Another advantage of security tek screws is their versatility. These screws come in a variety of sizes and styles, making them suitable for a wide range of applications

Quality control (QC) and quality assurance (QA) are fundamental components of the API manufacturing process. All steps of manufacturing must meet stringent regulatory requirements set by authorities such as the FDA or EMA. QC involves rigorous testing of raw materials and the intermediate and final products to ensure they meet predefined standards. These tests often include chemical analysis, microbiological testing, and stability studies. QA, on the other hand, encompasses the overall system of procedures and protocols that ensure consistent production quality, including documentation practices, employee training, and validation of equipment.

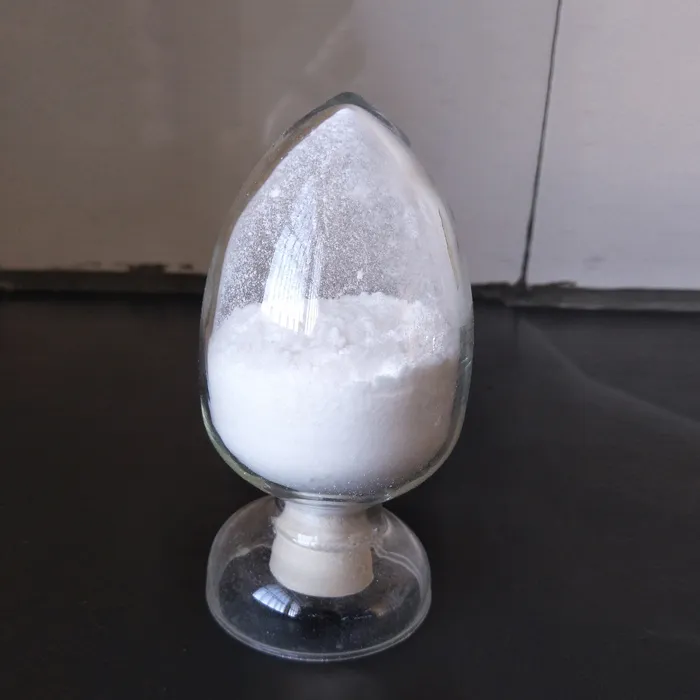

1% 3-Dimethylurea is a multifaceted compound with significant applications in biochemical research, agriculture, and pharmaceuticals. Its unique properties allow for a range of interactions with biological systems, contributing to advancements in our understanding of protein dynamics and improving agricultural practices. As research continues to unveil more about this versatile compound, its potential to impact various fields grows, paving the way for future innovations that harness its capabilities. Understanding and leveraging the properties of 3-Dimethylurea could lead to breakthroughs that address pressing challenges in health and food security, underscoring the importance of continued exploration in this realm.

Failure to comply with these regulations can result in severe repercussions, including product recalls, fines, and legal liabilities. As such, the integration of regulatory considerations into the API manufacturing process is paramount for ensuring the consistent quality and safety of pharmaceutical products.

Furthermore, public awareness campaigns can educate consumers about the risks of acrylamide in foods and its potential for leaching into water sources. This knowledge empowers the public to make informed decisions regarding food preparation techniques, thereby reducing overall acrylamide exposure.

2. Regulation and Quality DHEA is available over the counter in many countries, but its production is not as strictly regulated as prescription medications. This often leads to variability in the quality and concentration of DHEA in supplements. Consumers need to choose products from reputable manufacturers to ensure safety and efficacy.

Quality assurance is another critical aspect of API importation. The quality of an API directly affects the safety and effectiveness of the final product. As such, manufacturers must conduct thorough evaluations of their suppliers to ensure that they adhere to the necessary quality standards. This includes performing audits, reviewing certifications, and maintaining ongoing communication to address any quality concerns that may arise. Companies often invest in quality control measures, such as testing samples from suppliers, to mitigate risks related to contamination or variability in product potency.

Conclusion

As the demand for high-performance and durable plastic products continues to grow, the importance of light stabilizers in the plastics industry cannot be overstated. Ongoing research and development efforts are focused on creating new and more effective stabilizers that can provide superior protection while being environmentally friendly. Innovations in bio-based or biodegradable light stabilizers are on the horizon, offering the potential to further enhance the sustainability of plastics without compromising performance.