This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern

This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern 11kv insulation tape. The tape is designed to maintain its performance and adhesion even in challenging conditions, ensuring long-term reliability and protection for the electrical components it is used to insulate.

11kv insulation tape. The tape is designed to maintain its performance and adhesion even in challenging conditions, ensuring long-term reliability and protection for the electrical components it is used to insulate. flex tape white 4 x 5. It's compact enough to store conveniently yet large enough to cover substantial damages effectively. Whether you're dealing with a small crack or a larger repair job, Flex Tape White offers the perfect balance between coverage and precision.

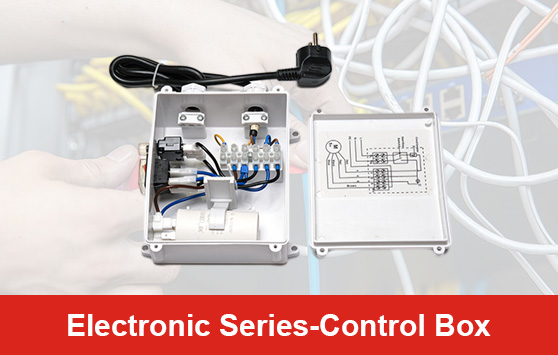

flex tape white 4 x 5. It's compact enough to store conveniently yet large enough to cover substantial damages effectively. Whether you're dealing with a small crack or a larger repair job, Flex Tape White offers the perfect balance between coverage and precision.Key Components of a Control Box

For applications that require a higher level of water resistance or waterproofing, specialized tapes or additional measures may be necessary. It’s recommended to assess the specific requirements of your application and consider the expected level of water exposure to determine whether polyethylene tape alone provides sufficient water resistance or if additional waterproofing measures are necessary.

Press and Seal: After wrapping, firmly press the tape against itself to create a strong bond. It will self-fuse, ensuring a tight and secure seal.

FAQS

Features and Benefits

The well pumps that provide water to private well systems are another area in which you’ll frequently find control boxes. Typically, these designs are relatively simple—but, like all control boxes, they serve a critically important purpose.

diall self fusing tape. Its high dielectric strength makes it safe to use on electrical components, providing an extra layer of protection against shorts and sparks. The flexibility of the tape allows for easy wrapping around irregular shapes and surfaces.

Its robust waterproofing properties make it a go-to choice for both indoor and outdoor applications Its robust waterproofing properties make it a go-to choice for both indoor and outdoor applications

Its robust waterproofing properties make it a go-to choice for both indoor and outdoor applications Its robust waterproofing properties make it a go-to choice for both indoor and outdoor applications flex tape waterproof clear.

flex tape waterproof clear.What is Heat Tape?

CONTROL BOX DESIGN

As a result of the design process, a control panel must meet functional criteria, commercial parameters, and relevant legislation.

5. Nitrile Rubber Tape: Nitrile rubber tape is commonly used in the oil and gas industry for sealing and insulating. It is resistant to oil, fuel, and other chemicals, which makes it ideal for use in harsh environments.

Overall, rubber tapes are essential for a wide range of applications in various industries. They are durable, flexible, and highly resistant to weathering and chemicals. With their unique properties and ability to adhere to a variety of surfaces, rubber tapes are a go-to solution for sealing and insulating needs.