In addition to providing structural support, bracing steel also plays a key role in the overall design and aesthetics of a building

T3-T8 - In conclusion, the aluminium window frame section is more than just a structural element; it is a testament to the harmonious integration of form, function, and sustainability in contemporary building design. Its robustness, versatility, and energy-saving properties make it a standout choice for homeowners and builders. Whether it's a modern high-rise or a traditional cottage, aluminium window frame sections promise to elevate both the look and performance of any building they grace.

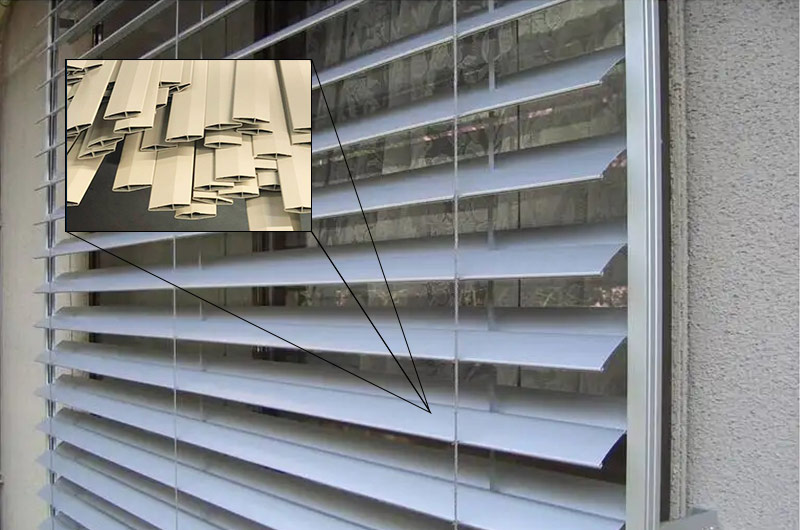

The profile is bent with both hands, and the twisting strength is good, and it can be restored after loosening your hands. If the strength of the aluminium profile is not enough, it is easy to be deformed, which may result in unqualified wind pressure resistance level, the finished switch is not smooth, and the deformation amount is too large.

Aluminum profiles fall into this category because they primarily perform the function of providing support for buildings. You can come up with virtually any type of building component in your mind and aluminum profiles might have a use for them. Though the material is heavily lacking in hardness, it does measure high in machinability. This allows production facilities to transform aluminum profiles to a great extent.

Excellent for welded parts and assemblies

One of the most striking characteristics of okrasná liatina is its ability to marry form with function

. Artisans can create a myriad of intricate patterns and reliefs that can range from delicate floral motifs to bold geometric designs. The adaptability of cast iron allows it to be molded into virtually any shape, making it an ideal choice for decorative projects. The beauty of this material lies not only in its visual aspects but also in its tactile qualities; the cool touch of cast iron complements its visual weight, providing a sense of grounding.Repurposing Within the Home or Garden

Unmatched Durability

Throughout history, numerous architectural masterpieces have showcased the elegance of okrasná liatina. From the ornate facades of historic buildings to the graceful arches of iron bridges, decorative cast iron has made its mark in urban landscapes. Each piece tells a story, reflecting the craftsmanship and artistic vision of its maker. Notable examples include the intricate balconies of French Quarter buildings in New Orleans and the grand gates of palaces and gardens across Europe. These elements enrich the cultural heritage of their locales, drawing visitors and locals alike into their charm.

Ingot casting: The process involves the ingredients, melting, casting, and homogenization of the aluminum billet.

Metal fence posts break down into two categories based on the method used for affixing them to the ground. Platted posts, for example, are the preferred option for protecting pools surrounded by a solid surface such as concrete. These posts have a steel plate welded to their bottom, and it is this plate that is then anchored using four durable bolts.

After weighing the factors like aesthetic appeal, cost considerations, durability, security, and maintenance, it’s clear that wrought iron fencing rises to the top. It offers unparalleled beauty, stands the test of time, and brings a level of security that few other materials can match.

Cost Considerations

aluminium cill profile. This means that aluminium profiles will not deteriorate over time and will continue to look great for years to come.

Understanding Sliding Door Wheels

ITEM #1 – RUST PROTECTION SPECIFICS

All these make it an ideal anodizing option to consider for aluminum profiles for windows and doors.

True wrought iron fences are hand-shaped by blacksmiths or master craftsmen. They take time to produce and are usually custom created as needed, made to order.

Surface Treatment

Aluminium window design options are virtually unlimited; there are only a few factors affecting types of aluminium windows:

Both cast iron and wrought iron are susceptible to corrosion over time when their bare surfaces are exposed to the elements. That’s why both materials will require finishing and regular maintenance. However, cast iron generally rusts more slowly than wrought iron and thus can go longer intervals between upkeep.