- In recent years, advancements in technology have led to the development of new and improved mining drill bits. These include hybrid drill bits that combine the advantages of different types of drill bits, as well as smart drill bits that incorporate sensors and monitoring devices to optimize drilling performance. These innovations have led to increased efficiency and productivity in mining operations.

AOC Aliancys announced: AOC Aliancys (Nanjing, China) started to produce the AOC resins according to the formula imported from the headquarter in the U.S.A.

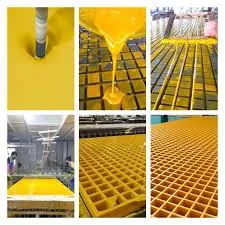

- FRP, or Fiberglass Reinforced Plastics, is a composite material made by combining plastic resins with reinforcing fibers, typically glass fibers. The result is a strong, lightweight, and resilient substance that can withstand harsh weather conditions, heavy usage, and even vandalism, ensuring longevity and low maintenance costs.

- To sum up, fiberglass pipe insulation fittings stand out as a testament to the advancements in industrial insulation technology. By providing superior thermal efficiency, longevity, ease of installation, and attractive finishes, they set a high standard for the protection and enhancement of piping systems. Whether facing the challenges of energy conservation, safety requirements, or aesthetic concerns, these fittings offer a reliable solution that pays dividends in both operational effectiveness and economical sustainability.

- One of the key advantages of using button bits for rock drilling is their ability to maintain their sharpness and cutting performance over an extended period of time. This is due to the hardness and wear resistance of the tungsten carbide buttons, which helps to minimize the need for frequent bit changes and maintenance.

- The origins of rock drills can be traced back to the late 19th century when steam-powered drills were first introduced. Today, the industry has evolved significantly, driven by advancements in technology and a relentless pursuit of innovation. Companies like Atlas Copco, Sandvik, and Ingersoll Rand are at the forefront of this evolution, each with their own unique contributions to the field.

1 inch drill bit. Be it hanging pictures, installing shelves, or setting up a new lighting fixture, this drill bit size offers the right balance of functionality and control. It allows users to drill holes with accuracy, ensuring that fixtures sit flush against walls or surfaces.

1 inch drill bit. Be it hanging pictures, installing shelves, or setting up a new lighting fixture, this drill bit size offers the right balance of functionality and control. It allows users to drill holes with accuracy, ensuring that fixtures sit flush against walls or surfaces.Durable

Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces

Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces small air jack hammer.

small air jack hammer.Support and Stability

Molded Fiberglass Grating Panels are equally strong in both directions

Meniscus Top: The concave surface, or half-moon cross-section has no grit. This molded meniscus top grating provides superior slip-resistant footing in most environments including wet or oily conditions and is the standard surface for all Specialty Steel’s molded gratings.

Meniscus Top: The concave surface, or half-moon cross-section has no grit. This molded meniscus top grating provides superior slip-resistant footing in most environments including wet or oily conditions and is the standard surface for all Specialty Steel’s molded gratings.

2.Conductive fiberglass grating

Fibergalss grating itself is an insulator, non conductive, non thermal conductivity, but in some specific places, it also has a conductive requirements. The detailed operation method is to eliminate the damage of static charge inoculation in the rock layer with a thickness of about 3~5mm. The conductive grating also has same characteristics with traditional glass steel grille ,such as corrosion resistance, flame retardant,anti strike, skid resistance, light weight and practical in refinery and armaments manufacturing factory, high-tech industry, computer room, chemical plants, dry areas and underground mining operations.

This information is essential for traversing and manipulating the data structure This information is essential for traversing and manipulating the data structure

This information is essential for traversing and manipulating the data structure This information is essential for traversing and manipulating the data structure anchor bar bits. Similarly, in algorithms like sorting and searching, anchor bar bits can be employed to mark specific positions or states, guiding the program's execution and improving its overall performance.

anchor bar bits. Similarly, in algorithms like sorting and searching, anchor bar bits can be employed to mark specific positions or states, guiding the program's execution and improving its overall performance. cemented carbide button bits. These bits can be used in a wide range of drilling applications, including oil and gas exploration, mining, geothermal drilling, and civil engineering projects. Their durability and performance make them suitable for both surface and underground drilling operations, making them a versatile solution for any drilling project.

cemented carbide button bits. These bits can be used in a wide range of drilling applications, including oil and gas exploration, mining, geothermal drilling, and civil engineering projects. Their durability and performance make them suitable for both surface and underground drilling operations, making them a versatile solution for any drilling project.Inspired by the flexibility and rigidity of natural spider silks webs, a research team led by Prof. YU Shuhong from the University of Science and Technology of China (USTC) developed a simple and general method to fabricate superelastic and fatigue resistant hard carbon aerogels with nanofibrous network structure by using resorcinol-formaldehyde resin as a hard carbon source.