At its simplest, a control box is an enclosure that houses electrical components such as switches, knobs, and controls. It’s the central point from which electrical circuits are managed, distributed, and protected. Think of it as the brain of an operation where the electrical nervous system can be coordinated with precision. In industrial applications, control boxes oversee the process of heavy machinery. In a residential context, they might regulate heating and cooling systems. The primary functions of a control box include:

A control box is an advanced electrical component that allows you to keep an eye on your connected devices and manage their operations. This physical interface comes with numerous high-end components with distinct roles key amongst them being monitoring and control.

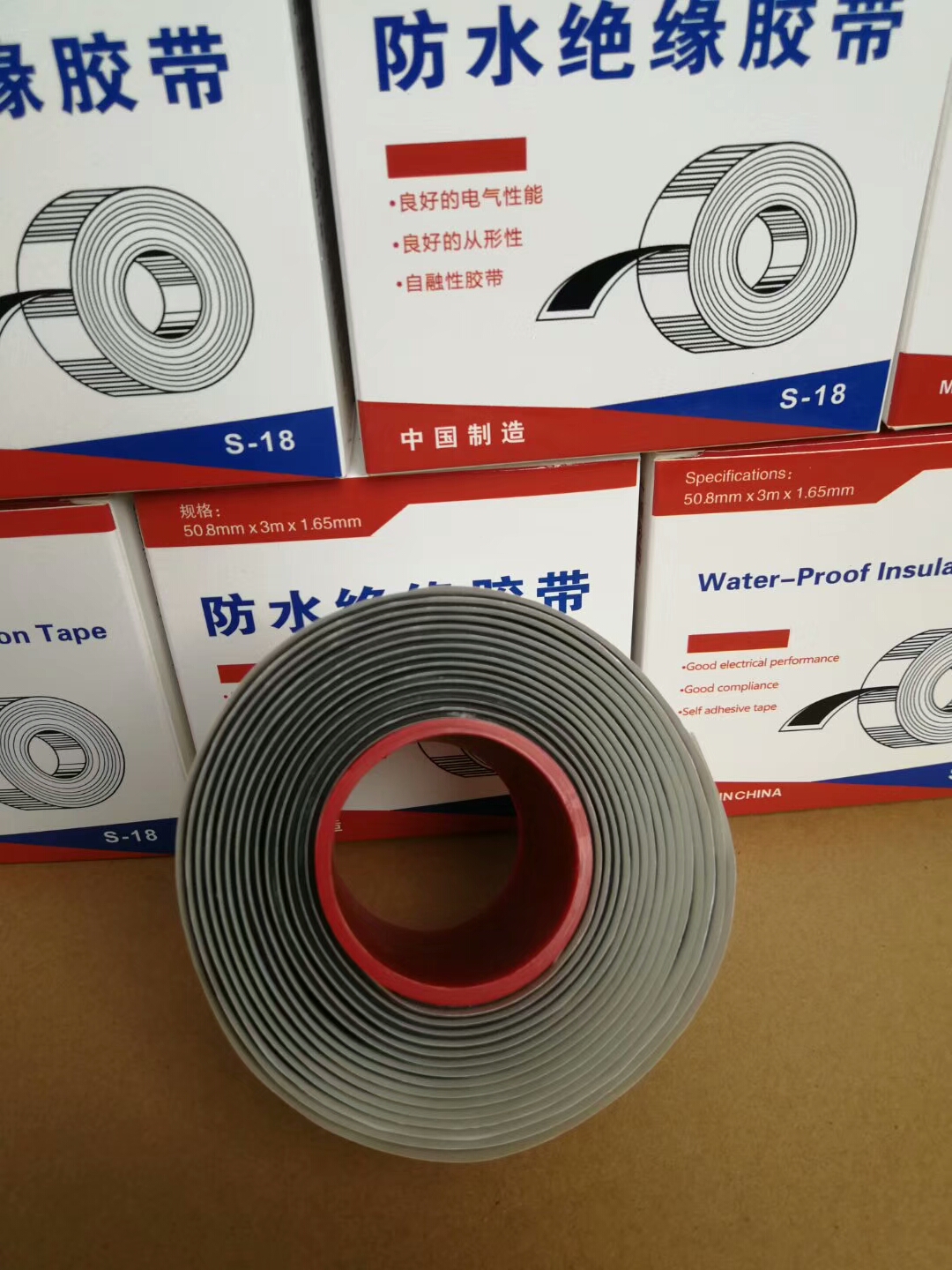

As described in the article “How Polyimide Tapes are Made“, tapes are composed of two distinct layers, each of which is critical to the properties of the final product. The first layer is the backing material, and whether this is polyimide film (the generic verison of DuPont’s Kapton), polyvinyl chloride (PVC), Polyethylene terephthalate (PET), or some other plastic, cloth or paper material, this layer is selected to provide half of the tape’s final properties. The other half is determined by the adhesive layer applied to this backing layer.

2. Durability Red insulation tape is designed to withstand high temperatures and resist various environmental factors. This durability ensures that it can maintain its insulating properties over time, even in challenging conditions.

Understanding Butyl Rubber

Splicing tape is an essential tool in the world of film production and editing. It is used to connect different pieces of film together seamlessly, allowing for smooth transitions between scenes and shots. Splicing tape comes in various types, each serving a specific purpose in the editing process.

EASE OF USE

For all intents and purposes, modified acrylics have the same characteristics as pure acrylics, but have superior adhesion to the hard-to-bond-plastics mentioned above. Generally, these are more expensive than pure acrylics and are used for plastic bonding (including vinyl and linoleum), lamination and splicing.

Remember to always do your due diligence in advance.

What is Polyethylene Tape used for?

The Advantages of Butyl Rubber Roofing Sheets

Anyone who’s left a roll of general purpose vinyl tape in the cab of their truck on a very hot summer day can attest to the fact that heat makes the adhesive soft. Extreme heat makes it ooze and flow.

insulation tape.

floor tape. From creating geometric patterns on gallery floors to defining zones in pop-up events, its transformative power is being celebrated. The tape's removable nature allows for temporary installations, making it a favorite among artists and event planners seeking a low-cost, high-impact solution.

floor tape. From creating geometric patterns on gallery floors to defining zones in pop-up events, its transformative power is being celebrated. The tape's removable nature allows for temporary installations, making it a favorite among artists and event planners seeking a low-cost, high-impact solution.5. Test the Seal Once applied, check to see if the seal is tight. You can do this by attempting to slide a piece of paper between the door or window and the frame; if it doesn’t slide out easily, your installation was successful.

rubber tape for leaks. It can be used to patch up small holes in hoses, seal around windows and doors to prevent drafts, and even serve as a temporary fix for leaky roofs. Its weatherproof nature means it can withstand various climate conditions, making it suitable for indoor and outdoor applications.

rubber tape for leaks. It can be used to patch up small holes in hoses, seal around windows and doors to prevent drafts, and even serve as a temporary fix for leaky roofs. Its weatherproof nature means it can withstand various climate conditions, making it suitable for indoor and outdoor applications.

Then, the anchor is inserted with the toggle folded closed, and the screw is tightened Then, the anchor is inserted with the toggle folded closed, and the screw is tightened

Then, the anchor is inserted with the toggle folded closed, and the screw is tightened Then, the anchor is inserted with the toggle folded closed, and the screw is tightened