Manholes as we know them today have been in use since the mid-19th century but have evolved over time for increased safety and functionality. While they were originally built with bricks, manholes are most often built using concrete today, though some are made of plastic, fiberglass or a similar composite. Composite liners are more likely to be used in regions with a high risk of corrosion or in areas where exfiltration or infiltration into the line is common. Many manholes today are built aboveground first. These are typically referred to as precast manholes—designed to fit a dug-out space and assembled on site before being lowered into the ground.

Moreover, these covers can be customized in terms of size, shape, and color to match the aesthetic of the surrounding area. This customization allows for seamless integration into the environment, whether it’s a sleek design for a modern commercial building or a more rustic appearance for a garden pathway.

Furthermore, the round design is optimal for distribution of stress. When vehicles pass over a manhole cover, the weight is typically distributed evenly across the surface due to its symmetrical shape. This characteristic reduces the likelihood of cracking or breaking under heavy loads, leading to increased durability. With the urban environment constantly evolving, where heavy vehicles and machinery are commonplace, the robustness of round covers becomes even more significant.

As urbanization continues to transform cities around the world, the integration of nature into the urban environment has become increasingly important. One effective solution to facilitate this integration is the use of concrete tree grates. These functional yet aesthetic elements serve multiple purposes, benefiting both urban infrastructure and the ecosystem.

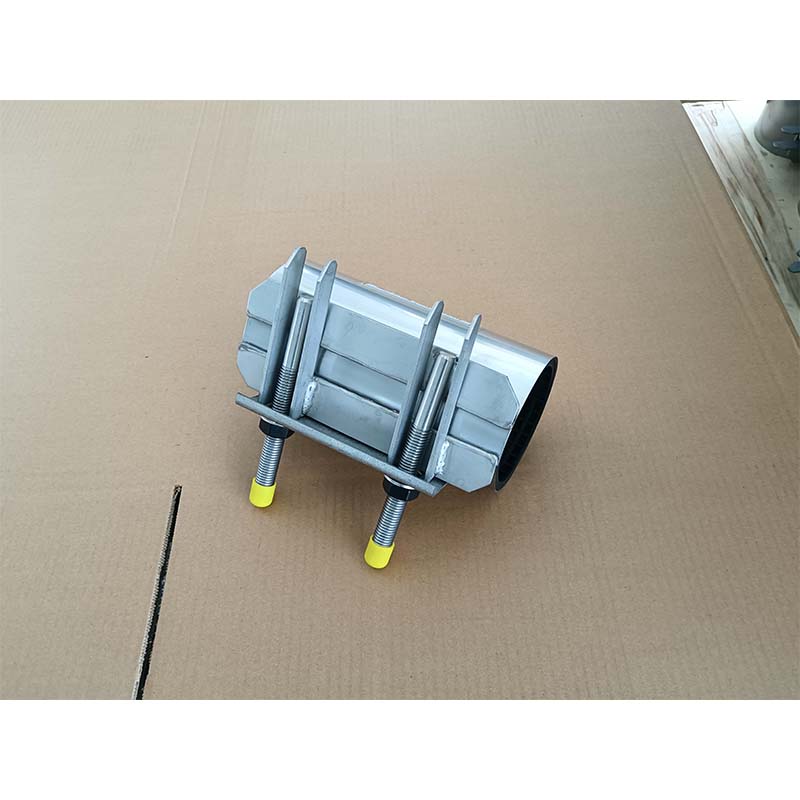

5. Check for Leaks After securing the clamp, turn the water supply back on and monitor the repair site for any remaining leaks. If everything appears secure, you have successfully used the repair clamp.