- Applications of Automotive Electrical Tape Fabric

- Electrical Insulation – Polyethylene has good electrical insulation properties. It provides insulation and protection against electrical currents, making it suitable for electrical applications such as wire splicing or cable bundling.

- In the realm of home improvement, often the smallest details make the most significant impact. One such detail is the door seal, a simple yet effective solution to enhance energy efficiency, reduce noise pollution, and improve overall comfort within the home. The use of rubber strips for door seals is a practical approach that embodies both functionality and affordability.

Is Electrical Tape Heat Resistant?

- Moreover, vulcanizing tape finds widespread use in the construction industry

- The adoption of Arc Proof Tape also aligns with the growing emphasis on preventive safety measures in the industry. By providing a proactive shield against arc flashes, it not only safeguards personnel but also prevents equipment damage, minimizing downtime and potential financial losses.

Composition and Features

- 6. Conclusion

- 1. Improved Efficiency Adhesive cloth automotive wiring harness tape streamlines the wiring process by allowing for quick and easy installation. Its self-adhesive properties eliminate the need for additional fasteners or tools, reducing the time and labor required for installation.

- Devices used by the operator might be as simple as a push button or an indicator light or as complicated as a touch-screen display with additional controls. As a result, these HMIs can be more complex, but they also need additional computing components and software development.

- Moreover, butyl rubber's high durability means that weather stripping made from this material can withstand years of use without cracking or breaking down. This longevity makes it a cost-effective solution in the long run, especially when compared to less resilient alternatives that need more frequent replacements.

- Moreover, vulcanizing tape finds its application in automotive industries, where it is used to protect and repair hoses, seals, and wiring harnesses. Its resilience to extreme conditions makes it a reliable choice for vehicles that operate in varying weather conditions.

- 4. Temperature Resistance Waterproof butyl rubber tape can withstand extreme temperatures, ranging from -58°F to 257°F (-50°C to 125°C), making it suitable for use in a variety of climates and environments.

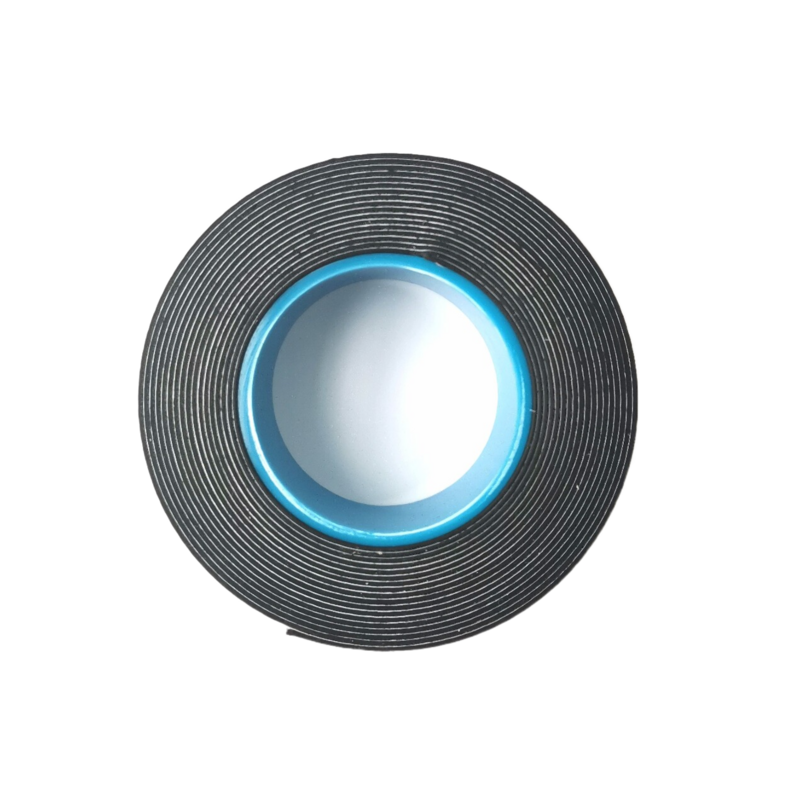

Its high shear strength makes window glazing tape a good option for mounting on vertical surfaces. It has good resistance to humidity, acid, oils, and grease. As a polyethylene foam tape, it has excellent conformability, even conforming to rough or uneven surfaces.

Your control box design should factor in numerous thermal aspects including the type of power supply and heat dissipation of your chosen materials. Ensure your box has elaborate airflow management features to maintain a safe operating temperature.

- Dimensional Stability – Polyester exhibits excellent dimensional stability, meaning it maintains its shape and size under various conditions. It is less prone to shrinkage or expansion, which is beneficial for applications requiring precise measurements or alignment.

Selecting the Perfect Control Box for You

One of the advantages of Flex Tape Black is its flexibility. Unlike traditional adhesive tapes, Flex Tape Black can bend and stretch, making it suitable for use on curved surfaces and around corners. This flexibility also helps to prevent the tape from cracking or peeling over time, ensuring a long-lasting and reliable repair.

- The Art of Self-Amalgamation A Journey Through Tape

- Flex Tape Black is incredibly easy to use, with a simple peel-and-stick application that requires no special tools or expertise. This makes it a convenient option for quick fixes and emergency repairs, allowing you to tackle unexpected problems with ease.

A supplier's reputation is often a testament to the quality of their products and customer service. Established suppliers with years of experience in the industry are more likely to provide high-quality butyl rubber tape. They will have the knowledge to advise on product specifications, application methods, and storage practices. It is beneficial to read customer reviews and ratings to gauge the supplier’s reliability and service quality.

(1) The thermal stability is 180 ℃. At this temperature, the product can be used safely for more than 10 years, saving many after-sales troubles;