...

2025-08-16 16:32

2571

...

2025-08-16 15:45

317

...

2025-08-16 15:25

151

...

2025-08-16 15:04

2175

The significance of chemical studies extends far beyond academic pursuits

...

2025-08-16 14:53

998

...

2025-08-16 14:46

157

...

2025-08-16 14:44

2454

...

2025-08-16 14:27

2537

...

2025-08-16 14:13

2801

...

2025-08-16 14:06

418

- Understanding the Heavy-Duty Jack Hammer Pricing A Comprehensive Guide

- Maintenance is another area where FRP ducts excel. They require minimal upkeep, as they do not rust, peel, or flake, and are resistant to mold and bacterial growth. This translates to long-term cost savings and improved system efficiency.

- 18. Oil-hardened hammer drill bits Heat-treated for added strength, they offer reliable performance in various drilling tasks.

- One of the most significant advantages of fiberglass drums is their adaptability. They are often favored by percussionists who need to switch between different drum heads quickly or adapt to varied acoustic environments. Their lightweight nature also makes them a popular choice for traveling musicians, reducing the load on tour buses and airplanes without sacrificing sound quality.

- The primary component of a rock drill is the drill bit. Made from high-strength steel or tungsten carbide, it's the sharp end that directly interacts with the rock. The bit's design, whether it's a button bit or a DTH (Down-The-Hole) bit, determines the drill's penetration rate and durability.

- In addition to their use in road construction and building construction, jack hammers are also used in mining and quarrying operations

- 2. Installation Practices Improper installation practices can also contribute to fiberglass duct corrosion. For instance, if the ducts are not properly sealed or secured, they may be more susceptible to water intrusion and subsequent corrosion. Therefore, it is crucial to follow the manufacturer's guidelines for installation and maintenance to ensure optimal performance and longevity.

- Initially, there is the direct cost of acquiring a jackhammer, which can range from a few hundred to several thousand dollars depending on its size, power, and features. Heavy-duty models designed for industrial applications are pricier, while smaller, handheld ones are more affordable but limited in their capabilities. Beyond the purchase price, maintenance costs, including regular servicing, replacement parts, and consumables like bits and blades, must be factored into the budget. These ongoing expenses ensure that the jackhammer continues to operate efficiently and safely.

small pneumatic jack hammer. Most models feature a set of ergonomic handles that make it comfortable to hold and control. This allows the operator to maintain a firm grip on the tool while still delivering powerful blows to the work surface.

jack hammer for sale near me. These establishments pride themselves on offering an array of models, accessories, and parts, ensuring that every customer finds a tool tailored to their specific needs. They are havens for professionals and hobbyists looking to acquire not just a tool, but a piece of craftsmanship that will endure through countless projects.

jack hammer for sale near me. These establishments pride themselves on offering an array of models, accessories, and parts, ensuring that every customer finds a tool tailored to their specific needs. They are havens for professionals and hobbyists looking to acquire not just a tool, but a piece of craftsmanship that will endure through countless projects. Their non-conductive nature also reduces the risk of electrical sparks, which can be a significant concern in oil storage facilities Their non-conductive nature also reduces the risk of electrical sparks, which can be a significant concern in oil storage facilities

Their non-conductive nature also reduces the risk of electrical sparks, which can be a significant concern in oil storage facilities Their non-conductive nature also reduces the risk of electrical sparks, which can be a significant concern in oil storage facilities fiberglass oil tank.

fiberglass oil tank.

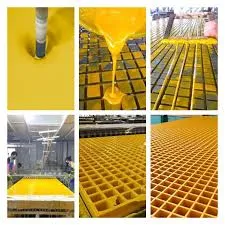

It is also poor maintenance, requiring only minimal repairs and upkeep. Making FRP grating ideal for harsh environments where it will be continually exposed.

hole drill bits. They are available in various sizes and lengths to suit different drilling depths.