- Automotive Industry Tek screws are also utilized in automotive assembly, where strength and reliability are paramount.

Another significant benefit is their cost-effectiveness

The head of a self-drilling decking screw is often designed with a star or square drive, which allows for better torque transfer and reduces the chances of stripping

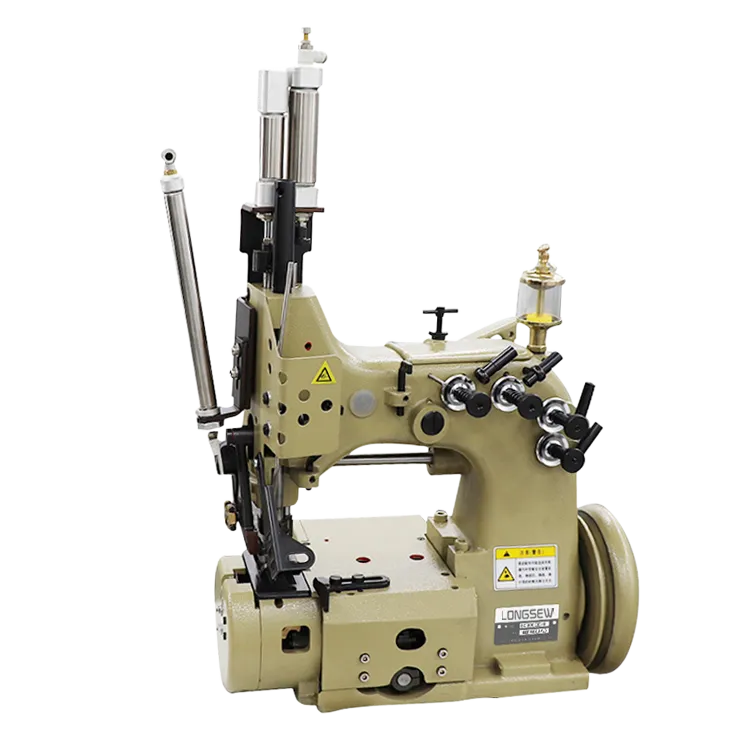

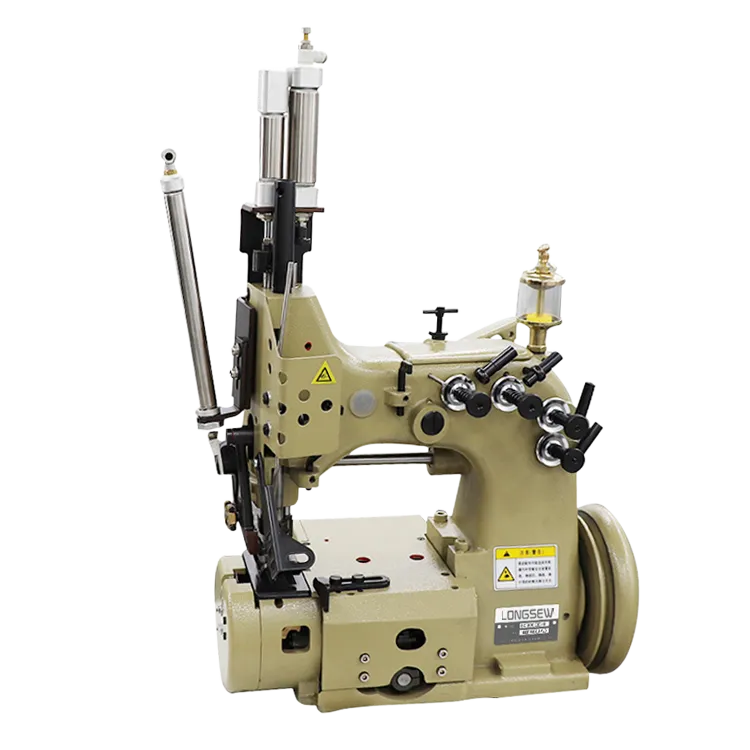

- One such tool is our special sewing machine. This machine is not just any ordinary sewing machine; it is a state-of-the-art piece of equipment that can handle even the most delicate and complex of fabrics. With its array of functions and features, our special sewing machine is a must-have for any serious seamstress or tailor.

When it comes to sewing leather, a few techniques can make your work easier. For instance, using a walking foot can help prevent the leather from sticking. If you do not have one, placing a piece of tissue paper or wax paper under the leather can also help it glide more smoothly. Additionally, always guide the leather with your hands without pulling it too hard, as this can create tension and result in uneven stitches.

1. Heavy-duty Construction The machine must be built to withstand the stress of sewing thick woven materials. A robust frame and quality components are crucial for longevity and reliability.

woven sack bag sewing machine

4. Cost-Effectiveness The improved efficiency in filling and discharging operations due to spout rosettes can lead to significant cost savings. By optimizing material flow, companies can reduce the time needed for loading and unloading, leading to better utilization of labor and equipment.

In addition to its speed and precision, the 2% needle industrial sewing machine is also known for its durability and reliability. This machine is built to withstand the rigors of constant use in an industrial setting, making it a valuable investment for businesses looking to increase their production capacity.

There are various types of industrial sewing machines tailored for leatherwork, including walking foot machines, post-bed machines, and cylinder-bed machines.

3. Easy Navigation The markings on the foot help sewers maintain consistency, especially when sewing intricate patterns or when sewing multiple layers of fabric.

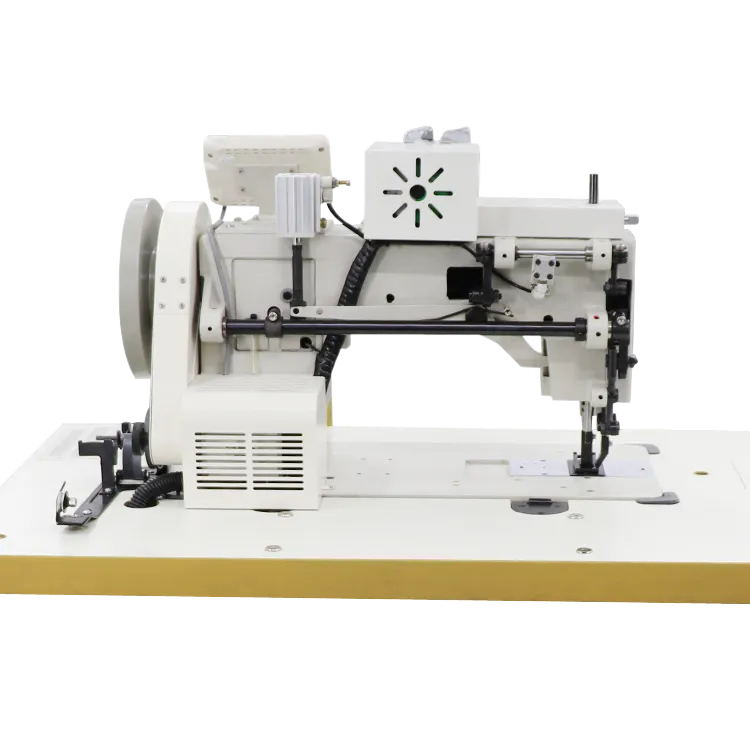

Investing in a dedicated sewing table has numerous benefits for upholstery projects

upholstery sewing table

The zigzag stitch is a versatile sewing technique that creates a stitch resembling a zigzag pattern. This functionality is vital for tasks that require stretching, such as sewing knit fabrics, as the zigzag stitch allows fabric to move without breaking the seams. Additionally, this stitch is perfect for finishing edges, preventing fraying, and adding decorative touches to sewing projects. Industrial zigzag sewing machines are built to handle heavy-duty materials, providing precision and durability that standard home machines may lack.

5% thread overlockers refer to machines that are designed to use 5% thread with a specific configuration that optimizes stitch quality and fabric handling. These machines often come with the ability to handle various types of fabric, from lightweight cotton to heavier knits, making them versatile for a range of sewing projects.

4. Budget Walking foot machines come at varying price points. Set a budget that aligns with your sewing needs. Remember, investing in a quality machine can save you money in the long run by reducing the need for repairs and ensuring a better sewing experience.

Heavy Duty Sewing A Comprehensive Guide

Why Use a Heavy-Duty Sewing Machine? Its Top Uses

Lock stitches are used in numerous sewing applications, from garment construction to quilting, due to their structural integrity

. Here are some common useslock stitch on sewing machine

Top Recommendations

commercial sewing machine needles. From heavy-duty needles for sewing leather and upholstery to fine needles for delicate fabrics like silk and chiffon, there is a needle for every sewing need. Choosing the right needle for the job is crucial for achieving professional and high-quality results in any sewing project.

Leveling button. You may have seen this feature on Look for machines with a leveling button on the general purpose foot. This is a tiny button (usually it’s black) on the presser foot. When pressed, it lifts the front of the presser foot up so that it can climb over the thickness change in fabric. This comes in handy when sewing through the multi-layer side seam or the multi-layer bottom seam in jeans. This is typically the area of sewing jeans that causes the most broken needles.

Conclusion