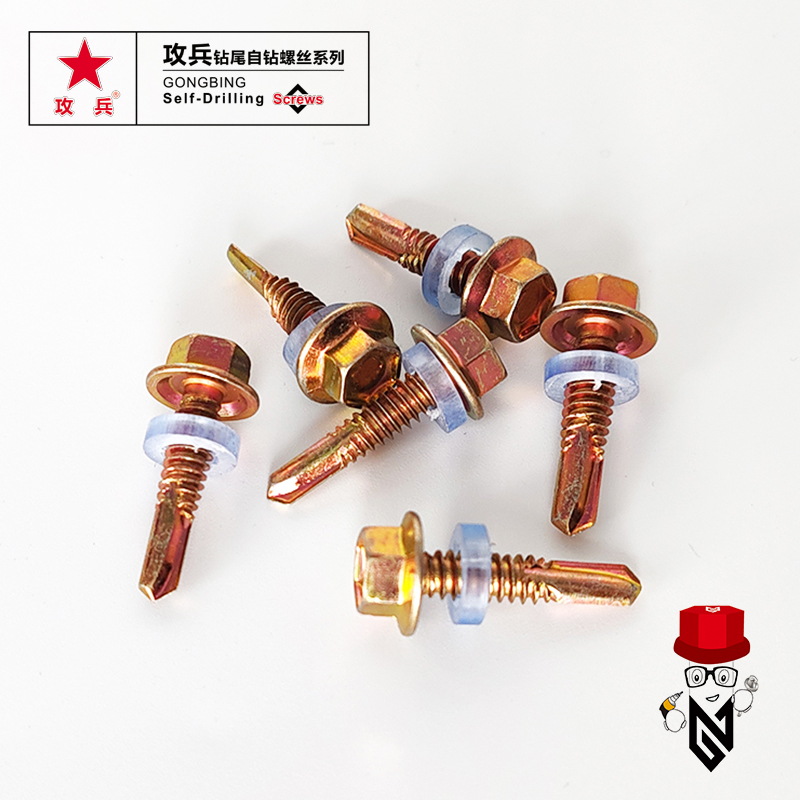

Another notable benefit is their resistance to moisture and chemicals, which makes them ideal for use in outdoor settings or in environments exposed to harsh chemicals. They maintain their integrity over time, providing a reliable and long-lasting hold They maintain their integrity over time, providing a reliable and long-lasting hold

One of the main advantages of hex head self-tapping sheet metal screws is their versatility

Moreover, 410 stainless steel screws exhibit good machinability, allowing for precise manufacturing and customization. Their ability to be easily formed and machined makes them a popular choice for manufacturers seeking flexibility in design and production Their ability to be easily formed and machined makes them a popular choice for manufacturers seeking flexibility in design and production

- viscous solution helps to suspend the active ingredient and prevent sedimentation

- Additionally, Chinese manufacturers have also focused on enhancing their production processes to ensure the sustainability and environmental friendliness of their HPMC products. By adopting green technologies and practices, these manufacturers are able to minimize their environmental impact and produce HPMC products that are in line with global sustainability standards.

Substitution of cellulose with ethyl-, methyl-, hydroxypropyl-, hydroxypropyl-methyl- and carboxymethyl groups may increase the resistance of cellulose to degradation. Resistance increases with the degree of substitution and is greatest when the substituent groups are evenly dispersed along the polymer chain. Most cellulose of the additive under assessment will therefore pass the intestine undigested and will excreted unchanged via faeces. Even when a high cellulolytic activity is present, as in the rumen, ethyl cellulose remains sufficiently resistant to degradation to be used as enteric coatings designed to protect methionine from rumen release (EFSA FEEDAP Panel, 2012c). Subsequent degradation in the post-ruminal tract is most likely to lead to high molecule weight breakdown products, with little probability of absorption.

It is also used in tile adhesives and grouts for its excellent bonding properties It is also used in tile adhesives and grouts for its excellent bonding properties

It is also used in tile adhesives and grouts for its excellent bonding properties It is also used in tile adhesives and grouts for its excellent bonding properties what does hpmc stand for.

what does hpmc stand for.Hydroxypropylmethyl cellulose is a cellulose ether with both methyl and hydroxypropyl functional group substitutions. Hydroxypropylmethyl cellulose (HPMC) is a nonionic thermoplastic polymer that dissolves in water to produce a solutions with a wide range in viscosity. It has greater gelling capacity than hydroxypropyl cellulose (HPC) and is more tolerant to salts and additives. HPMC is used as a thickening agent, stabilizer, emulsifier and film forming agent. Aging studies indicate that HPMC has very good stability with negligible discoloration or weight loss (Feller and Wilt 1990).

This slurry is then washed thoroughly to eliminate impurities and residual chemicals This slurry is then washed thoroughly to eliminate impurities and residual chemicals

This slurry is then washed thoroughly to eliminate impurities and residual chemicals This slurry is then washed thoroughly to eliminate impurities and residual chemicals mhec-methhyl hydroxyethyl cellulose factory. The purification process is vital to ensure the purity and stability of the final MHEC product.

mhec-methhyl hydroxyethyl cellulose factory. The purification process is vital to ensure the purity and stability of the final MHEC product. mhec-methhyl hydroxyethyl cellulose. Being derived from renewable resources like wood pulp, MHEC is biodegradable and does not accumulate in the environment. This feature positions MHEC as a sustainable alternative to synthetic polymers in many applications.

mhec-methhyl hydroxyethyl cellulose. Being derived from renewable resources like wood pulp, MHEC is biodegradable and does not accumulate in the environment. This feature positions MHEC as a sustainable alternative to synthetic polymers in many applications.

8. What are the main raw materials of hydroxypropyl methyl cellulose (HPMC)?

Answer: HPMC serves three functions in putty powder: thickening, water retention, and facilitating construction. It does not participate in any chemical reactions. The reasons for bubble formation are as follows:

hydroxyethyl cellulose. As a stabilizer and emulsifier, it helps maintain the consistency of lotions, shampoos, and toothpaste. Its ability to form films makes it useful in sunscreens, providing a protective barrier against UV rays.

hydroxyethyl cellulose. As a stabilizer and emulsifier, it helps maintain the consistency of lotions, shampoos, and toothpaste. Its ability to form films makes it useful in sunscreens, providing a protective barrier against UV rays.As with any ingredient, manufacturers must adhere to recommended dosage levels and quality standards to ensure the safety and effectiveness of the final product. Consumers should also follow recommended dosage instructions provided by their health care professional or as directed on the product label.

They maintain their integrity over time, providing a reliable and long-lasting hold They maintain their integrity over time, providing a reliable and long-lasting hold

They maintain their integrity over time, providing a reliable and long-lasting hold They maintain their integrity over time, providing a reliable and long-lasting hold

Their ability to be easily formed and machined makes them a popular choice for manufacturers seeking flexibility in design and production Their ability to be easily formed and machined makes them a popular choice for manufacturers seeking flexibility in design and production

Their ability to be easily formed and machined makes them a popular choice for manufacturers seeking flexibility in design and production Their ability to be easily formed and machined makes them a popular choice for manufacturers seeking flexibility in design and production