In artistic contexts, wrought iron often symbolizes strength and elegance, embodying the will of the artisans who shape it. When artists incorporate wrought iron into their works, they are not only showcasing their skills but also making a statement about endurance. The struggle against rust parallels the artist's journey—facing challenges but prevailing through perseverance and dedication.

3. Posts

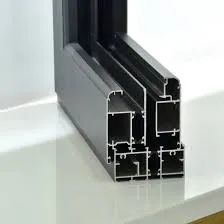

Aluminum fittings provide strength and sleekness, while composite doors combine the best features of multiple materials Aluminum fittings provide strength and sleekness, while composite doors combine the best features of multiple materials

Aluminum fittings provide strength and sleekness, while composite doors combine the best features of multiple materials Aluminum fittings provide strength and sleekness, while composite doors combine the best features of multiple materials window door fitting.

window door fitting. Their self-tapping feature reduces installation time and effort, making them a favorite among contractors and DIY enthusiasts alike Their self-tapping feature reduces installation time and effort, making them a favorite among contractors and DIY enthusiasts alike

Their self-tapping feature reduces installation time and effort, making them a favorite among contractors and DIY enthusiasts alike Their self-tapping feature reduces installation time and effort, making them a favorite among contractors and DIY enthusiasts alike They are also resistant to shearing and tensile forces, thus maintaining their integrity even under heavy loads They are also resistant to shearing and tensile forces, thus maintaining their integrity even under heavy loads

They are also resistant to shearing and tensile forces, thus maintaining their integrity even under heavy loads They are also resistant to shearing and tensile forces, thus maintaining their integrity even under heavy loads

1% by weight, significantly enhances iron's properties1% by weight, significantly enhances iron's properties

1% by weight, significantly enhances iron's properties1% by weight, significantly enhances iron's properties