In addition to their ease of installation, wedge anchor bolts are also incredibly strong and durable. Once properly installed, they provide a secure connection that can withstand heavy loads and high levels of stress. This reliability makes them a popular choice for a wide range of applications, from securing machinery and equipment to anchoring structural elements in buildings

If you are a fan of vintage styles and classic designs, the Singer Tradition Sewing Machine is a great option. With its timeless look and durable construction, this machine is a reliable choice for those who value tradition and nostalgia in their sewing equipment. And with special deals and discounts available, there has never been a better time to invest in this classic machine.

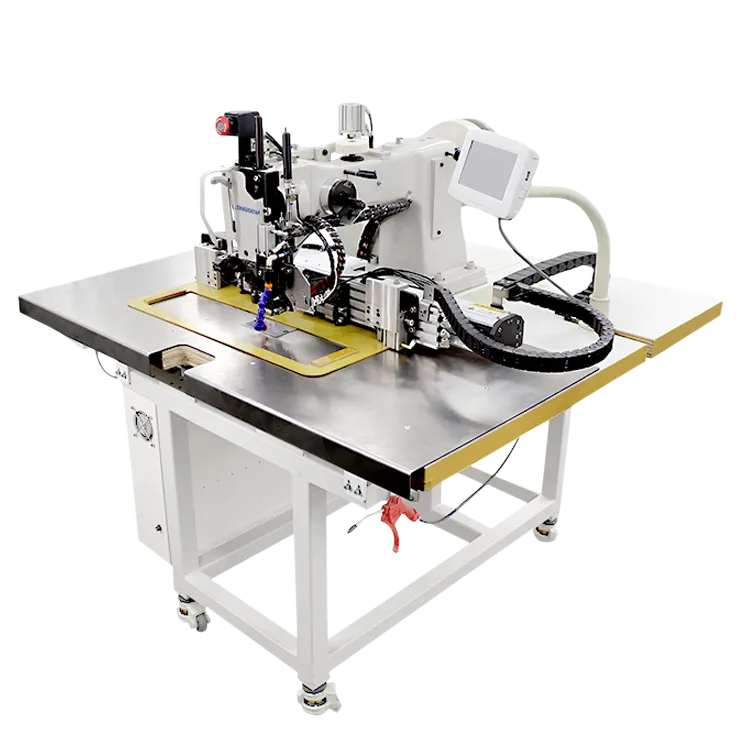

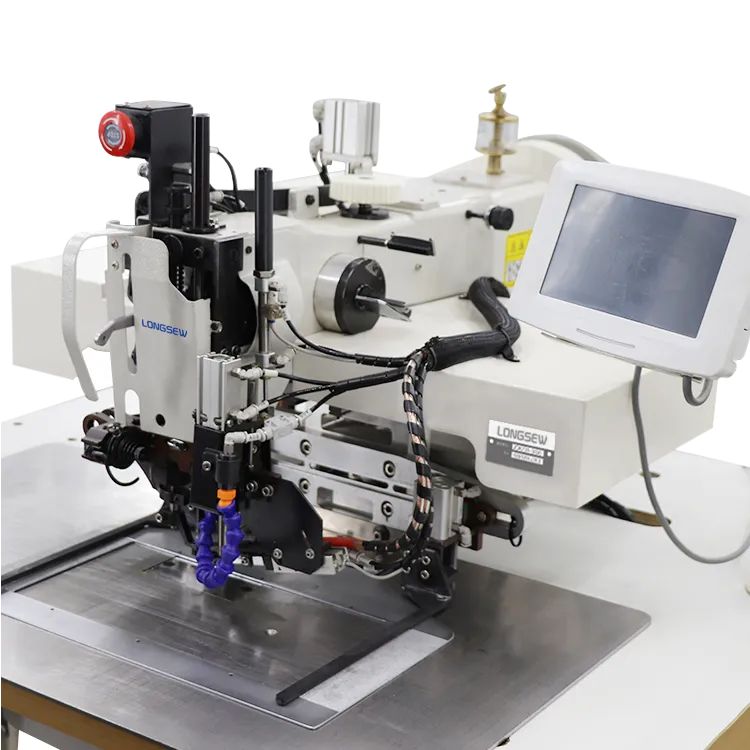

sewing machine specials

2. Improved Load Capacity With the added strength of lock stitches, jumbo bags can handle greater loads without compromising integrity. This means manufacturers can safely transport larger quantities of materials, improving efficiency in logistics and reducing transportation costs.

Type

The Cost of Zigzag Sewing Machines An Overview

5. Variety of Applications From garment construction to quilting and crafts, lock stitching can be used in a variety of applications, enhancing its utility in the sewing world.

Machines with advanced features such as automatic thread trimming, programmable stitch patterns, and digital displays will typically cost more than basic models Machines with advanced features such as automatic thread trimming, programmable stitch patterns, and digital displays will typically cost more than basic models

Machines with advanced features such as automatic thread trimming, programmable stitch patterns, and digital displays will typically cost more than basic models Machines with advanced features such as automatic thread trimming, programmable stitch patterns, and digital displays will typically cost more than basic models