The advantages of using red and white floor marking tape extend beyond simple aesthetics. Here are some key benefits

FOR YOUR CABLE MANAGEMENT CONSIDERATION

This method is preferred for heavy-duty applications where maximum strength and reliability are required This method is preferred for heavy-duty applications where maximum strength and reliability are required

This method is preferred for heavy-duty applications where maximum strength and reliability are required This method is preferred for heavy-duty applications where maximum strength and reliability are required what is rubber splicing tape used for.

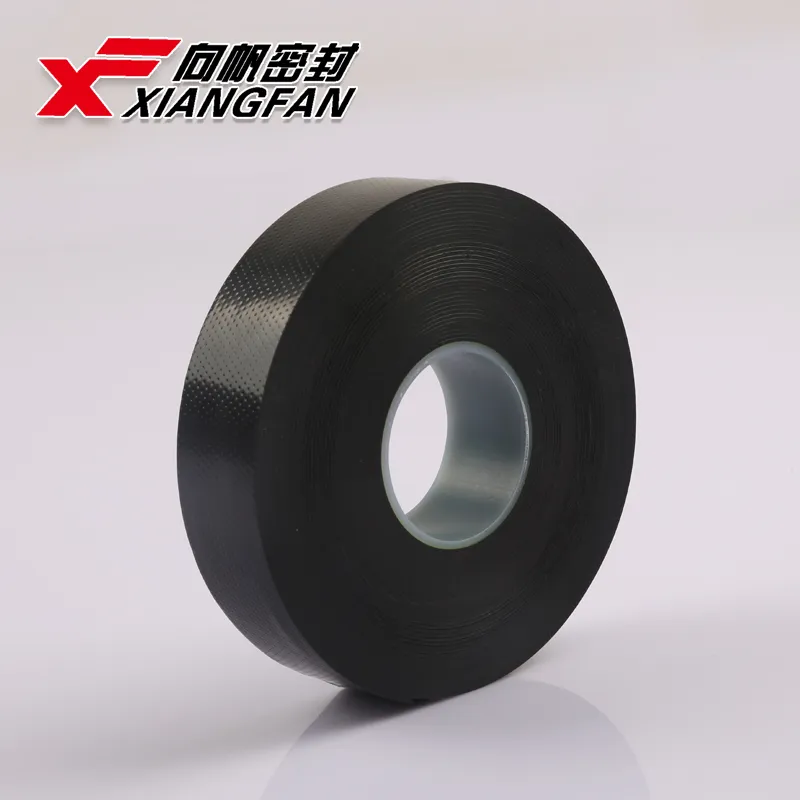

what is rubber splicing tape used for.PlB self-amalgamating Tape

Color: Black Red White Green Blue Yellow Grey

What is Butyl Rubber Sealant Tape?

5. Allow the tape to cure Once wrapped, let the tape sit for a few minutes to allow it to cure and create a strong bond. Depending on the type of tape, it may take anywhere from a few minutes to a few hours to fully cure.

Silicone self-adhesive tape, also known as silicone tape or self-fusing silicone tape, is a remarkable material that is made from high-quality silicone rubber. It boasts unique properties that set it apart from traditional tapes, such as electrical tape or duct tape. This silicone tape is self-fusing, which means that when it is stretched and wrapped around an object, it bonds to itself, creating a watertight and airtight seal without the need for adhesives or glues.

1. Prepare the surface Before applying the tape, make sure the surface is clean and dry. Remove any dirt, grease, or debris from the surface to ensure a proper seal.

It is available in 28 Models waterproof series, including full plastic protected plastic covers, half protected plastic covers with aluminum end panels, half protected plastic end covers, and wall-mounted flange. It can use the sticker instead of the printing.

There are some basic rules to follow when you’re selecting electrical tape.

yellow line marking tape. By using yellow tape to mark aisles, storage racks, and loading zones, workers can quickly locate products and navigate the space efficiently. This improves productivity and minimizes errors in inventory management.