5

- Benefits of Automotive Electrical Tape Fabric

5. Sustainability Practices

There are several types of polyethylene film, each with a different density and use. Polyethylene tape is categorized by the tape’s density:

- Installation Techniques for Butyl Rubber Flashing

Applications

Flex Tape also showcases its versatility across various materials. Whether it's metal, plastic, wood, or even fabric, Black Flex Tape adheres remarkably well, providing a strong and lasting bond. This quality allows users to repair a wide range of items, from garden hoses and outdoor furniture to appliances and vehicles. The ability to use it in diverse settings—from home repairs to automotive applications—highlights its status as a multifunctional solution.

Tape adhesive types: Silicone vs. Acrylic vs. Rubber

Key Features and Benefits

Polyethylene Rubber Tape is composed of a polyethylene backing material with a rubber-based adhesive. Polyethylene is a thermoplastic polymer known for its excellent resistance to moisture, chemicals, and abrasion. The rubber adhesive provides strong adhesion to different surfaces.

The use of a vent or air handling units may be essential if the control box is situated in high atmospheric temperature area's. If temperature management is required, then air intakes and exhaust vents should be easily accessible so that filters may be accessed and replaced. Both the NEC and UL clearance requirements surrounding electrical wiring and heat-producing equipment must be considered.

Homeowners and industry professionals often view butyl tape as an all in one solution because of its multifunctionality. Follow on for a closer look at some of the primary uses of butyl tape.

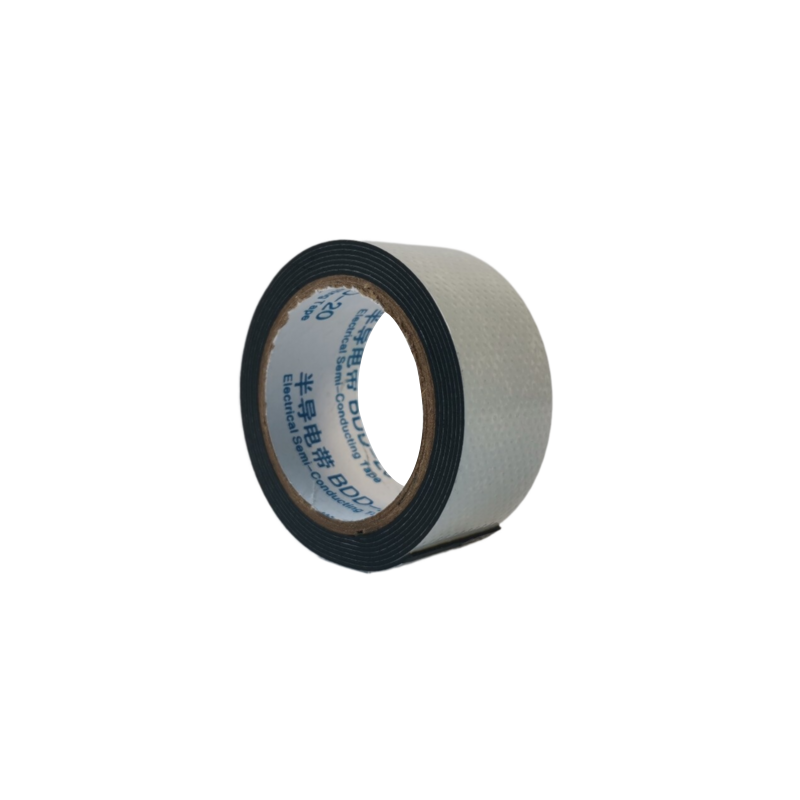

The Versatility and Benefits of Self-Fusing Rubber Tape

Key Advantages of Butyl Rubber Roofing Sheets

(4) Water absorption 0.9% (46 hours in H20 at 21 ℃)

Butyl rubber tape is a high-performance, waterproof adhesive tape made from butyl rubber, a synthetic rubber compound known for its excellent sealing properties. It possesses unique characteristics that make it an ideal choice for repair work, particularly in areas prone to water exposure. Unlike conventional tapes, butyl rubber tape is designed to remain flexible and durable, even under harsh weather conditions.

rubber strip for door seal. Homeowners can notice a reduction in energy bills as the strip helps to insulate the indoor environment, keeping heated or cooled air inside where it belongs. Moreover, the strip's soundproofing qualities contribute to a quieter, more peaceful home atmosphere. It also serves as a barrier against pollen, dust, and other allergens, creating a healthier living space for allergy sufferers.

rubber strip for door seal. Homeowners can notice a reduction in energy bills as the strip helps to insulate the indoor environment, keeping heated or cooled air inside where it belongs. Moreover, the strip's soundproofing qualities contribute to a quieter, more peaceful home atmosphere. It also serves as a barrier against pollen, dust, and other allergens, creating a healthier living space for allergy sufferers. Its flexibility also allows it to conform to uneven surfaces, ensuring a tight and secure fit every time Its flexibility also allows it to conform to uneven surfaces, ensuring a tight and secure fit every time

Its flexibility also allows it to conform to uneven surfaces, ensuring a tight and secure fit every time Its flexibility also allows it to conform to uneven surfaces, ensuring a tight and secure fit every time flex seal flex tape black 4 x 5.

flex seal flex tape black 4 x 5.Another critical application of yellow electrical tape is for safety signaling. In environments where electrical work is ongoing, it is imperative to indicate areas that are off-limits or require caution. By wrapping yellow tape around specific zones or equipment, workers can alert others to potential hazards. This visual cue is crucial for minimizing accidents and injuries on the job site, which is a critical aspect of workplace safety protocols.