In addition to their time-saving and versatility, self-drilling screws also provide a strong and secure hold

Steel wire ropes have become indispensable components across various industries, including construction, mining, maritime, and telecommunications. Among the key players in the manufacturing of steel wire ropes is China, a country that has consistently positioned itself as a global leader in the production and export of this critical material. The evolution of China's steel wire rope industry is a fascinating tale of innovation, quality, and expansion, which has profound implications for various sectors worldwide.

The versatility of iron wire mesh fencing allows it to be used in a variety of settings. In residential areas, it can serve as a stylish boundary fence while maintaining visibility, making it an excellent choice for gardens and backyards. For commercial purposes, businesses can use iron wire mesh to create secure enclosures for storage areas, parking lots, and warehouses. Agricultural settings also benefit from this fencing type as it efficiently contains livestock while allowing visibility of the fields.

Installation Costs

Dipped galvanized iron wire is a type of wire that has been coated with a layer of zinc through a process called galvanization. This process helps to protect the iron wire from corrosion and rust, making it much more durable and long-lasting in various applications.

- However, like any engineering solution, sectional water storage tanks come with their own set of considerations. Factors such as location, soil conditions, and expected water volume need to be meticulously assessed before installation. Regular inspection and cleaning are necessary to prevent contamination and ensure optimal performance.

- There are different types of chemical storage tanks available, including polyethylene tanks, fiberglass tanks, and steel tanks. Each type of tank has its own advantages and disadvantages, depending on the specific needs of the industry and the type of chemicals being stored.

In conclusion, 18-gauge wire mesh is a remarkable material that serves a wide array of purposes across multiple industries. Its strength, flexibility, and resistance to environmental factors make it an ideal choice for applications ranging from construction to security and agriculture. By understanding the characteristics and benefits of 18-gauge wire mesh, individuals and businesses can make informed decisions about its use in various projects, ultimately enhancing efficiency and sustainability.

PVC coated binding wire starts as a high-quality steel wire that is then coated with a layer of polyvinyl chloride. This coating provides several important features

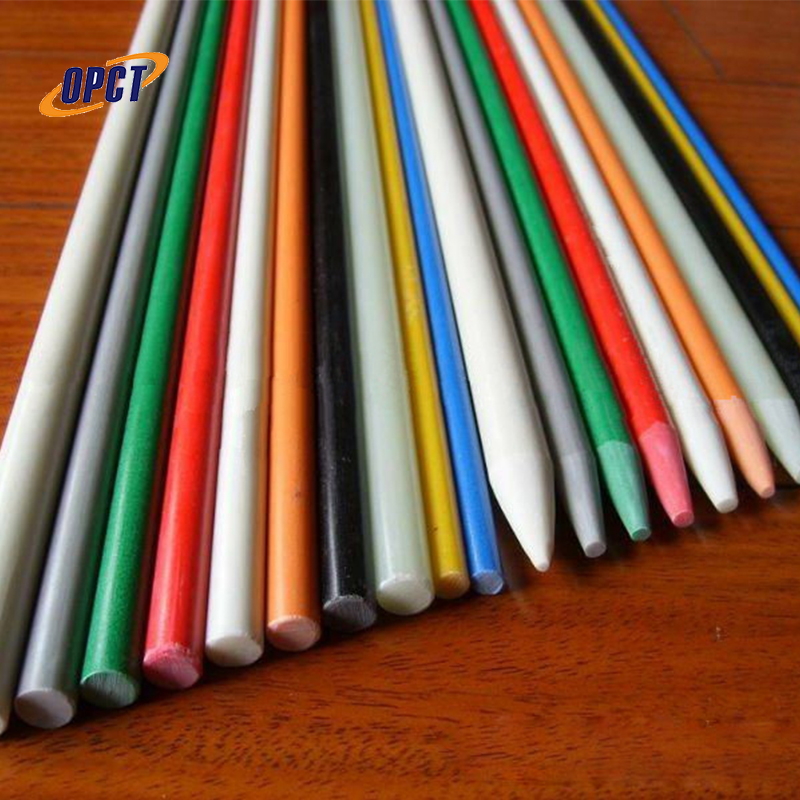

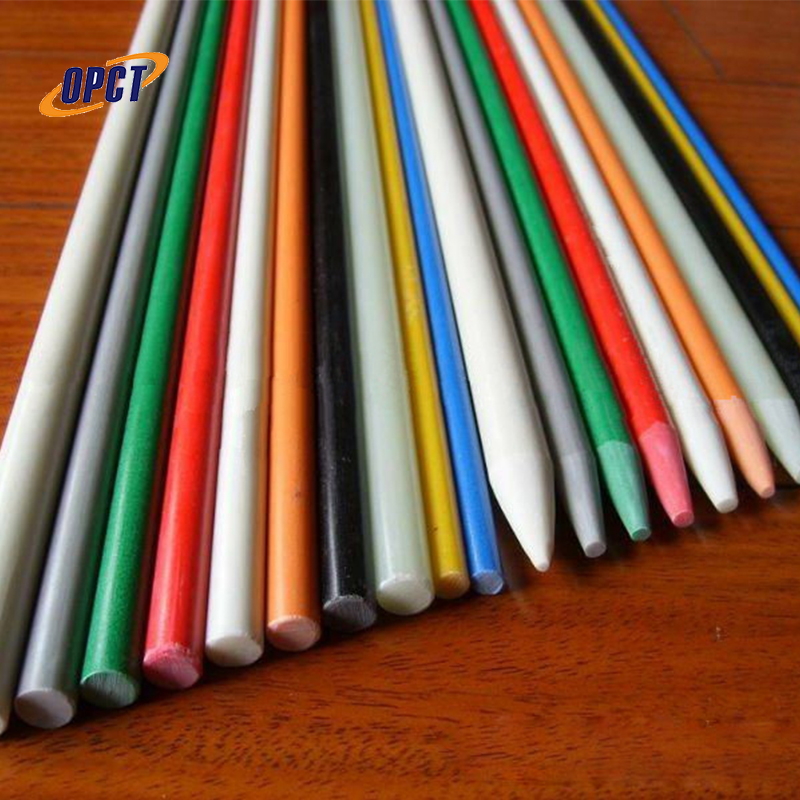

In the electrical and telecommunications fields, fiberglass rod stock serves as an essential insulating material. It is used to construct telephone poles, crossarms, and other support structures where electrical insulation is paramount. The non-conductive nature of fiberglass helps minimize risks associated with electrical hazards.

As online shopping continues to grow in popularity, the need for reliable and user-friendly price comparison websites like Pricewire will only increase. By providing consumers with the tools and information they need to make smart purchasing decisions, Pricewire is helping to make the world of online shopping more transparent and consumer-friendly.

While fiberglass septic tanks offer benefits such as lightweight installation and resistance to certain elements, it is crucial for homeowners to carefully weigh these advantages against the potential disadvantages. Issues related to durability, cost, environmental vulnerability, insulation properties, chemical sensitivity, and maintenance challenges should all be considered before making a decision. By fully understanding the drawbacks, homeowners can ensure they choose the most suitable septic tank material for their needs, ultimately contributing to the efficiency and longevity of their septic systems.

Steel water tanks are incredibly versatile, making them suitable for a wide range of applications. From municipal water supply systems to agricultural irrigation, fire protection, and even residential use, these tanks serve multiple purposes. They can be designed in various sizes and shapes to fit specific needs, whether it's a small tank for home use or a massive reservoir for industrial purposes. Their modular design allows for easy installation and expansion, catering to the dynamic requirements of growing communities or businesses.

Composition and Properties

One of the most significant benefits of a fiberglass water tank is its durability. Fiberglass is a composite material made from glass fibers and resin, which imparts exceptional strength and resistance to corrosion, rust, and chemical degradation. This makes fiberglass tanks a preferred option for storing water, especially in areas where metal tanks would succumb to rust or degradation over time. With proper maintenance, a fiberglass water tank can last for decades, making it a cost-effective investment.

● Pultruded profiles can be as much as 75% lighter than their steel counterparts without sacrificing structural strength.

Their design allows for optimal heat transfer, ensuring that the cooling process is as efficient as possible Their design allows for optimal heat transfer, ensuring that the cooling process is as efficient as possible

Their design allows for optimal heat transfer, ensuring that the cooling process is as efficient as possible Their design allows for optimal heat transfer, ensuring that the cooling process is as efficient as possible fiberglass cooling tower manufacturers. This can result in cost savings for the industries that rely on these towers for their operations.

fiberglass cooling tower manufacturers. This can result in cost savings for the industries that rely on these towers for their operations.While the initial investment for a powder coated wire mesh fence may be higher than some other fencing options, the long-term savings are undeniable. Since these fences are resistant to fading, rust, and corrosion, they require far less maintenance and replacement costs. This makes them a cost-effective choice over time, providing excellent value for property owners who aim for a balance between quality and affordability.

Fiberglass, a versatile and widely used material, is integral to various industries due to its lightweight, durability, and resistance to corrosion. Central to the manufacturing of fiberglass is the fiberglass production line, a specialized system designed to optimize production efficiency while maintaining product quality. This article explores the components, advancements, and significance of the fiberglass production line in modern manufacturing.

● The pultrusion process offers virtually endless options for customization to meet various structural and design requirements.

The advent of metal mesh sunshade technology marks a significant evolution in sustainable architecture. Factories specializing in the production of metal mesh sunshades are now at the forefront of this movement, offering solutions that blend functionality, aesthetic appeal, and environmental responsibility. As the push for energy efficiency and innovative design continues, metal mesh sunshades will remain a vital component in shaping the skylines of the future, demonstrating how advanced materials can redefine our built environment. Whether for commercial use or residential comfort, these sunshades are proving to be not only a stylish addition but also a smart investment in the world of architecture.

Cost-Effectiveness

When sourcing materials, quality is non-negotiable. Factory direct steel suppliers often have rigorous quality control measures in place. By buying straight from the factory, clients can access detailed information about the steel’s grade, specifications, and production processes. This transparency ensures that the material meets industry standards and reduces the risk of defects, which can lead to costly reworks and project delays. Additionally, many factories offer certifications, giving buyers peace of mind regarding the performance and reliability of their steel products.

Another advantage of tube fiberglass is its resistance to corrosion and rust. Unlike metal tubes, which can rust over time and degrade in quality, tube fiberglass is highly resistant to corrosion, making it a long-lasting and cost-effective option for many industries.

In various industrial applications, choosing the right piping material is crucial for ensuring durability, efficiency, and safety. Among the options available, 2-inch fiberglass pipe stands out as a robust solution that caters to a wide array of needs in sectors ranging from wastewater management to chemical transport.

Beyond livestock protection, hexagonal wire mesh is also employed in gardening and landscaping. Gardeners often use it to create supports for climbing plants such as beans, peas, and cucumbers. The mesh provides a sturdy framework for these plants to latch onto, promoting healthier growth and maximizing space in home gardens. Furthermore, it can be utilized as a protective barrier around gardens to keep out rabbits and other rodents, ensuring that crops remain intact and unharmed.

white chicken wire mesh factories. Some factories specialize in producing standard wire mesh sizes, while others are capable of customizing wire mesh to meet specific customer requirements. This flexibility allows customers to choose the perfect wire mesh for their unique needs, whether it be for a small backyard coop or a large commercial poultry farm.

white chicken wire mesh factories. Some factories specialize in producing standard wire mesh sizes, while others are capable of customizing wire mesh to meet specific customer requirements. This flexibility allows customers to choose the perfect wire mesh for their unique needs, whether it be for a small backyard coop or a large commercial poultry farm.In conclusion, coiled clout nails are more than just a simple fastener; they are an unsung hero in the construction industry. Their unique features, versatility, and efficiency make them a valuable choice for both professionals and enthusiasts alike. As the construction sector continues to evolve, the demand for reliable, durable, and sustainable materials will only grow. By embracing tools like coiled clout nails, we can ensure that our buildings stand the test of time while also taking care of our planet. So the next time you engage in a building project, consider the power of coiled clout nails—a small choice that can lead to significant impacts in construction quality and sustainability.

The finished profiles can be of virtually any cross-sectional shape (e.g., tubes, rods, I-beams, T-, U- and Z-profiles) that are either solid or hollow, then be cut to the desired length.

Understanding the Pricing of Double Twisted Black Annealed Iron Wire

Another significant benefit of iron wire mesh fencing is its environmentally friendly nature. Iron is a recyclable material, making it a sustainable choice for conscientious property owners. Fencing made from recycled iron wire requires fewer resources and energy to produce, contributing to a reduction in the carbon footprint associated with fencing materials. By choosing iron wire mesh, individuals can support eco-friendly practices while enjoying the numerous benefits it provides.

The production of blue square wire mesh involves several critical steps. Initially, high-quality steel wire is sourced, ensuring that the final product meets strength and durability standards. The wire is then subjected to a drawing process to achieve the desired thickness. Depending on the intended application, this stage might involve coating the wire with materials such as PVC or galvanizing it for rust resistance.