Another benefit of self-drilling screws is their versatility

3. Sheet Metal Applications The self-tapping feature is especially valuable in securing sheets of metal in construction and HVAC systems.

Generally, oil seals vary in materials and types based on the corresponding application. Common materials include:

Figure 2: Typically shaped oil seal and component nomenclature

- Cracks or swelling of the component due to extreme temperatures, causing premature deterioration of the oil seal material.

Also, Viton has the widest range of resistance to chemicals. It’s resistant to several chemicals like silicone oil & grease, mineral & vegetable oil, aliphatic, chlorinated hydrocarbons, methanol fuels, and so many more.

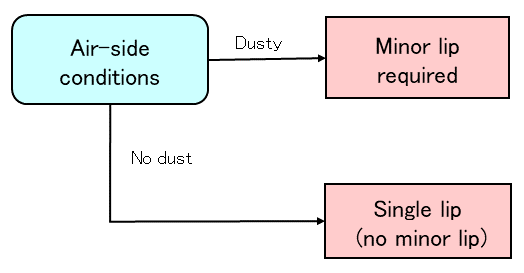

These seals are designed to fit snugly around the shaft of the machine, preventing oil from leaking out while also keeping dirt, dust, and other contaminants from entering.

- 6. Install the new cylinder head gasket.

The seal is usually made of high-quality materials such as rubber or synthetic compounds that can withstand high temperatures and pressures. It is designed to maintain a tight seal even under extreme conditions, such as rapid changes in temperature and pressure during engine operation.

Is the seal you need not available from one of our standard ranges? No problem. We design and supply seals in any material, size and quantity - from very small to very large volumes.

nbr oil seal. They come in various shapes and sizes, from O-rings to complex custom designs, allowing them to be tailored for specific applications. This versatility means NBR seals can be found securing gearboxes in wind turbines or maintaining the pressure in hydraulic cylinders on construction sites.

nbr oil seal. They come in various shapes and sizes, from O-rings to complex custom designs, allowing them to be tailored for specific applications. This versatility means NBR seals can be found securing gearboxes in wind turbines or maintaining the pressure in hydraulic cylinders on construction sites.Want to learn more? Read “Oil Seals 101, Part 2”.

Metal case