2. Drill the hole Use a drill bit that is slightly smaller than the diameter of the anchor rod. Drill the hole to the recommended depth, which can be found in the anchor's specifications Drill the hole to the recommended depth, which can be found in the anchor's specifications

In conclusion, a sturdy sewing machine is an invaluable asset for anyone passionate about sewing. Their durability, power, versatility, and user-friendly features make them suitable for a wide range of projects. Whether you are mending items around the house, designing fashion pieces, or crafting home décor, a sturdy sewing machine can enhance your sewing experience. By choosing a machine that embodies strength and reliability, you empower yourself to explore the full potential of your creativity, ensuring that your sewing journey is both enjoyable and fulfilling.

2. Versatility Walking foot machines can sew through a variety of materials, including regular cotton, denim, leather, and even delicate fabrics like silk. This versatility makes it a favorite among quilters, tailors, and craft enthusiasts.

The name Zig Zag derives from the machine's ability to create zigzag stitches, a significant advancement over the traditional straight stitch. This feature allows for greater versatility in sewing applications. It enables sewists to finish edges neatly, preventing fraying, and it is particularly useful when working with stretchy fabrics. This capability is invaluable for making garments that require durability and flexibility, such as t-shirts, activewear, and swimwear.

The Challenge of Thick Fabrics

Heavy-Duty Sewing Machines: A sturdy table in a home setting is usually sufficient for these machines.

Moreover, the color and pattern of the jumbo belt can significantly affect the overall outfit. A classic black or brown belt offers timeless elegance, while a bold pattern or vibrant color can serve as a focal point, drawing attention and showcasing personal style. The flexibility in styling ensures that jumbo belts can appeal to a broad audience, making them a must-have accessory in any fashion enthusiast's collection.

Modern sewing machines are designed with user convenience in mind. The automatic backstitch feature is typically easy to engage with just the push of a button or the flip of a lever. This simplicity makes sewing machines with this feature approachable for beginners who may feel intimidated by the technical aspects of sewing. The intuitive nature of these machines fosters a more enjoyable sewing experience, encouraging beginners to hone their skills without unnecessary frustration.

One of the most exciting aspects of using a Zig Zag Dressmaker Sewing Machine is the opportunity for creative expression. The variety of stitch options allow sewists to explore different techniques, from decorative edge finishes to intricate embroidery. This is particularly valuable for those looking to add unique and personal touches to their projects.

In conclusion, automotive sewing machines are vital to the automotive industry's manufacturing landscape. Their evolution has paralleled advancements in material science and consumer preferences, enabling manufacturers to produce high-quality, aesthetically pleasing interiors that meet the demands of modern consumers. As the industry continues to innovate, these machines will undoubtedly remain at the heart of vehicle interior production, shaping the future of automotive design and manufacturing.

- Overall, an automatic bag closer sewing machine is an essential tool for businesses that rely on efficient and reliable bag packaging solutions. With its speed, versatility, ease of use, and durability, this machine offers a cost-effective and efficient way to close bags securely and ensure the safe transport and storage of goods. Whether you are a farmer, manufacturer, or distributor, investing in an automatic bag closer sewing machine can help streamline your packaging process and improve your bottom line.

Applications of Chain Stitch

4. Ease of Use While it may seem complex, many modern sewing machines come with built-in coverstitch capabilities or attachments that simplify the process. Once you've mastered the technique, setting up and using a double needle coverstitch becomes a straightforward task.

Whether you are a seasoned seamstress or a beginner looking to expand your horizons, there is a sewing machine special for everyone. For those who prioritize speed and efficiency, the Brother CS6000i Computerized Sewing Machine is a top choice. With features such as an automatic needle threader and a wide table for quilting and other large projects, this machine is perfect for those who demand precision and quality in their creations.

Outerwear production involves making clothes like jackets, trench coats, parkas, and winter vests meant to be worn outside. These clothes are often made of more robust, durable materials to protect the wearer from the weather. A heavy-duty sewing machine is needed to make these clothes because it can handle thick or multiple layers and ensure the seams are strong and uniform.

4. Automation Features With advancements in technology, many baffle sewing machines now come equipped with automated features. These can include programmable settings that streamline the sewing process, reduce manual errors, and increase overall productivity.

What is a Double Needle Coverstitch?

In conclusion, automatic computerized sewing machines represent a significant advancement in the world of sewing. By merging technology with creativity, these machines have transformed the crafting experience, making it more efficient, precise, and accessible to all. As innovations continue to evolve, the future of sewing looks promising, with endless possibilities for both seasoned professionals and aspiring crafters alike. With the right tools at their disposal, anyone can embark on a journey of creativity and self-expression through the art of sewing.

Key Features of Heavy-Duty Quilting Sewing Machines

The Evolution of Leather Sewing Machines

Advantages of Using Two Needle Embroidery Machines

Battery Life:

When it comes to sewing, one of the most fundamental techniques employed by sewing machines is the lock stitch. This method is integral to creating strong, reliable seams in a wide range of textiles. Whether you are a novice in the world of sewing or a seasoned tailor, grasping the concept of a lock stitch can significantly enhance your sewing skills and understanding of machine operation.

Stitch machine embroidery designs have revolutionized the way we customize fabrics and garments. These intricate designs are created using automated embroidery machines that can stitch out complex patterns with precision and speed. From intricate floral motifs to bold typography, stitch machine embroidery designs have endless possibilities for creative expression.

Bag seaming machines are indispensable to various industries, providing efficient, reliable sealing solutions. By ensuring that products are securely packaged, these machines not only facilitate smooth operations but also help maintain the quality and safety of goods throughout the supply chain. As technology advances, we can expect further innovations in bag seaming processes, making them even more efficient and adaptable to changing industry needs. Investing in the right bag seaming machine is, therefore, a strategic move for any manufacturer aiming for success in today's competitive market.

What is a Double Needle Coverstitch?

I. Understanding Heavy Duty Sewing Machines

sewing cnc machine.

4. Type of Machine While the focus here is on single needle sewing machines, it’s important to consider that there are specialized models within this category. For instance, heavy-duty machines designed to handle thicker fabrics or those equipped for quilting purposes may come at a premium compared to standard models. Understanding the specific type of sewing you intend to do can guide you toward the right machine.

single needle machine price

The Mechanics of Long Arm Sewing

Another important thing to consider is the speed control. It is a good idea to set the speed on your own pace. In this way, you do not have to stop and re-adjust the fabric after a few seconds. When the speed is quite important for you, then you should get the variable speed control machine. That means that you can determine the speed of sewing depending on the material you are working on.

Another important thing to consider is the speed control. It is a good idea to set the speed on your own pace. In this way, you do not have to stop and re-adjust the fabric after a few seconds. When the speed is quite important for you, then you should get the variable speed control machine. That means that you can determine the speed of sewing depending on the material you are working on.

5. Precision Control Industrial long arm sewing machines often feature advanced technology that allows for precise stitching, ensuring high-quality results. This control is crucial for professional projects where the stitch quality can make or break the final product.

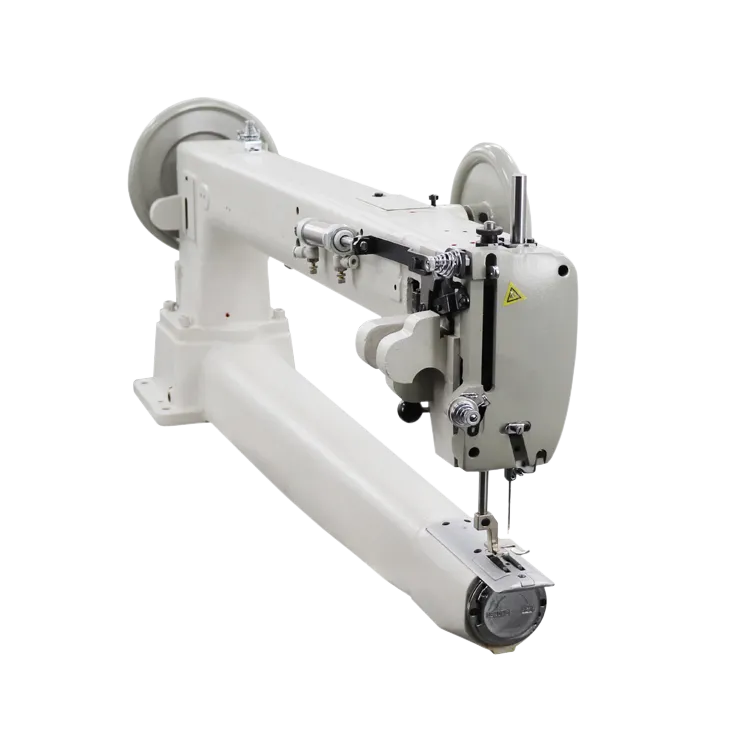

industrial long arm sewing machine for sale

The Versatile Zigzag Foot Sewing Machine A Seamstress's Best Friend

1. Custom Stitch Programming One of the most appealing features of programmable pattern sewing machines is the ability to create custom stitches. Users can design unique patterns and save them in the machine's memory for future use. This flexibility not only enhances creativity but also saves time, as users don’t have to replicate intricate designs manually each time.

lock stitch sewing machine needle.

In the ever-evolving world of textile and fashion industries, precision and efficiency are paramount. One of the modern innovations that cater to these demands is the double needle sewing machine. This versatile tool has gained popularity among professionals and hobbyists alike due to its ability to produce high-quality stitches and streamline the sewing process.

Drill the hole to the recommended depth, which can be found in the anchor's specifications Drill the hole to the recommended depth, which can be found in the anchor's specifications

Drill the hole to the recommended depth, which can be found in the anchor's specifications Drill the hole to the recommended depth, which can be found in the anchor's specifications