One significant advantage of butterfly bolts over traditional screws or anchors is their exceptional holding power

However, it's important to note that the self-drilling screw is not without its challenges

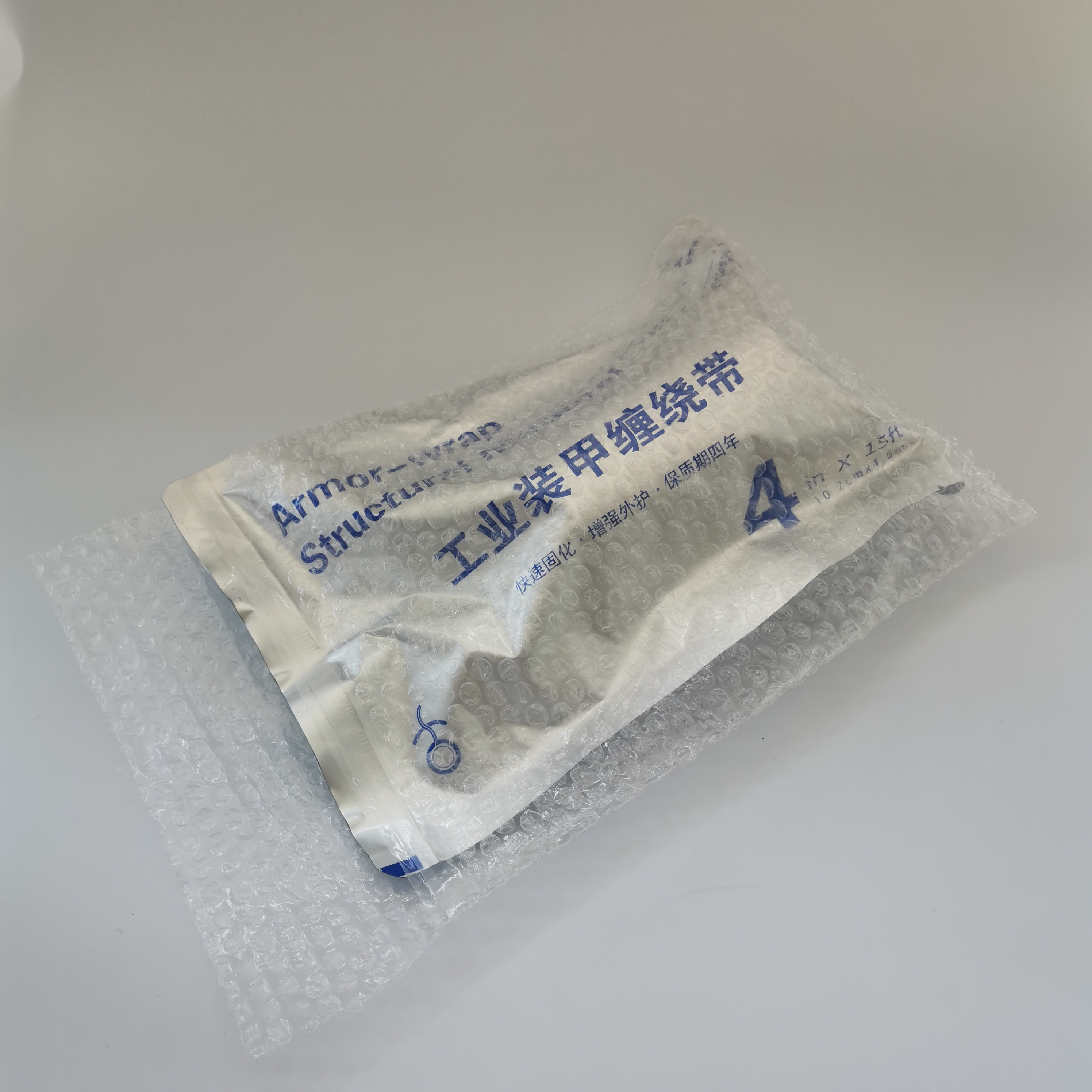

- Automotive wire wrap tape, also known as electrical insulation tape or wrapping tape, is a type of flexible,,(PVC)(PU)。、,。

Polyethylene, polyester, and polyimide are three different types of carrier materials used in adhesive tapes, each with its own advantages and characteristics.

- One of the primary uses of flame proof tape is in electrical and wiring applications. In areas where electrical currents are present, there is always a risk of an electrical fire occurring. Flame proof tape can be used to insulate and protect wires and cables from heat and flames, reducing the risk of a fire starting or spreading.

Tape adhesive types: Silicone vs. Acrylic vs. Rubber

3M rubber tapes have operating temperatures ranging from 176°F (80°C) to 221°F (105°C). Some, like Scotch® Linerless Rubber Splicing Tape 130C and Rubber Splicing Tape 23, have overloads temperatures up to 266°F (130°C). Because of this high heat attribute; there are many industrial settings where it is common to use rubber tape in lower voltage applications to moisture seal, pad and insulate:

It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure

It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure cloth wiring harness tape. This makes it an essential component in any electrical system where safety is a top priority.

cloth wiring harness tape. This makes it an essential component in any electrical system where safety is a top priority.

fireproof tape. By using this tape to seal off dangerous areas or block the spread of fire, responders can work more effectively to contain and extinguish fires, potentially saving lives and property.

Repair Needs: Assess the nature and extent of your repair requirements. Each tape is best suited for different types of repairs.

What Is a Control Box?

The colors will not yellow with age. Available widths range from one-fourth of an inch (6 millimeters) to 54 inches (1,372 millimeters).

Another noteworthy property is its excellent elasticity and flexibility, which ensures that it can be easily manipulated into different shapes and sizes. Butyl rubber also exhibits good fire resistance and remains functional even at extreme temperatures, ranging from -20°C to 150°C. These properties make butyl rubber rolls not only durable but also suitable for a variety of demanding applications.

fireproof tape for fireplace. Its flexible nature allows it to conform to various surfaces, and it remains effective over time without losing its heat-resistant properties. It's a cost-effective solution that can significantly enhance fireplace safety without compromising on aesthetics.

fireproof tape for fireplace. Its flexible nature allows it to conform to various surfaces, and it remains effective over time without losing its heat-resistant properties. It's a cost-effective solution that can significantly enhance fireplace safety without compromising on aesthetics. Athletes and trainers often use it for injury prevention and support Athletes and trainers often use it for injury prevention and support

Athletes and trainers often use it for injury prevention and support Athletes and trainers often use it for injury prevention and support insulation cotton tape. Its breathable cotton base provides a comfortable, non-irritating wrap for muscles and joints, while the adhesive ensures it stays in place during rigorous physical activity.

insulation cotton tape. Its breathable cotton base provides a comfortable, non-irritating wrap for muscles and joints, while the adhesive ensures it stays in place during rigorous physical activity.

high temp insulation tape. In the automotive industry, it secures hoses and wires that could be susceptible to heat damage. In aerospace, it protects sensitive instruments from extreme temperature fluctuations encountered during re-entry into the Earth's atmosphere. In the construction of high-rise buildings, it shields against flames and heat, contributing to safer living conditions.

high temp insulation tape. In the automotive industry, it secures hoses and wires that could be susceptible to heat damage. In aerospace, it protects sensitive instruments from extreme temperature fluctuations encountered during re-entry into the Earth's atmosphere. In the construction of high-rise buildings, it shields against flames and heat, contributing to safer living conditions.In simple terms, a rubber based pressure-sensitive consists of a natural or synthetic rubber to which various tackifying resins are added along with plasticizers, antioxidants, pigments, and UV stabilizers. These formulations can be delivered to the coating machine dissolved in organic solvents, dispersed in water, or in molten form as a hot melt. Some synthetic elastomers are also curable by radiation such as UV or electron beam(EB).

In the world of DIY projects and home repairs, few products have gained as much notoriety and acclaim as Flex Tape. Marketed as a super-strong adhesive tape that can seal, bond, and repair virtually anything, Flex Tape truly lives up to its reputation. In this article, we will take a closer look at Flex Tape, focusing on the white variant in 4-inch by 5-foot dimensions, exploring its uses, benefits, and overall effectiveness.

Choosing a Quality Supplier

toughstripe floor tape. It can be used in a wide range of applications, from marking aisles and exits to creating barriers around hazardous materials. It's also an effective way to highlight important information, such as Caution Wet Floor or Exit, ensuring that everyone in your facility is aware of potential hazards.

toughstripe floor tape. It can be used in a wide range of applications, from marking aisles and exits to creating barriers around hazardous materials. It's also an effective way to highlight important information, such as Caution Wet Floor or Exit, ensuring that everyone in your facility is aware of potential hazards.3. Durability and Flexibility The tape needs to maintain its integrity under mechanical stress. It should be flexible enough to wrap around busbars securely while also being tough enough to resist wear and tear over time.

Used for insulation and cable management, it can withstand extreme temperatures and harsh conditions encountered in space travel Used for insulation and cable management, it can withstand extreme temperatures and harsh conditions encountered in space travel

Used for insulation and cable management, it can withstand extreme temperatures and harsh conditions encountered in space travel Used for insulation and cable management, it can withstand extreme temperatures and harsh conditions encountered in space travel self annealing tape. The tape's self-repairing nature ensures the integrity of critical systems, enhancing overall safety.

self annealing tape. The tape's self-repairing nature ensures the integrity of critical systems, enhancing overall safety.Moreover, Flex Tape is resistant to extreme temperatures, which plays a vital role in its effectiveness. Whether it is the frigid cold of winter or the sweltering heat of summer, the tape maintains its adhesive properties, ensuring that repairs remain intact throughout the year. This reliability brings peace of mind to users who rely on it for critical fixes.