The electrical control box, on the other hand, is what?

Users can operate and monitor a piece of equipment using a Control Box, a physical interface. A container housing the mechanism or device that regulates and controls anything (mainly electrical or radio waves) within a system.

An electrical control box is analogous to a human body: Our bodies have essential organs that regulate and monitor our environment. Control panels for mechanical processes are similar in that they contain crucial electrical equipment for controlling and electronically monitoring the operation. Industrial equipment and machinery require well-defined functions and systematic control to meet diverse process objectives. In manufacturing equipment, control boxes provide these roles.

STRUCTURE OF CONTROL PANELS

The construction of a control panel consists of an enclosure and numerous distinct types of electrical components. These components define and arrange the various functions carried out by the control panel. These components include:

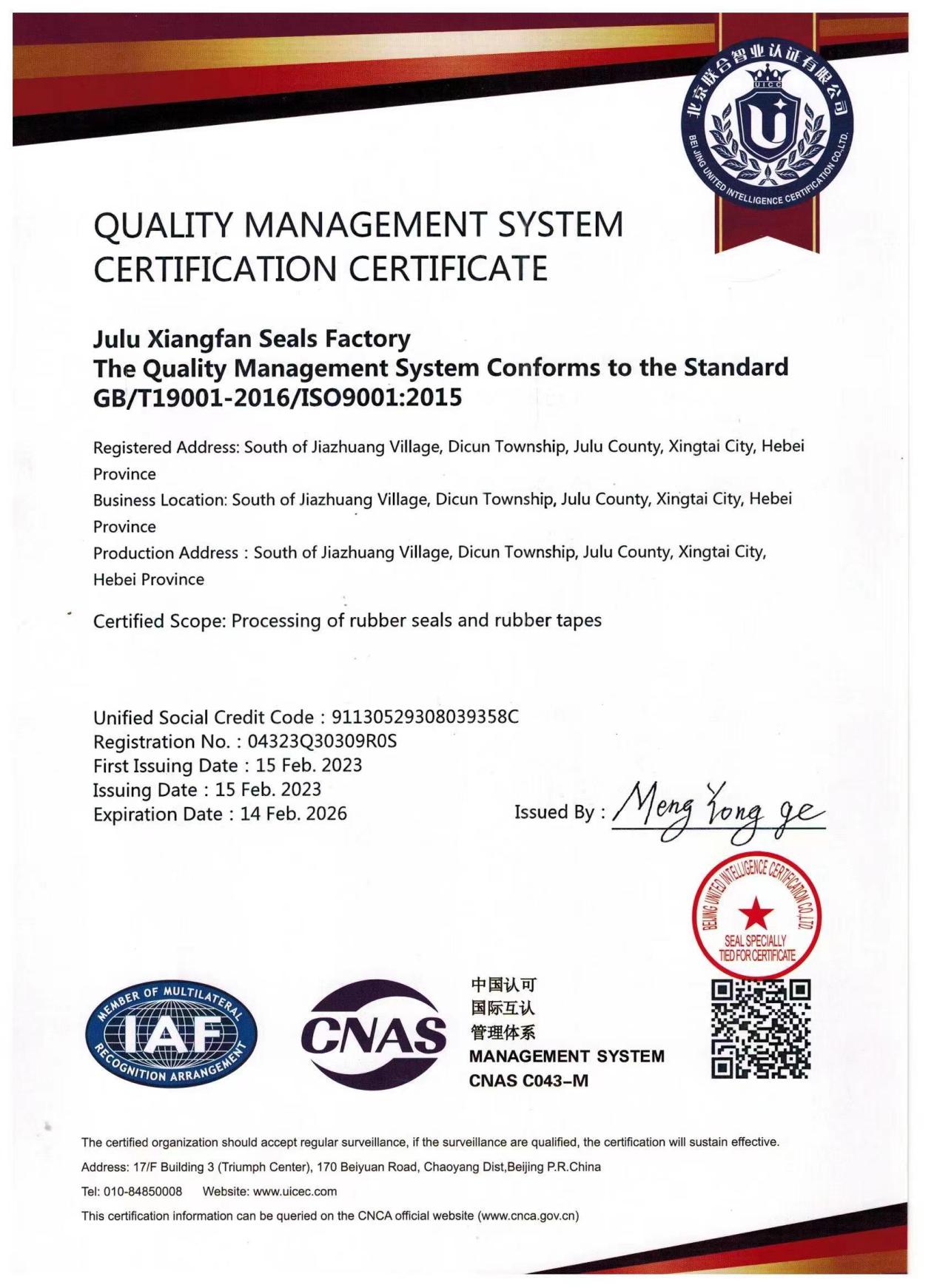

A lower price tag does not always equate to a lower standard of quality A lower price tag does not always equate to a lower standard of quality

A lower price tag does not always equate to a lower standard of quality A lower price tag does not always equate to a lower standard of quality Its ability to withstand extreme temperatures and weather conditions ensures that buildings remain watertight and well-insulated Its ability to withstand extreme temperatures and weather conditions ensures that buildings remain watertight and well-insulated

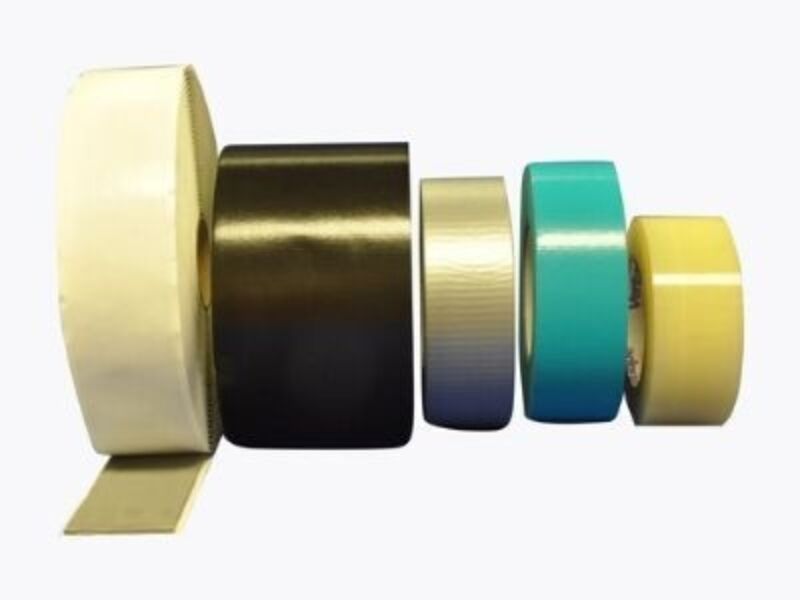

Its ability to withstand extreme temperatures and weather conditions ensures that buildings remain watertight and well-insulated Its ability to withstand extreme temperatures and weather conditions ensures that buildings remain watertight and well-insulated The bright colors and bold patterns used in most floor tapes also add a touch of personality and style to any space, making them an attractive addition to any décor The bright colors and bold patterns used in most floor tapes also add a touch of personality and style to any space, making them an attractive addition to any décor

The bright colors and bold patterns used in most floor tapes also add a touch of personality and style to any space, making them an attractive addition to any décor The bright colors and bold patterns used in most floor tapes also add a touch of personality and style to any space, making them an attractive addition to any décor