- Furniture Assembly As a reliable option for joining wooden components, providing sturdy construction.

Unlike traditional vinyl or paper tapes, this tape is much more resistant to wear and tear, making it a great choice for applications where the tape will be subjected to rough handling or extreme temperatures Unlike traditional vinyl or paper tapes, this tape is much more resistant to wear and tear, making it a great choice for applications where the tape will be subjected to rough handling or extreme temperatures

Unlike traditional vinyl or paper tapes, this tape is much more resistant to wear and tear, making it a great choice for applications where the tape will be subjected to rough handling or extreme temperatures Unlike traditional vinyl or paper tapes, this tape is much more resistant to wear and tear, making it a great choice for applications where the tape will be subjected to rough handling or extreme temperatures black fabric electrical tape. It can also withstand exposure to moisture and other environmental factors without losing its adhesion or insulating properties.

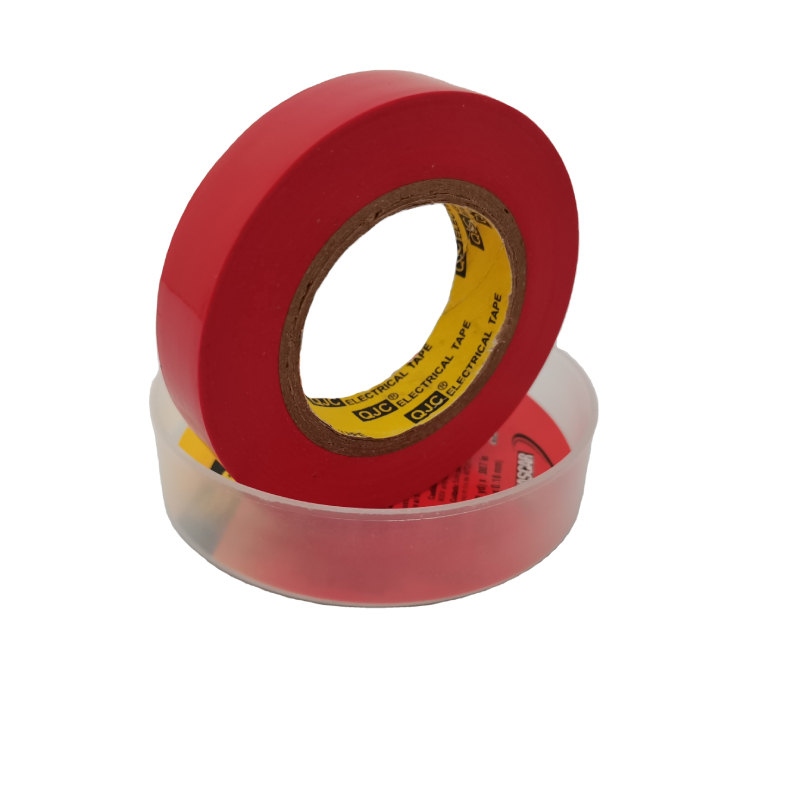

black fabric electrical tape. It can also withstand exposure to moisture and other environmental factors without losing its adhesion or insulating properties.This tape can be used for wire identification, seaming and splicing of films, and surface protection. Available colors are clear, black, white, and red. Widths range from one-fourth of an inch (6 millimeters) to 44 inches (1,118 millimeters).

Temperature Overload: 130°C

PVC electrical insulation tape is a vital component in various electrical applications, providing a reliable and efficient means of insulation, protection, and sealing. As the demand for quality electrical products continues to grow, particularly in emerging markets, the wholesale supply of PVC electrical insulation tape has gained significant attention. This article explores the features, applications, and benefits of PVC electrical insulation tape, focusing on its role in wholesale trade.

High Temperature Performance

This makes it an ideal solution for outdoor applications, such as sealing roof flashings, gutters, and other exposed areas This makes it an ideal solution for outdoor applications, such as sealing roof flashings, gutters, and other exposed areas

This makes it an ideal solution for outdoor applications, such as sealing roof flashings, gutters, and other exposed areas This makes it an ideal solution for outdoor applications, such as sealing roof flashings, gutters, and other exposed areas foil backed butyl tape.

foil backed butyl tape.Corrosion resistance – the dielectric strength of electrical tape is a measure of its electrical strength as an insulator. Vinyl electrical tape is available with differing dielectric strength making it ideal to use for insulating high-voltage wires over extended periods of time. By comparison, PVC electrical tape can be used in similar situations but care should be taken that its dielectric strength is sufficient to insulate active wires.

In conclusion, Flex Tape, particularly the waterproof clear variant, is a revolutionary product that meets the diverse needs of homeowners, DIY enthusiasts, and professionals alike. Its waterproof properties, ease of use, and versatility in applications make it a must-have item for any toolbox. Whether you are addressing urgent repairs or embarking on creative projects, Flex Tape provides peace of mind with its reliable performance, allowing you to tackle your challenges with confidence and ease. Don’t let leaks ruin your day; with Flex Tape, you have the ultimate solution at your fingertips.

Brand reputation plays a crucial role in determining insulation tape prices. Well-established brands with a history of quality and reliability tend to command higher prices due to consumer trust and perceived value. On the other hand, lesser-known brands may offer cheaper options, but they may not always meet the same quality standards. When considering insulation tape, it’s essential to balance brand reputation with cost; sometimes, investing in a trusted brand can save you money in the long run by reducing the need for repairs or replacements.

Electrical tape is made of PVC, which is a thermoplastic. This means that it will soften and melt when exposed to high temperatures. However, this doesn’t mean that electrical tape is flammable.

High voltage busbar insulation tape is an indispensable material in modern electrical installations. Its unique attributes—including high dielectric strength, temperature resistance, durability, and superior adhesive properties—make it essential for safeguarding both equipment and personnel. As the demand for electricity continues to rise and systems become increasingly complex, ensuring the integrity of high voltage insulation will remain a top priority in the electrical industry. In summary, the importance of high voltage busbar insulation tape cannot be overstated; it is a vital component in the safe and efficient operation of electrical systems, warranting careful consideration in any engineering project involving high voltage applications.

Butyl rubber is known for its exceptional impermeability to air, water, and other gasses, as well as its resistance to heat, chemicals, and UV radiation.

Butyl Sealant tapeis crafted from butyl rubber, a man-made material that was first synthesized during the early 1900s in order to strengthen traditional rubber adhesives. This innovative product surpasses natural rubbers in its capacity to stay sticky at far colder temperatures - an impressive feature that sets it apart from other adhesive materials.

In general, rubber based adhesives are not UV or oxidation resistant which is why they tend to be used predominantly in interior applications. Having said that, antioxidants and UV stabilizer packages can be added to the formulation to help mitigate these weaknesses. Some synthetic elastomers exhibit vastly improved UV stability over natural rubbers. Chemical resistance can also be problematic as is resistance to elevated service temperatures (typically 180- 200°F at the top end). The great strength of rubber-based adhesives is their wide formulation latitude. These adhesives can be compounded to be removable, repositionable, or extremely permanent. High strength foam bonding tapes can be made from rubber based adhesives or easily removable masking products can also be offered. Rubber based adhesive adhere to many surfaces including low surface energy plastics such as polypropylene and polyethylene. And to top it all off, rubber based adhesives are economical. They get the job done at a very fair price! Adhesive tapes made from rubber based adhesives have come a long way since Dr. Day’s first surgical tape and they still offer a cost-effective way to bond, seal, and protect.

tape for construction. Whether it's carpet protector tape to keep floors clean, masking tape to protect windows and trim during painting, or duct tape to patch up temporary barriers, tape plays a vital role in preventing damage to surfaces from dust, debris, or spills. This not only helps maintain the quality of the finished product but also saves time and money on costly repairs.

tape for construction. Whether it's carpet protector tape to keep floors clean, masking tape to protect windows and trim during painting, or duct tape to patch up temporary barriers, tape plays a vital role in preventing damage to surfaces from dust, debris, or spills. This not only helps maintain the quality of the finished product but also saves time and money on costly repairs.

1. Enhanced Fire Safety The most apparent benefit of fireproof gasket tape is its ability to resist flames and high temperatures. By utilizing this tape, businesses can significantly lower the risk of fire hazards in operational spaces. When applied correctly, fireproof gasket tape helps to create a barrier against the spread of fire, protecting equipment and personnel.

fireproof gasket tape

These specialized control boxes are primarily deployed in business buildings and their primary role is to manage air conditioning systems and lighting. They are relatively more complex than residential control boxes but their strength cannot be equated to that of industrial boxes.

Benefits of Using Fire-Resistant Electrical Tape

Silicone tape is a double-sided, non-adhesive rubber tape that is: