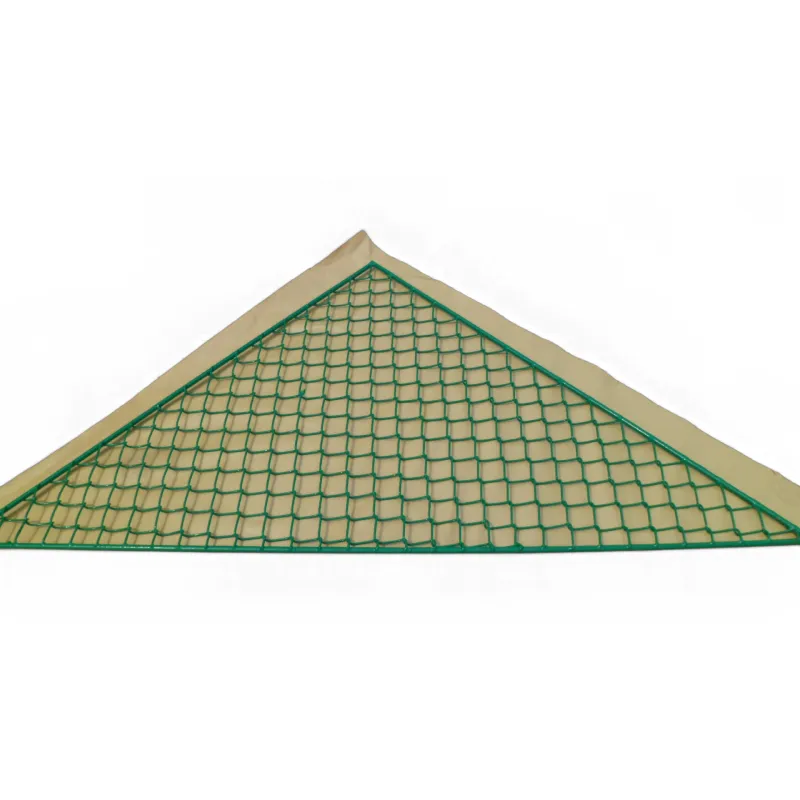

Perimeter safety nets are typically used in elevated work environments, such as high-rise buildings, bridges, and other construction sites where the risk of falling from heights is significant. Designed to catch falling objects and catch workers who may inadvertently slip, these nets are made from durable materials that can withstand substantial forces. Their ability to absorb the impact makes them a crucial element in reducing injuries related to falls.

Design and Load Capacity

In conclusion, concrete weight coating is a vital component in the pipeline industry, particularly for underwater applications. It serves to enhance the stability and protection of pipelines, reducing the likelihood of damage and leaks. By utilizing concrete weight coating, companies can ensure their pipelines maintain integrity, operate efficiently, and pose a lower risk to the environment and surrounding communities. As the demand for energy continues to grow, the importance of effective protective measures like concrete weight coating will remain a key focus in the development and maintenance of pipeline infrastructure.

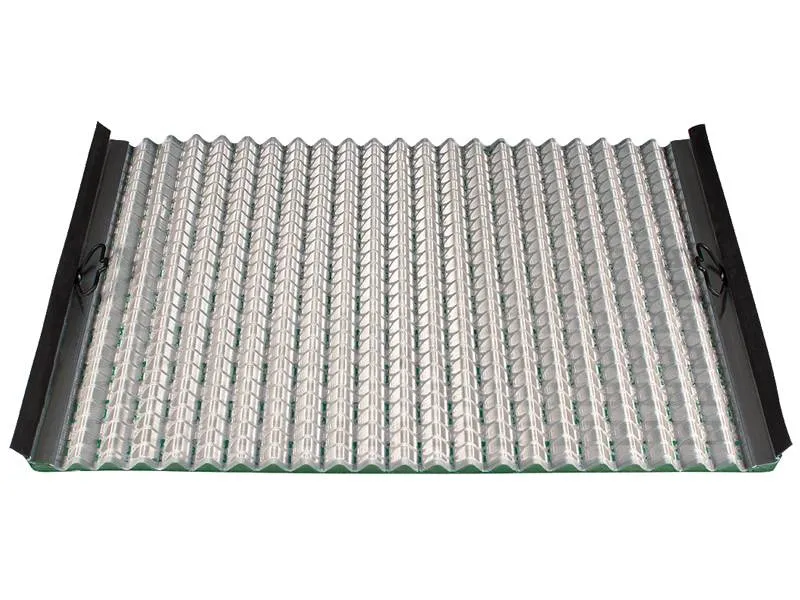

In conclusion, bar steel grating is a versatile and practical choice for various applications, offering significant advantages in durability, safety, maintenance, and aesthetics. Whether for industrial purposes or architectural elements, this material remains a popular option for builders and designers, reflecting a balance of functionality and style. Its continued evolution and adaptation ensure that bar steel grating remains relevant and essential in the ever-changing landscape of construction and design.

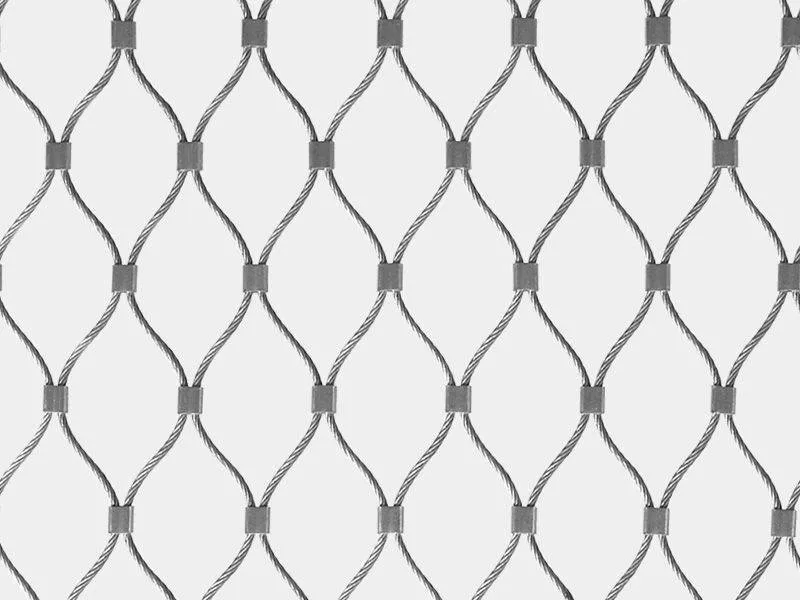

1. Material Quality The price of stainless steel bar grating largely depends on the quality of the stainless steel used. Grades 304 and 316 are the most common, with 316 being more resistant to chloride, making it more desirable for coastal or marine environments. Consequently, this higher resilience comes at a premium price.