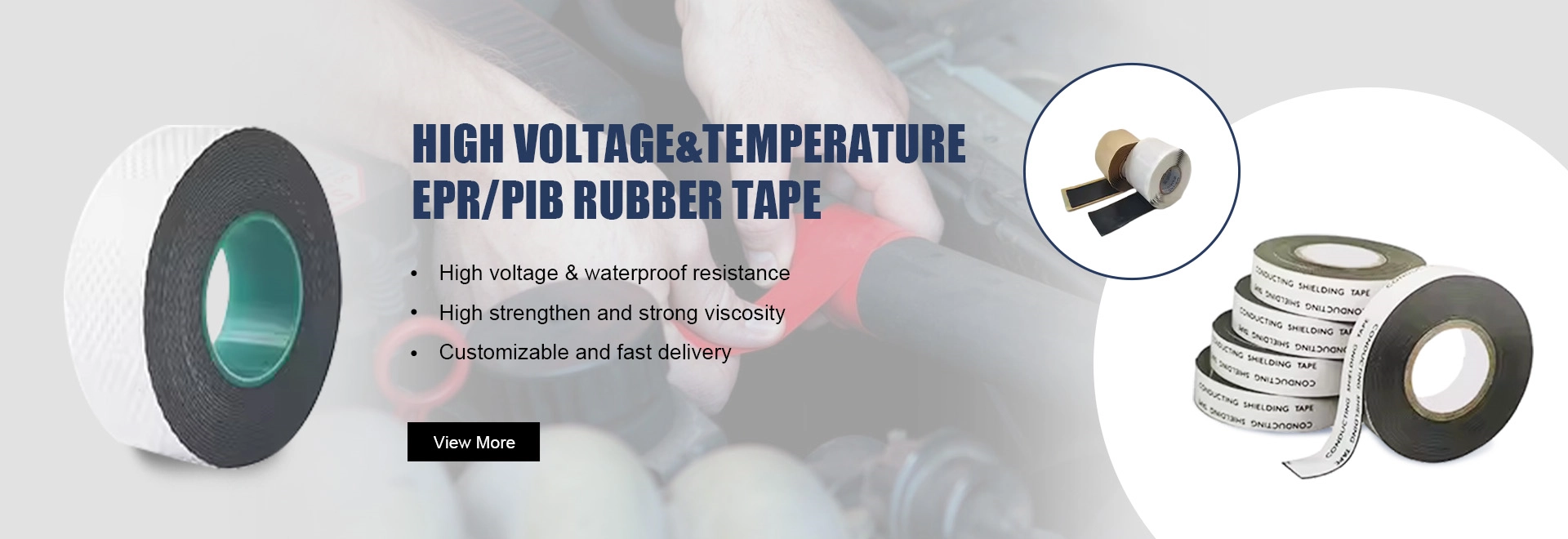

Rubber tapes are an essential component in many industries, including construction, automotive, and electrical fields. These tapes are made from different types of rubber and used for various applications, such as sealing, insulation, and packaging. Here are some of the most commonly used rubber tapes:

1. Silicone Rubber Tape: This type of rubber tape is highly resistant to heat, cold, and moisture, which makes it ideal for electrical and electronic applications. It can also be used for sealing and insulating.

2. Butyl Rubber Tape: Butyl rubber tape is known for its high adhesive strength and excellent sealing properties. It is often used in the construction industry for sealing roofs, windows, and doors.

3. EPDM Rubber Tape: EPDM (ethylene propylene diene monomer) rubber tape is highly resistant to UV radiation and weathering, which makes it ideal for outdoor applications. It is often used for sealing or protecting joints, roofs, and facades.

While price should not be the sole determining factor in selecting a supplier, it is still an important consideration. Compare pricing across different suppliers—but understand that lower prices may correlate with lower quality. Efficient distribution is another key factor. A supplier with a streamlined distribution network can ensure timely delivery, which is critical for project scheduling.

Its specific features include

Another benefit of using 3M amalgamating tape is its ease of use. Unlike traditional tapes that require scissors or other tools for cutting, this tape can be torn by hand, making it quick and convenient to apply in tight spaces or emergency situations.

Low-Density Polyethylene Film (LDPE) Mosaic Tile Tape (63502M) is a low-density, crystal-clear tape with acrylic adhesive that can temporarily hold stone, glass, and ceramic tiles during transit and installation. After you have installed the tiles, this tape releases easily without leaving any residue. Tape widths range from 3 inches (76 millimeters) to 54 inches (1,372 millimeters).

- Utility Companies To wrap and protect utility poles, transformers, and high-voltage equipment from environmental factors that could lead to electrical failures.

As described in the article “How Polyimide Tapes are Made“, tapes are composed of two distinct layers, each of which is critical to the properties of the final product. The first layer is the backing material, and whether this is polyimide film (the generic verison of DuPont’s Kapton), polyvinyl chloride (PVC), Polyethylene terephthalate (PET), or some other plastic, cloth or paper material, this layer is selected to provide half of the tape’s final properties. The other half is determined by the adhesive layer applied to this backing layer.

1. Superior Adhesion and Flexibility One of the standout features of butyl rubber tape is its strong adhesive properties. It bonds effectively to a variety of surfaces, including metal, plastic, and concrete, making it versatile for different applications. Additionally, its flexibility allows it to conform to irregular surfaces, ensuring a thorough seal even in challenging environments.

It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments

It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments insulation tape yellow. It can also be easily trimmed to size using scissors or a utility knife, allowing workers to customize the tape to fit their specific needs.

insulation tape yellow. It can also be easily trimmed to size using scissors or a utility knife, allowing workers to customize the tape to fit their specific needs. Their robust design and resistance to shear forces make them a reliable choice for high-stress applications Their robust design and resistance to shear forces make them a reliable choice for high-stress applications

Their robust design and resistance to shear forces make them a reliable choice for high-stress applications Their robust design and resistance to shear forces make them a reliable choice for high-stress applications